Dual-phase anti-corrosion stainless steel and corrosion resistance optimizing treatment process thereof

A duplex stainless steel, corrosion-resistant technology, applied in the field of metallurgy, can solve the problems of insufficient proportion of phase boundary, limited effect of refining structure and improving strip morphology, and the inability to eradicate the structure and morphology of duplex stainless steel strips, etc. Achieve the effects of improving corrosion resistance, improving intergranular corrosion resistance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Optimizing the hot-rolled duplex stainless steel plate, the alloy composition is (mass ratio, wt%): 0.017C, 22.16Cr, 5.28Ni, 0.52Si, 1.11Mn, 0.151N, 0.026P, 0.0016S, 3.09Mo , the initial sample grain size was 30 μm.

[0033] In the first step, the hot-rolled sheet is heated to the solution temperature at a heating rate of 22° C. / min, then solid solutioned at 1250° C. for 20 minutes, and cooled to room temperature with water.

[0034] In the second step, the alloy plate after solid solution is subjected to cross rolling with ε=3.

[0035] In the third step, the rolled alloy plate is annealed. The temperature rise rate of the vacuum annealing furnace is 27°C / min.

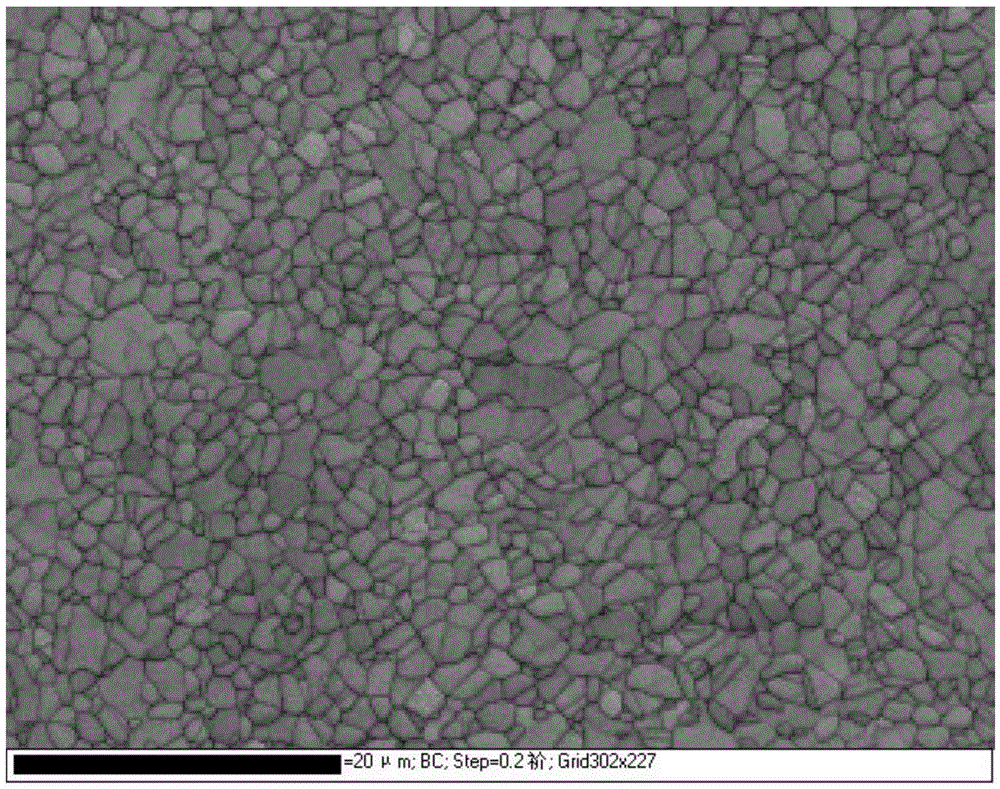

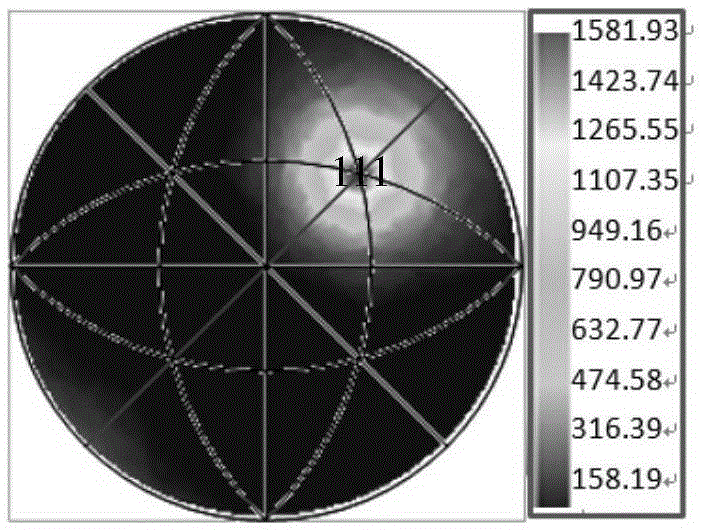

[0036] The microstructure of the duplex stainless steel plate after optimization treatment is as follows figure 1 As shown, the average grain size is 2 μm. The proportion of low-energy grain boundaries after optimization is 83%.

