Method for magnetic-field-assisted laser engineered net shaping of Al2O3-based eutectic ceramic cutting tool

A laser near-net-shaping, ceramic tool technology, applied in the field of tool manufacturing, can solve the problems of high requirements for ceramic slurry, low precision of molded parts, inconvenient machining, etc., to improve production efficiency, prevent pores and cracks, and improve Effects of thermal conductivity and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

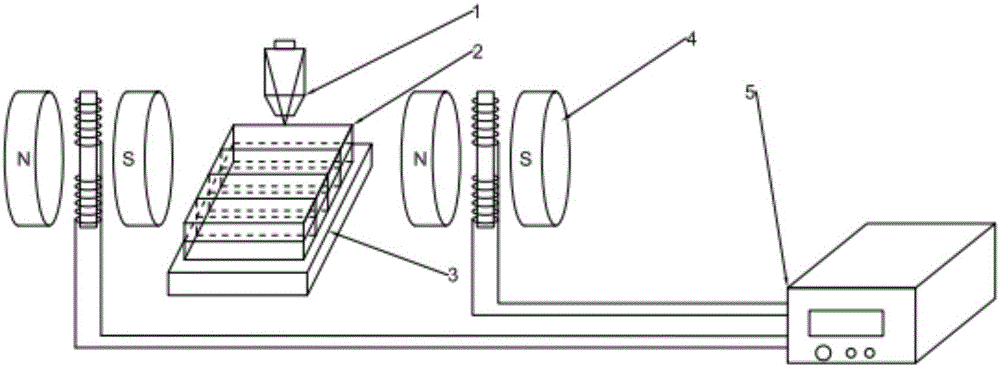

[0019] Using Nd:YAG solid-state continuous laser, constant strong magnetic field and pulsed magnetic field device to treat Al 2 o 3 and ZrO 2 The powder is subjected to laser near-net forming, and the specific forming steps are as follows:

[0020] A. The experimental substrate 3 is polished with sandpaper, washed with acetone, ethanol, and deionized water in sequence, and dried, and Al with a diameter of 40-90 μm is selected. 2 o 3 and ZrO 2 Powder, put the powder in an electric blast drying oven at 100°C for 4 hours, dry the ceramic powder and put it into a stable and strong magnetic field working platform and turn on the magnetic field generator, and magnetize for 60 minutes within a magnetic field strength of 15T. , and then put the ceramic powder into the powder cylinder of the powder feeder;

[0021] B. Turn on the pulsed magnetic field generator 5, set the pulsed magnetic field intensity to 15T, the duty cycle to 50%, the frequency to 15Hz, and the magnetic field d...

Embodiment 2

[0025] Using Nd:YAG solid-state continuous laser, constant strong magnetic field and pulsed magnetic field device to treat Al 2 o 3 Laser near-net forming with SiC powder, the specific forming steps are as follows:

[0026] A. The experimental substrate 3 is polished with sandpaper, washed with acetone, ethanol, and deionized water in sequence, and dried, and Al with a diameter of 40-90 μm is selected. 2 o 3 and SiC powder, put the powder in an electric blast drying oven and dry it at 100°C for 4 hours, dry the ceramic powder and put it into a working platform with a constant strong magnetic field and turn on the magnetic field generator, and magnetize it for 100 minutes in the range of a magnetic field strength of 18T . , and then put the ceramic powder into the powder cylinder of the powder feeder;

[0027] B. Turn on the pulsed magnetic field generator 5, set the pulsed magnetic field intensity to 18T, the duty cycle to 40%, the frequency to be 12Hz, and the magnetic fiel...

Embodiment 3

[0031] Using Nd:YAG solid-state continuous laser, constant strong magnetic field and pulsed magnetic field device to treat Al 2 o 3 and Si 3 N 4 The powder is subjected to laser near-net forming, and the specific forming steps are as follows:

[0032] A. The experimental substrate 3 is polished with sandpaper, washed with acetone, ethanol, and deionized water in sequence, and dried, and Al with a diameter of 40-90 μm is selected. 2 o 3 and Si 3 N 4 Powder, put the powder in an electric blast drying oven at 100°C to dry for 4 hours, dry the ceramic powder and put it into a working platform with a constant strong magnetic field and turn on the magnetic field generator to magnetize for 60 minutes within a magnetic field strength of 20T. , and then put the ceramic powder into the powder cylinder of the powder feeder;

[0033] B. Turn on the pulsed magnetic field generator 5, set the pulsed magnetic field intensity to 20T, the duty cycle to 60%, the frequency to be 10Hz, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com