Repair welding method of austenite stainless steel casted nuclear pump shell

A repair welding technology for austenitic stainless steel, applied in the field of defect repair, can solve problems such as welding stress direction and uneven distribution, achieve reasonable size and distribution, avoid weld cracks, and improve intergranular corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Defect detection and treatment: Perform preliminary grinding and removal of possible defects in the sample. The grinding materials are only allowed to be emery, aluminum oxide, diamond, etc. and previously used on stainless steel or nickel-based materials, and use penetrant testing (PT) method inspection to ensure that there are no possible and hidden defects.

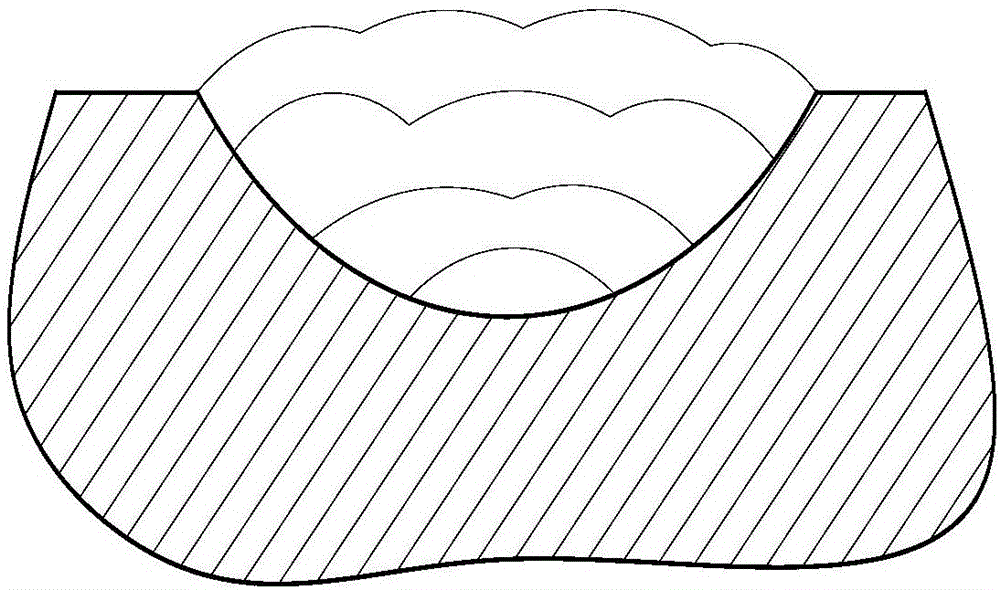

[0033] Step 2: Welding groove treatment: Divide the samples into two batches, one batch will finely grind the repair welding pits of the samples after removing the defects into an oval shape to ensure that the welding grooves are symmetrical and the arc is moderate and not greater than 120 degrees. The roughness is less than 12.5, and the groove depth is not greater than the radius of the minor axis of the ellipse Then the polished area was cleaned with acetone to avoid introducing other impurities, and the other batch was left untreated as Comparative Example 1.

[0034] The third step: welding rod tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com