High-cleaning-power and high-viscosity friction type silicon dioxide and preparation method thereof

A technology of silica and cleaning power, applied in the field of high cleaning power and high viscosity friction silica and its preparation, can solve the problems of poor friction and thickening, poor low temperature performance of toothpaste, poor thickening performance, etc., to achieve Good thickening, improved friction performance, improved dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

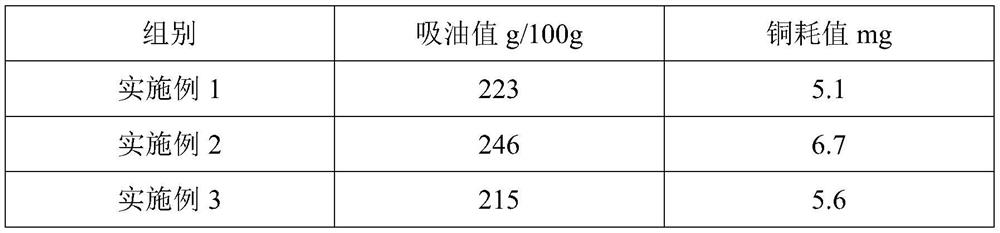

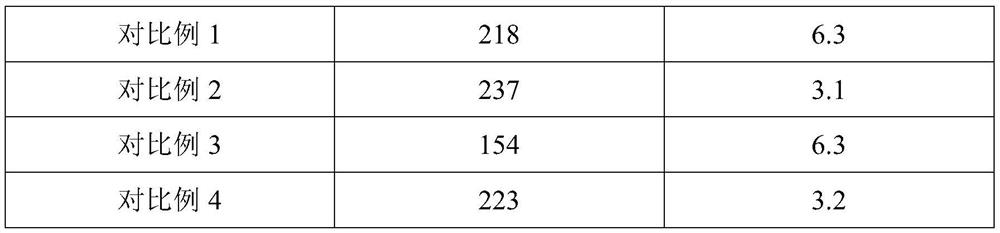

Examples

Embodiment 1

[0031] Example 1, a preparation method of high cleaning power and high viscosity friction type silica

[0032] The preparation method of described high-cleaning power high-viscosity friction type silica comprises the following steps:

[0033] S1, adding water to the water glass with a modulus of 2.5 to dilute, dissolve and age for 5h, then get the water glass after the aging treatment and add water to configure a water glass solution with a concentration of 0.85mol / L for subsequent use;

[0034] S2, configuration concentration is the sulfuric acid solution of 2.5mol / L, standby;

[0035] S3, add 12m in reaction tank 3 The mass percentage is 4% sodium sulfate solution, then add 20L of the water glass solution prepared in step S1, heat up to 55°C, turn on the stirring device and set the stirring frequency to 30Hz, then add 6kg of octanol, and stir evenly;

[0036] S4, under above-mentioned agitation condition, continue dripping the sulfuric acid soln that step S1 makes water gl...

Embodiment 2

[0038] Example 2, a preparation method of high-cleaning power and high-viscosity friction-type silica

[0039] The preparation method of described high-cleaning power high-viscosity friction type silica comprises the following steps:

[0040] S1, dilute, dissolve and age the water glass with a modulus of 3.0 with water for 6.5 hours, then take the aged water glass and add water to form a water glass solution with a concentration of 1.34mol / L for subsequent use;

[0041] S2, configuration concentration is the sulfuric acid solution of 3.2mol / L, standby;

[0042] S3, add 12m in reaction tank 3 The mass percentage is 5.6% sodium sulfate solution, then add 75L of the water glass solution prepared in step S1, heat up to 61°C, turn on the stirring device and set the stirring frequency to 35Hz, then add 12kg of octanol, and stir evenly;

[0043] S4, under above-mentioned agitation condition, continue dripping the sulfuric acid soln that step S1 makes water glass solution and step S...

Embodiment 3

[0045] Example 3, a preparation method of high-cleaning power and high-viscosity friction-type silica

[0046] The preparation method of described high-cleaning power high-viscosity friction type silica comprises the following steps:

[0047] S1, adding water to the water glass with a modulus of 3.5 to dilute, dissolve and age for 8 hours, then take the aged water glass and add water to configure a water glass solution with a concentration of 1.8mol / L for subsequent use;

[0048] S2, configuration concentration is the sulfuric acid solution of 4.5mol / L, standby;

[0049] S3, add 12m in reaction tank 3 The mass percentage is 8% sodium sulfate solution, then add 100L of the water glass solution prepared in step S1, heat up to 65°C, turn on the stirring device and set the stirring frequency to 40Hz, then add 15kg of octanol, and stir evenly;

[0050] S4, under above-mentioned agitation condition, continue dripping the sulfuric acid solution that step S1 makes water glass soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com