Embodiment 2

[0038] The hot-rolled duplex stainless steel plate is optimized, and its composition is (wt%): 0.016C, 24.1Cr, 4.10Ni, 0.55Si, 1.10Mn, 0.2N, 0.025P, 0.002S, 3.0Mo, grain Initial sample with a size of 32 μm.

[0039] In the first step, the hot-rolled sheet is heated up to the solution temperature at a heating rate of 20°C / min, then solidified at 1200°C for 16 minutes, and cooled to room temperature with water.

[0040] In the second step, the alloy plate after solid solution is subjected to unidirectional rolling with ε=2.

[0041] In the third step, the rolled alloy plate is annealed. The temperature rise rate of the vacuum annealing furnace is 25° C. / min, and the temperature is kept at 1025° C. for 10 minutes, and then water-cooled.

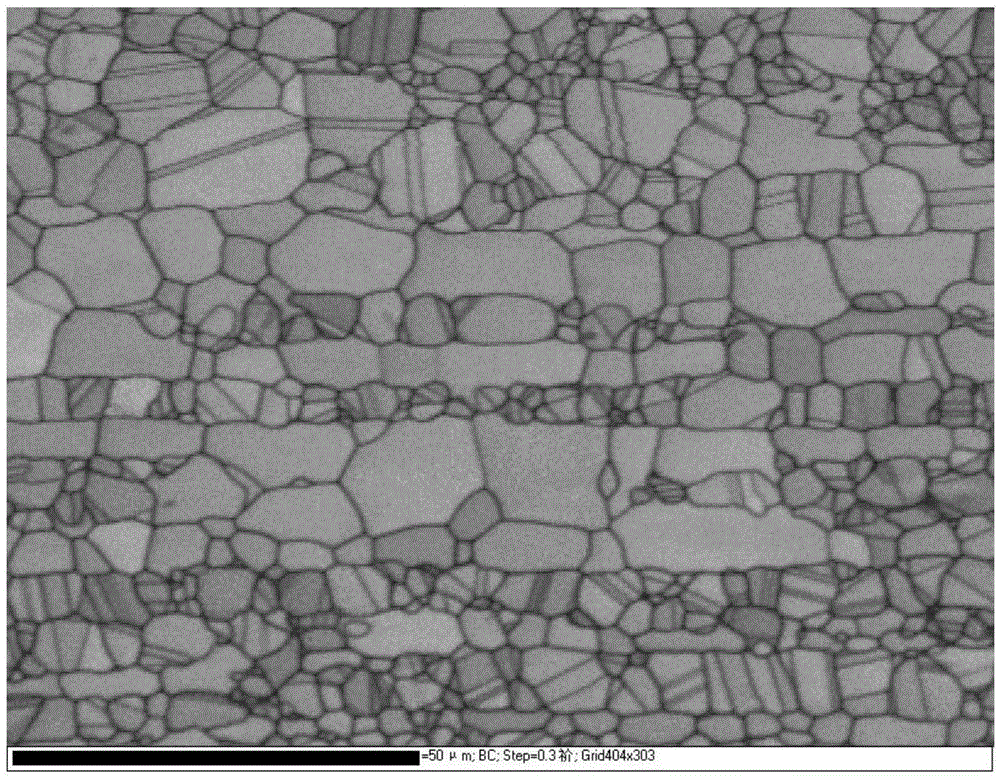

[0042] The average grain size of the two phases of the stainless steel plate obtained after optimization treatment is about 3 μm, and the proportion of the low-energy interface grain boundary is 78%. Most of the interfaces of the corrosion mor...

Embodiment 3

[0044] Optimizing the hot-rolled duplex stainless steel plate, the alloy composition is (mass ratio, wt%): 0.020C, 22.1Cr, 5.3Ni, 0.50Si, 1.20Mn, 0.15N, 0.026P, 0.001S, 4.1Mo , the initial sample grain size was 30 μm.

[0045] In the first step, the hot-rolled sheet is heated to the solution temperature at a heating rate of 25° C. / min, then solid solutioned at 1300° C. for 30 minutes, and cooled to room temperature with water.

[0046] In the second step, the alloy plate after solid solution is subjected to cross-rolling of ε=3, and the rolling deformation of each pass is ε=0.2. After each pass of rolling, the plate is rotated 90 degrees and then cross-rolled, and so forth, After 15 passes, the desired amount of deformation is achieved.

[0047] In the third step, the rolled alloy plate is annealed. The temperature rise rate of the vacuum annealing furnace is 30° C. / min, and the temperature is kept at 1050° C. for 5 minutes, and then water-cooled.

[0048] The average grain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com