Method for controlling grain boundary characteristics of austenitic stainless steel

A technology of austenitic stainless steel and grain boundary, which is applied in the field of controlling the surface structure of austenitic stainless steel to achieve the effect of improving the resistance to intergranular corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

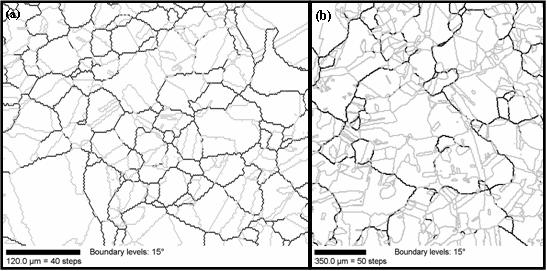

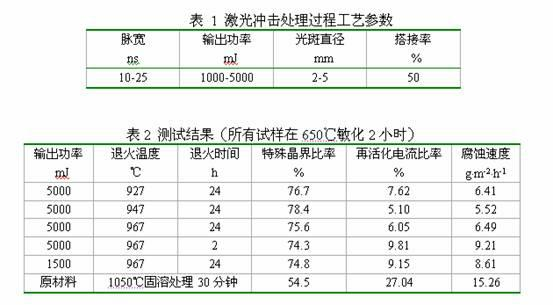

[0013] A Q-switched neodymium glass laser was used to perform surface impact treatment on austenitic stainless steel. The specific process parameters are shown in Table 1. Subsequently, the impacted sample was annealed at 927°C, 947°C and 967°C for 24 hours respectively, so that the ratio of low-energy CSL (heavy site lattice) grain boundaries (Σ≤29) in the treated layer can reach more than 74%. , the specific test results are shown in Table 2.

[0014]

Embodiment 2

[0016] At room temperature in 0.5 M H 2 SO 4 Electrochemical corrosion experiments were carried out on the treated materials in +0.01M KSCN solution. The reactivation current ratio varied with the sensitization temperature and time. The reactivation current ratio measured at 650°C for 2 hours is listed in Table 2.

Embodiment 3

[0018] Table 2 lists the corrosion rate of the treated material after being sensitized at 650°C for 2 hours and corroded in boiling sulfuric acid-ferric sulfate solution for 72 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com