Automatic powder mixing device and method for glass spacer powder

A technology for powder isolation and powder mixing, which is applied to chemical instruments and methods, mixers with rotating mixing devices, mixer accessories, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The content of the present invention will be further described below in conjunction with the accompanying drawings.

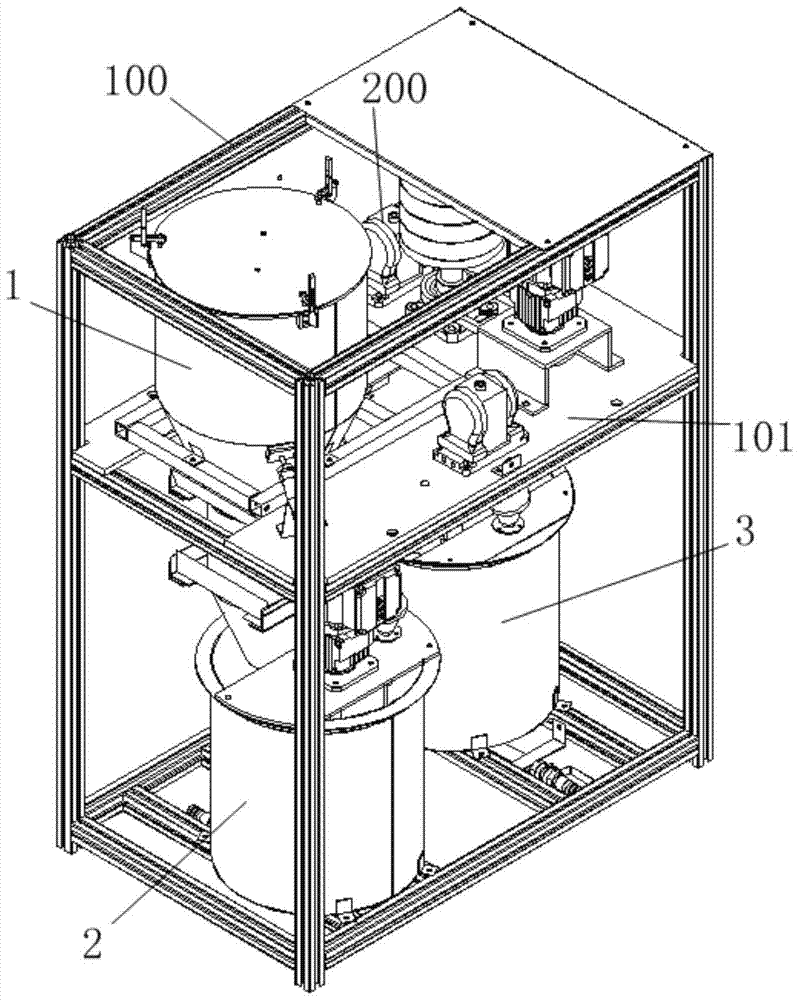

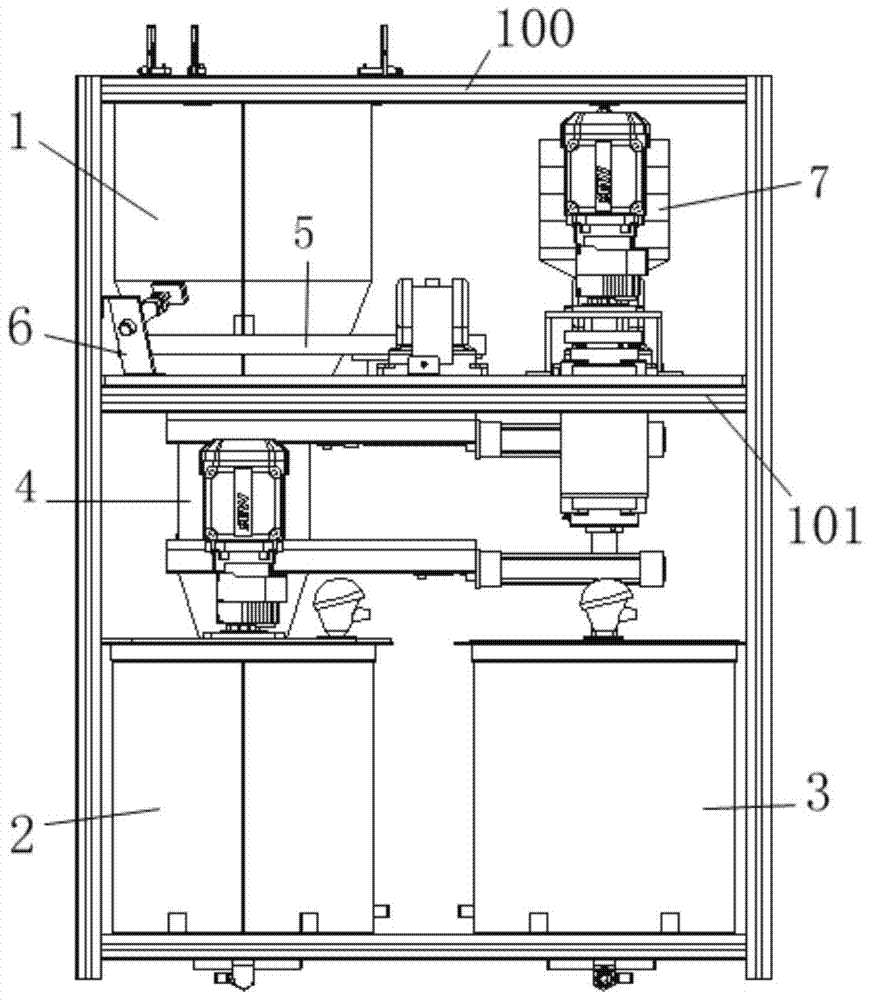

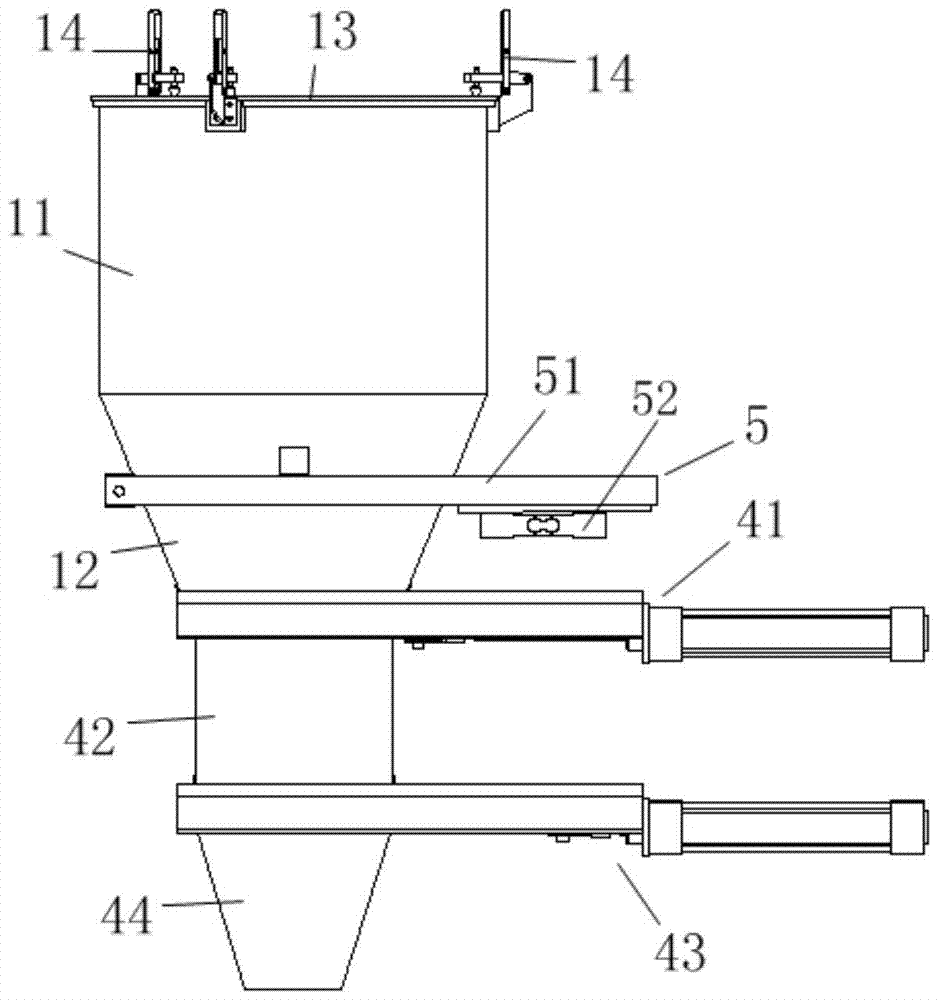

[0043] Such as figure 1 As shown, an automatic powder dispensing device for glass spacer powder according to the present invention is used for automatic powder dispensing of glass spacer powder, which includes a powder storage tank 1, a powder mixing tank 2, a discharge tank 3 and an external water supply device (not shown), the powder storage barrel 1, the powder mixing barrel 2 and the discharge barrel 3 are connected in sequence, and the external water supply device (not shown) is connected with the powder mixing barrel 2; wherein, the powder storage barrel 1 is used for storing Powdered glass spacer powder, the glass spacer powder in the powder storage tank 1 can enter the powder mixing tank 2, the external water supply device can add an appropriate amount of water to the powder mixing tank 2, and the powder mixing tank 2 is used to put the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com