Electrically closed solenoid valve

A technology for solenoid valves and valve sleeves, applied in the field of solenoid valves, which can solve the problems of deterioration of the adjustability of solenoid valve 1 and increase in the direction of magnetic force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

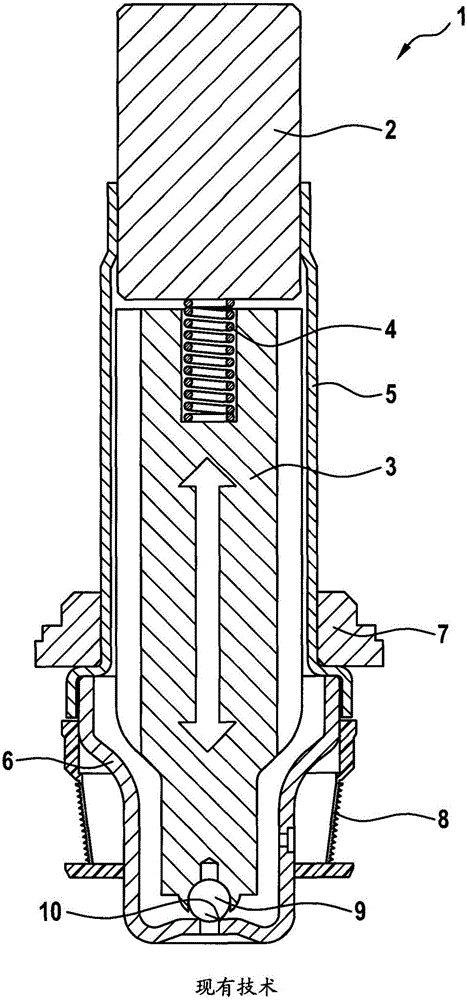

[0041] figure 1 A schematic sectional view of a prior art solenoid valve 1 for a hydraulic system of a vehicle is shown. Description 1 of such a solenoid valve can be seen in the description of the prior art.

