Intergranular corrosion resistant Ni-saving type duplex stainless steel and preparation method thereof

A technology of duplex stainless steel and intergranular corrosion, applied in the field of steel alloy materials, can solve the problems of no intergranular corrosion sensitivity data, no mention of the intergranular corrosion resistance of stainless steel, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

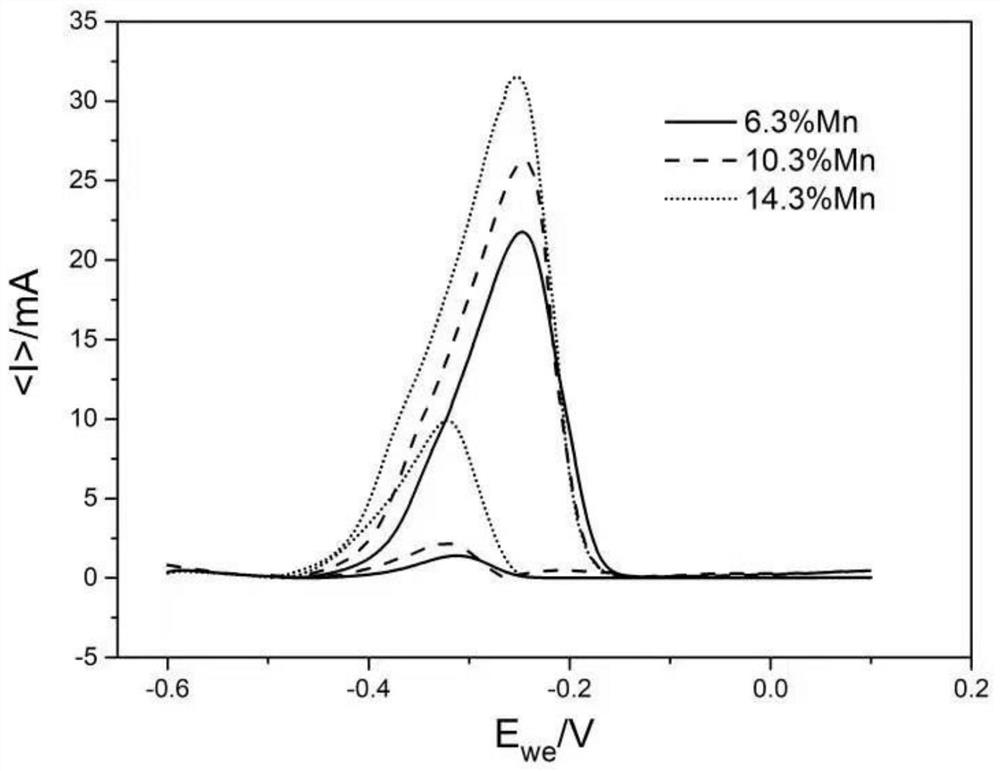

[0035] In this embodiment, there are three types of Ni-saving duplex stainless steel components and mass percentages:

[0036] 1#C: 0.04%, Si: 0.22%, Mn: 6.3%, Cr: 23.34%, Ni: 2.20%, Mo: 1.41%, Cu: 0.14%, N: 0.26%, P: 0.008%, S: 0.004 %, the balance is Fe and unavoidable impurities;

[0037] 2#C: 0.04%, Si: 0.23%, Mn: 10.3%, Cr: 23.39%, Ni: 2.20%, Mo: 1.35%, Cu: 0.14%, N: 0.28%, P: 0.006%, S: 0.004 %, the balance is Fe and unavoidable impurities;

[0038] 3#C: 0.04%, Si: 0.25%, Mn: 14.3%, Cr: 23.40%, Ni: 2.20%, Mo: 1.30%, Cu: 0.14%, N: 0.28%, P: 0.006%, S: 0.003 %, the balance is Fe and unavoidable impurities;

[0039]The above three kinds of Ni-saving duplex stainless steel 1#, 2# and 3# are prepared according to the following steps:

[0040] (1) adopt 50kg vacuum melting furnace to refine different manganese content 23% Cr section Ni type duplex stainless steel billet;

[0041] (2) Perform pre-forging treatment on the cast slab, control the initial forging temperature a...

Embodiment 2

[0048] In this example, the composition and mass percentage of Ni-saving duplex stainless steel are: C: 0.04%, Si: 0.22%, Mn: 6.3%, Cr: 23.34%, Ni: 2.20%, Mo: 1.41%, Cu: 0.14 %, N: 0.26%, P: 0.008%, S: 0.004%, the balance is Fe and unavoidable impurities;

[0049] The above-mentioned Ni-saving type duplex stainless steel is prepared according to the following steps:

[0050] (1) Adopt 50kg vacuum melting furnace to refine 6.3% Mn content 23% Cr section Ni type duplex stainless steel billet;

[0051] (2) Perform pre-forging treatment on the cast slab, control the initial forging temperature at 1050°C to 1150°C, control the final forging temperature at 1000°C to 1050°C, forging ratio of 2 to 4, and quickly cool after forging;

[0052] (3) Pre-rolling the plate obtained by forging, the starting rolling temperature is controlled at 1100°C to 1200°C, the final rolling temperature is controlled at 1000°C to 1050°C, and the plate is obtained by water quenching;

[0053] (4) The pla...

Embodiment 3

[0059] In this embodiment, the composition and mass percentage of Ni-saving duplex stainless steel are: C: 0.04%, Si: 0.23%, Mn: 10.3%, Cr: 23.39%, Ni: 2.20%, Mo: 1.35%, Cu: 0.14 %, N: 0.28%, P: 0.006%, S: 0.004%, the balance is Fe and unavoidable impurities;

[0060] (1) Adopt 50kg vacuum melting furnace to refine 10.3% Mn content 23% Cr section Ni type duplex stainless steel billet;

[0061] (2) Perform pre-forging treatment on the cast slab, control the initial forging temperature at 1050°C to 1150°C, control the final forging temperature at 1000°C to 1050°C, forging ratio of 2 to 4, and quickly cool after forging;

[0062] (3) Pre-rolling the plate obtained by forging, the starting rolling temperature is controlled at 1100°C to 1200°C, the final rolling temperature is controlled at 1000°C to 1050°C, and the plate is obtained by water quenching;

[0063] (4) The plate obtained after rolling and water cooling is processed into φ8mm×15mm, and solution treatment is carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com