High-loading-capacity and high-cleanliness friction type silicon dioxide for tooth powder and preparation method of silicon dioxide

A technology of silicon dioxide and load force, applied in the direction of silicon dioxide, silicon oxide, cosmetic preparations, etc., can solve the problems of small water absorption, easy agglomeration of dentifrice, easy to agglomerate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

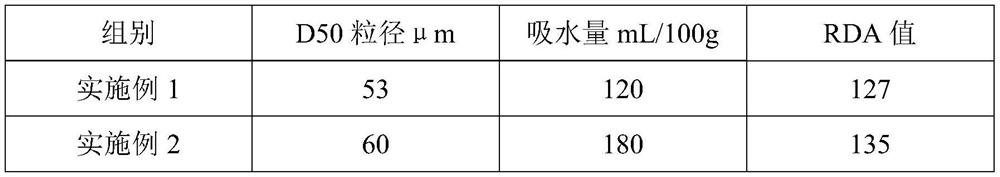

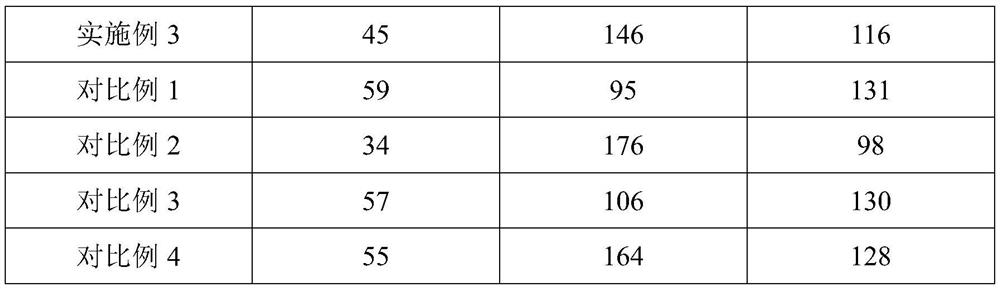

Examples

Embodiment 1

[0029] Example 1. A preparation method of silicon dioxide for high-load-loading and high-cleaning abrasive tooth powder

[0030] The preparation method of silicon dioxide for the high-load-loading and high-cleaning abrasive tooth powder comprises the following steps:

[0031] S1. After liquefying solid sodium silicate with a modulus of 3.5 at high temperature, add water to form a sodium silicate solution with a concentration of 3.0mol / L;

[0032] S2, configuration concentration is the sulfuric acid solution of 8.0mol / L;

[0033] S3. Add a mass percentage of 0.95% sodium dodecylsulfonate solution to the reactor, the amount added is 40% of the volume of the sodium silicate solution, heat up to 85°C, open the stirring paddle in the reactor and set the stirring frequency 40Hz, in the state of stirring, dropwise the sodium silicate solution that step S1 makes and the sulfuric acid solution that step S2 makes, the dripping amount of sodium silicate solution is 13.5m 3 , the droppi...

Embodiment 2

[0035] Embodiment 2, a kind of preparation method of silicon dioxide for high load force high cleaning friction type dentifrice

[0036] The preparation method of silicon dioxide for the high-load-loading and high-cleaning abrasive tooth powder comprises the following steps:

[0037] S1. After liquefying solid sodium silicate with a modulus of 2.5 at high temperature, add water to form a sodium silicate solution with a concentration of 2.6mol / L;

[0038] S2, configuration concentration is the sulfuric acid solution of 6.5mol / L;

[0039] S3. Add a mass percentage of 0.57% sodium dodecylsulfonate solution to the reactor, the amount added is 31% of the volume of the sodium silicate solution, heat up to 83°C, open the stirring paddle in the reactor and set the stirring frequency 36Hz, in the state of stirring, add dropwise the sodium silicate solution that step S1 makes and the sulfuric acid solution that step S2 makes together, the dripping amount of sodium silicate solution is ...

Embodiment 3

[0041] Example 3, a preparation method of silicon dioxide for high-load-loading and high-cleaning abrasive tooth powder

[0042] The preparation method of silicon dioxide for the high-load-loading and high-cleaning abrasive tooth powder comprises the following steps:

[0043] S1. After liquefying solid sodium silicate with a modulus of 1.5 at high temperature, add water to form a sodium silicate solution with a concentration of 1.5mol / L;

[0044] S2, configuration concentration is the sulfuric acid solution of 4.0mol / L;

[0045] S3. Add 0.10% sodium dodecylsulfonate solution to the reaction kettle in an amount of 20% of the volume of the sodium silicate solution, raise the temperature to 70°C, open the stirring paddle in the reaction kettle and set the stirring frequency 30Hz, in the state of stirring, add dropwise the sodium silicate solution that step S1 makes and the sulfuric acid solution that step S2 makes together, the dripping amount of sodium silicate solution is 11.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com