Planetary ball mill

A planetary ball mill and ball mill jar technology, applied in grain processing and other directions, can solve the problems that the ratio between the grinding action and the impact action cannot be changed, the grinding effect is not ideal, and the impact action is not obvious, etc., which is beneficial to the mechanical alloying of abrasives. , good ball milling effect, improve the effect of ball milling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

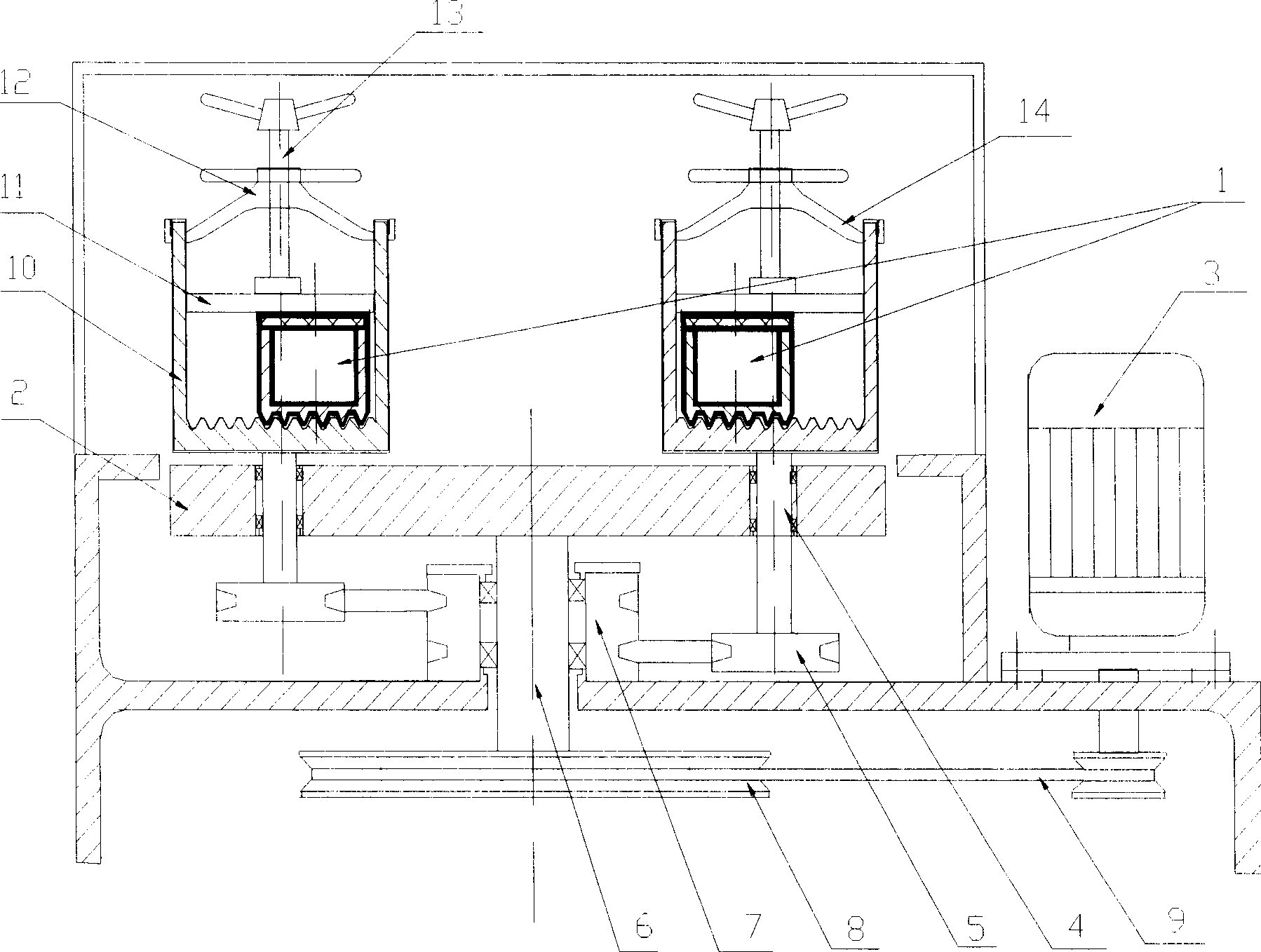

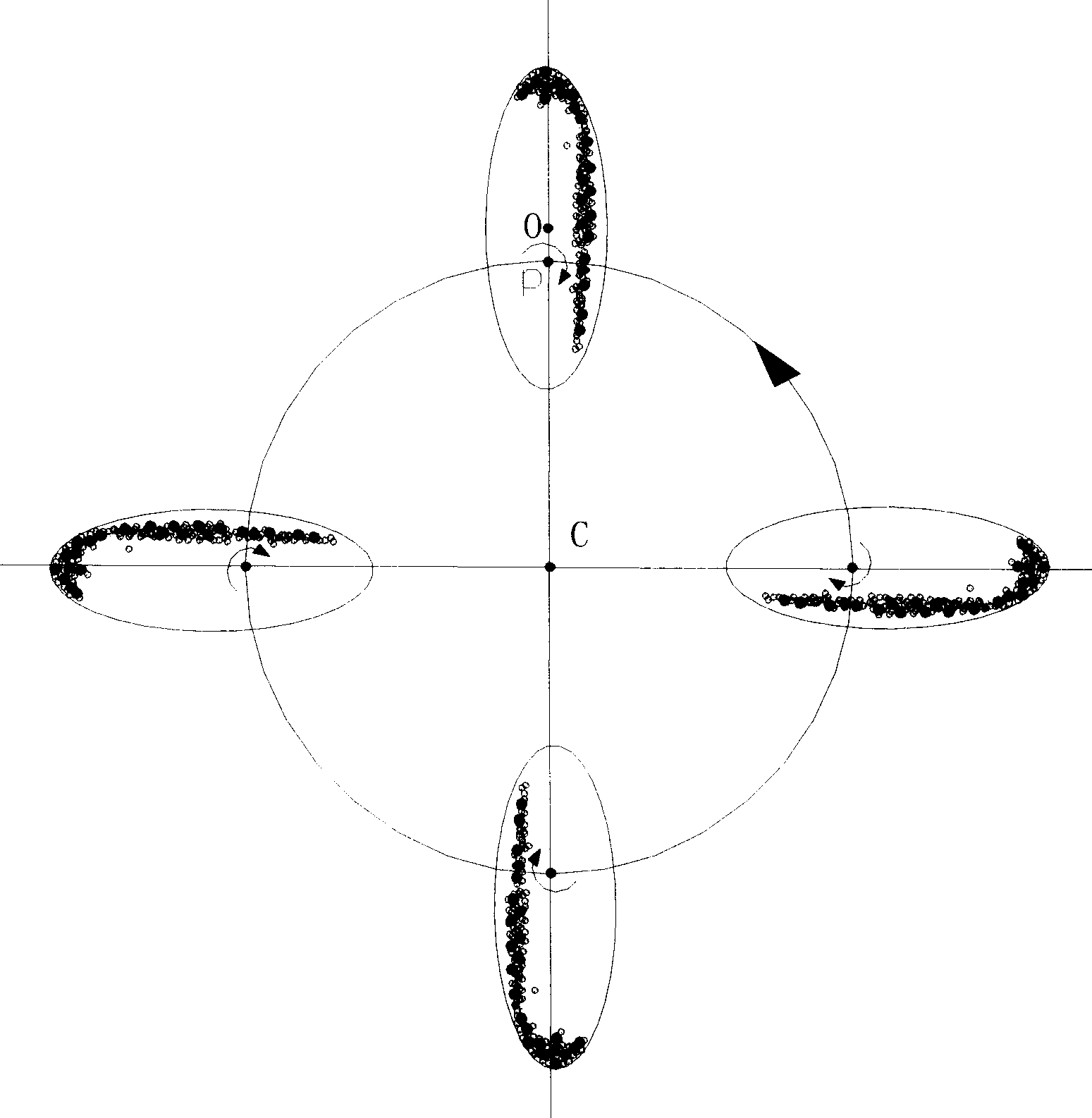

[0025] Such as figure 1 , 2 , 3 (A), the planetary ball mill includes a ball mill pot 1, a turntable 2, a transmission gear set, and a drive motor 3, and the ball mill pot 1 is in phase with the turntable 2 and the driven gear 5 of the drive gear set through the rotation shaft 4, respectively. connection, the turntable 2 is connected with the driving gear 7 of the transmission gear set through the revolution shaft 6, the revolution shaft 6 is connected with the driving motor 3 through the pulley 8 and the belt 9, the ball mill pot 1 is installed eccentrically, and the center line of the rotation shaft 4 is in line with the ball mill pot 1 The geometric centerlines of the cross section are parallel.

[0026] The tops of the respective rotating shafts are fixedly connected with a ball milling pot fastening device, and each ball milling pot fastening device includes a base 10, a gland 11 and a claw 12; The tank 1 is placed in the cup cavity of the base 10; the gland 11 is locat...