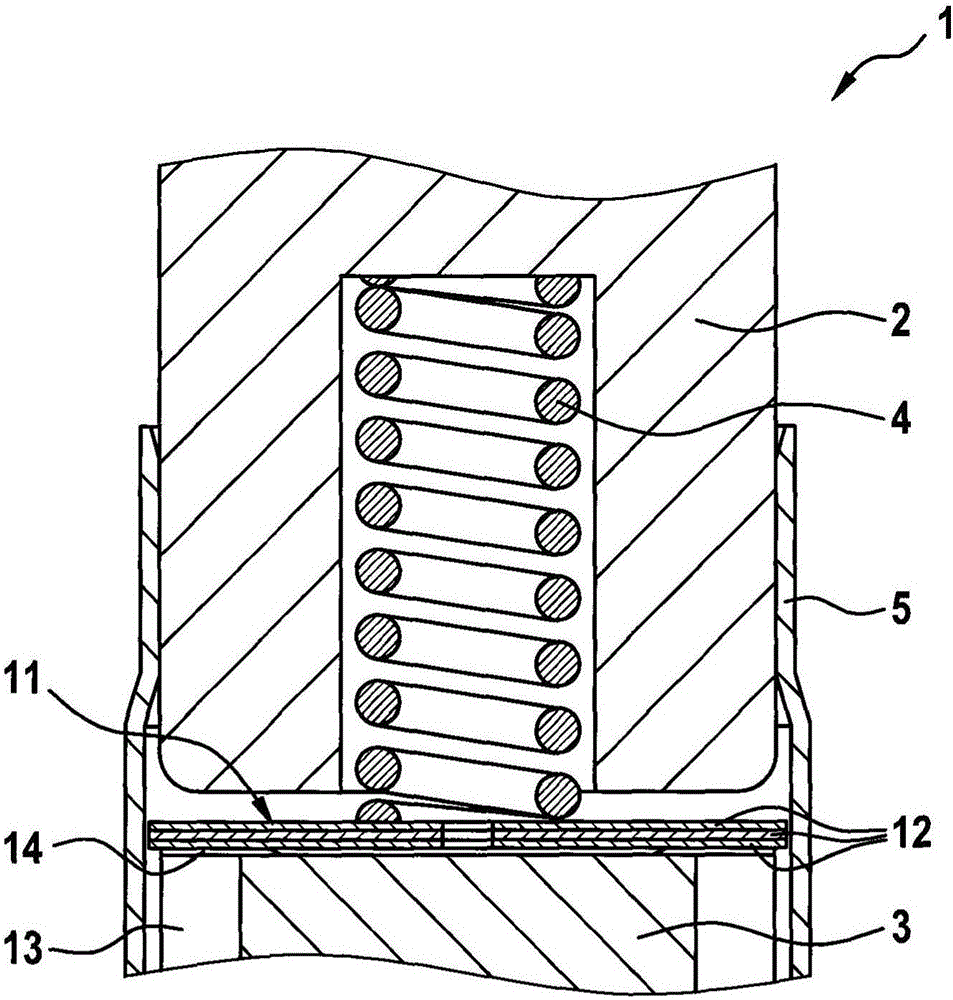

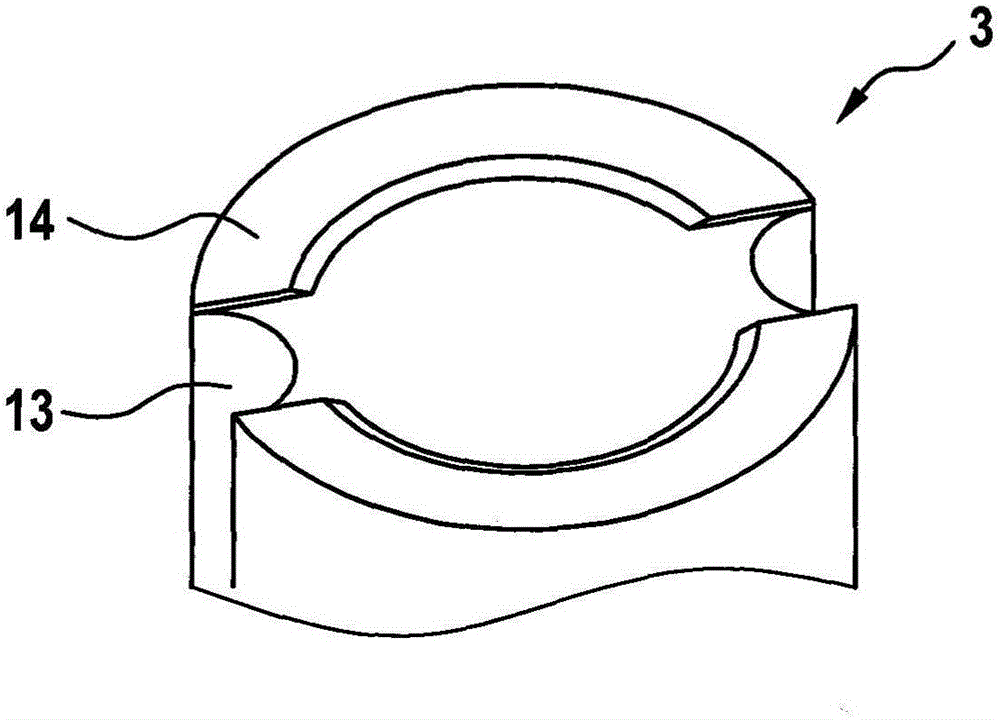

[0042] figure 2 A part of a cross-sectional view of an embodiment of a solenoid valve 1 with a mechanism 11 for hydraulic damping is shown. A specially designed spring washer 12 is used as the mechanism 11 . Three spring washers 12 are used in the embodiment shown. Here, the spring washer 12 , ie the mechanism 11 , is positioned directly on the armature 3 . In the radially outer region, the armature 3 has an armature groove 13 which is continuous over the entire length of the armature 3 . In the embodiment shown, two armature grooves 13 are formed. The armature 3 also has an armature step 14 in the outer region, on which the mechanism 11 rests directly. Due to the armature step 14 , a radially built-in cavity is formed between the mechanism 11 and the armature 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com