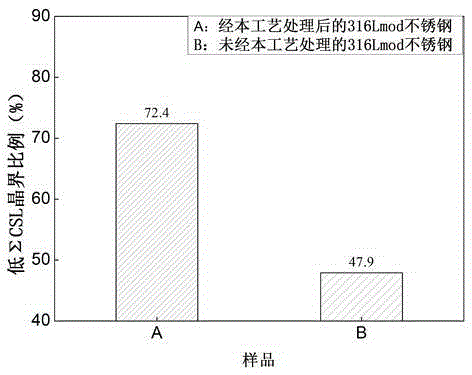

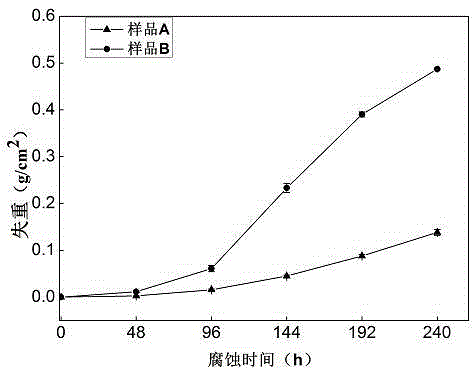

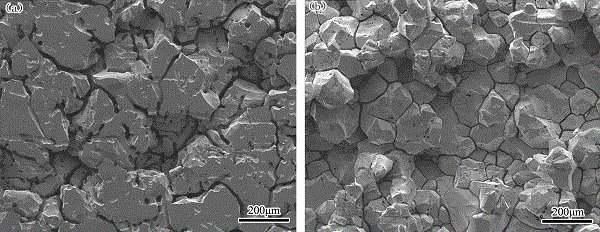

Grain boundary engineering technique for improving corrosion resistance of 316Lmod stainless steel

An engineering process, stainless steel technology, applied in the field of grain boundary engineering process of stainless steel materials, can solve the problems of long-time annealing, unfavorable cost control, etc., achieve the improvement of fatigue resistance, improve intergranular corrosion resistance, and increase the proportion of grain boundaries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are described in detail as follows:

[0022] In this embodiment, the modified 316L stainless steel, which is specially used to manufacture urea-grade stainless steel for urea production equipment, is used, that is, the grain boundary engineering process of implementing corrosion resistance with 316Lmod stainless steel. A kind of grain boundary engineering process method of present embodiment improves the corrosion resistance of 316Lmod stainless steel, comprises the steps:

[0023] a. Keep the 316Lmod stainless steel plate at 1100°C for 30 minutes, then water-cool;

[0024] b. at room temperature, the 316Lmod stainless steel after the heat treatment in the step a is processed and deformed again, and the amount of deformation controlled is 5%;

[0025] c. Then anneal the 316Lmod stainless steel deformed in the step b. During annealing, it is kept at 1075° C. for 30 minutes, and then water-cooled to obtain 316Lmod stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com