Embodiment 2

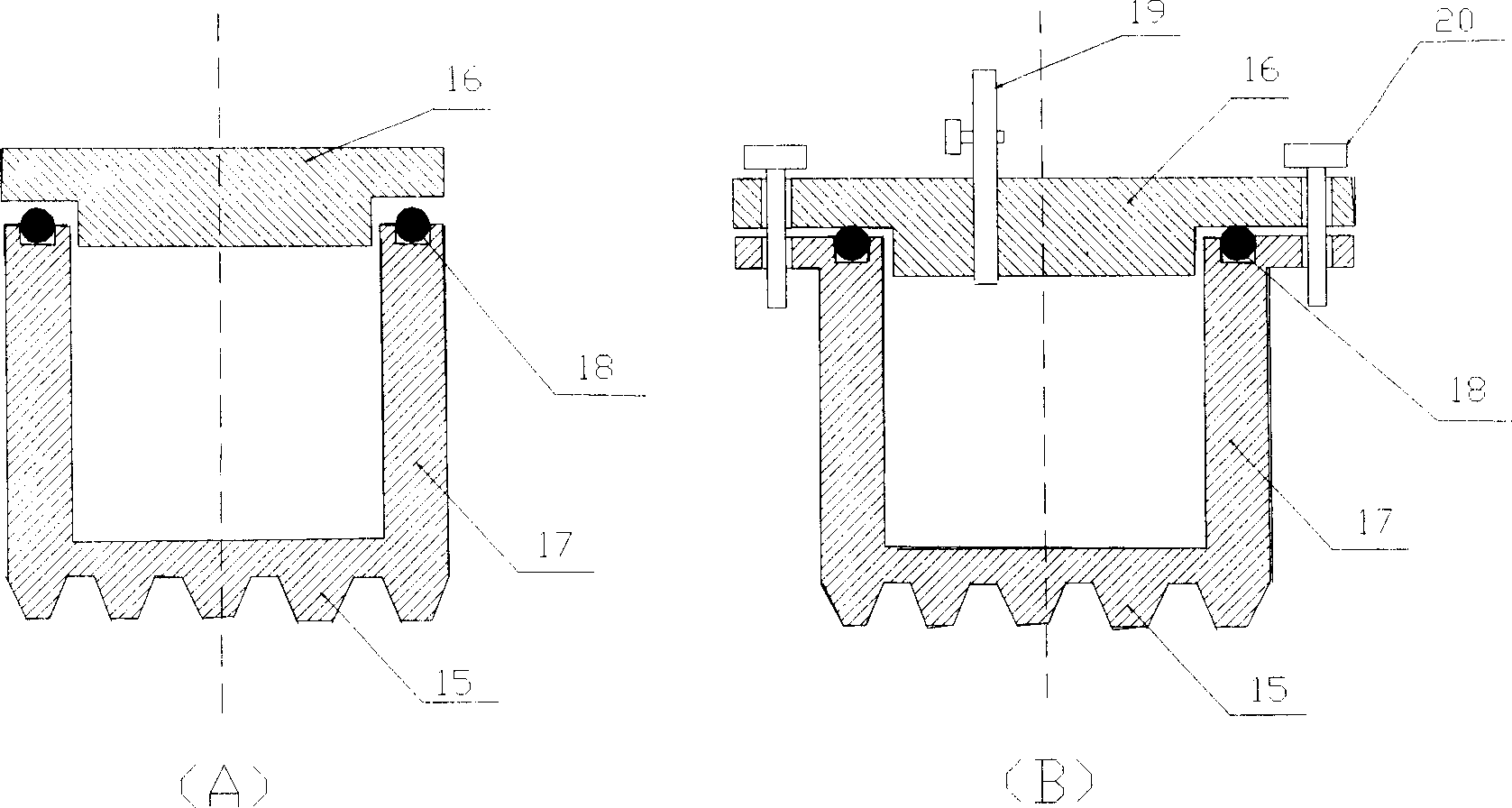

[0032] The structure of the planetary ball mill is the same as implementation one, wherein the cross-sectional shape of the ball mill jar 1 is as follows: Figure 4 (A) shown. The cross-section of the ball mill tank of this planetary ball mill is elliptical, with a minor semi-axis b and a major semi-axis a. When b / a=1, the grinding effect is the largest and the impact effect is the smallest; when b / a<1 and the value becomes smaller , the friction effect is reduced, and the impact effect is increased. In order to achieve a better ratio of friction force to impact force, the preferred range of the ratio of the minor semi-axis b to the major semi-axis a of the ellipse is: 0.2≤b / a<1.

Embodiment 3

[0034] The structure of the planetary ball mill is the same as implementation one, wherein the cross-sectional shape of the ball mill jar 1 is as follows: Figure 4 (B) shown. The cross-section of the ball mill tank of this planetary ball mill is an equilateral triangle with rounded transitions between adjacent sides, the radius of the rounded corner is r, and the length of the side is M. When r / M becomes smaller, the friction effect decreases and the impact effect increases. In order to achieve a better ratio of friction force to impact force, the preferred range of the ratio of the fillet radius r to the side length M is: 0.05≤r / M≤0.28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com