High-nitrogen nickel-free austenitic stainless steel intergranular-corrosion-prevention processing technology

A technology of austenitic stainless steel and treatment process, which is applied in the field of treatment process to improve the anti-intergranular corrosion ability of high-nitrogen nickel-free austenitic stainless steel to achieve the effect of improving corrosion fatigue performance

Inactive Publication Date: 2015-12-23

NORTHEASTERN UNIV LIAONING

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the research on improving the intergranular corrosion performance of high-nitrogen nickel-free austenitic stainless steel with GBE has not been reported yet.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0043] Example 2

Embodiment 2

[0045] Example 3

Embodiment 3

[0047] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

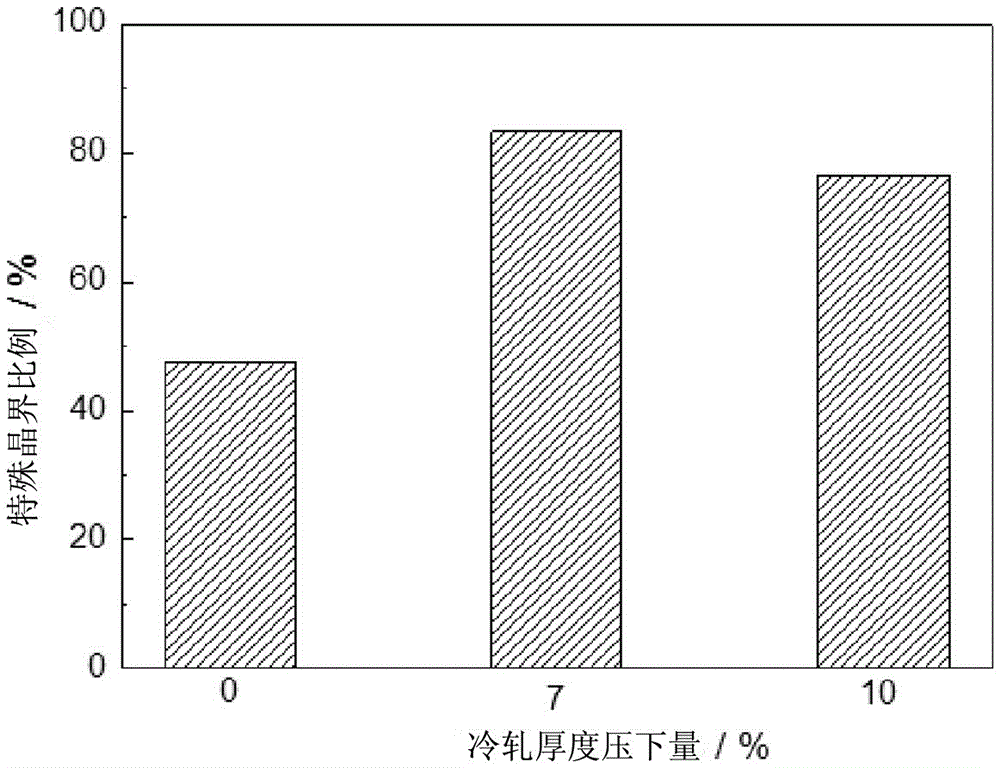

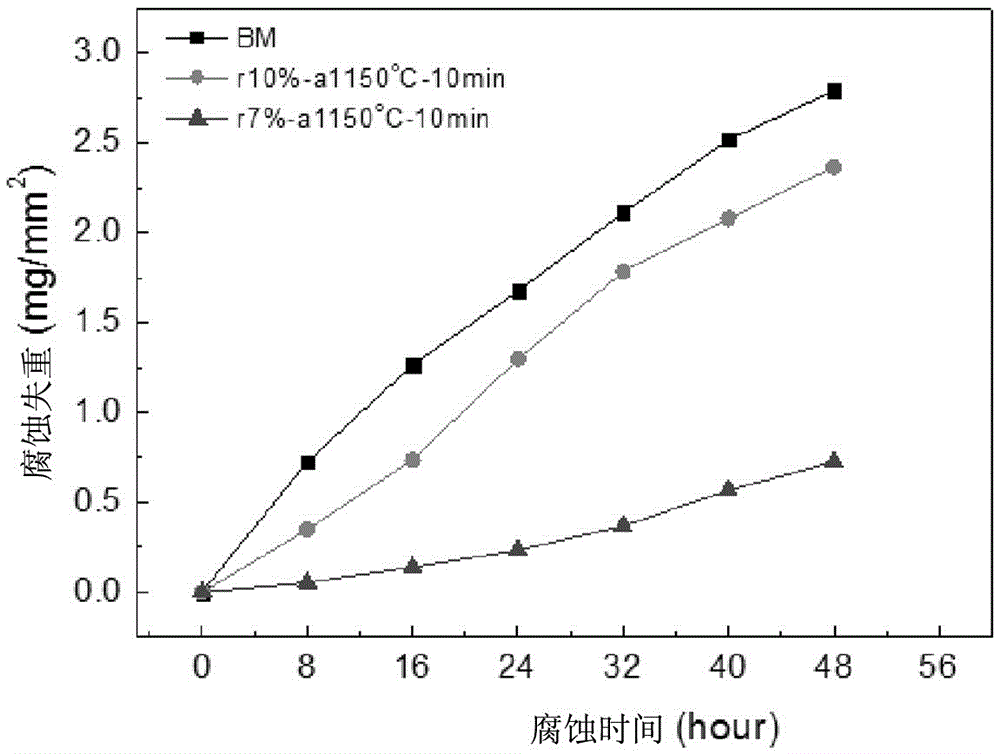

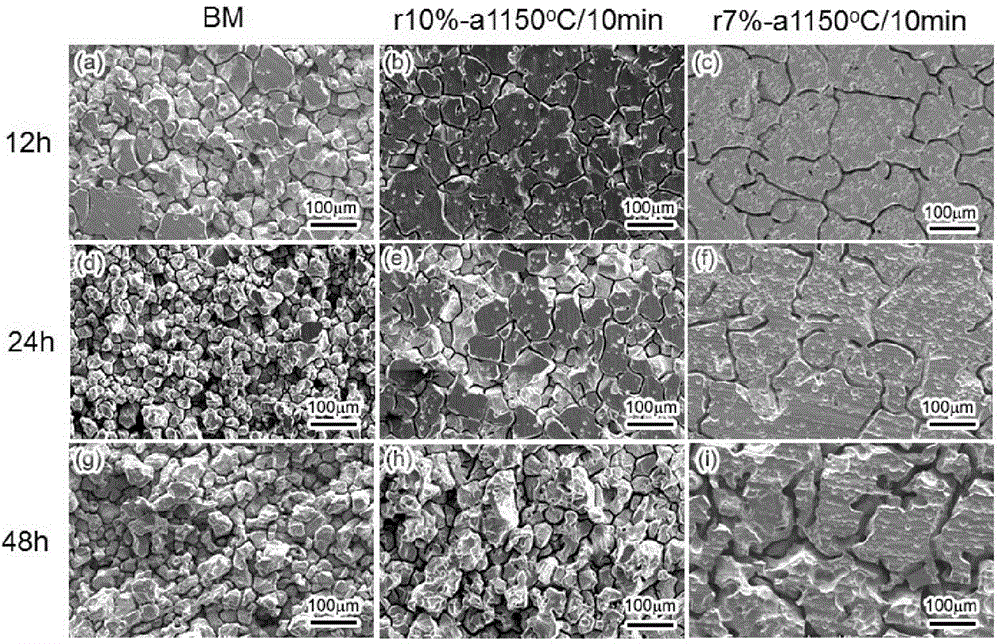

The invention relates to a high-nitrogen nickel-free austenitic stainless steel intergranular-corrosion-prevention processing technology. Solution treatment is firstly carried out on materials; and then cold rolling deformation and recrystallization annealing technological treatment is carried to enable the proportion of the special grain boundary in high-nitrogen nickel-free austenitic stainless steel to be improved, and therefore the aim of improving the decay resistance of the materials is accordingly achieved. The high-nitrogen nickel-free austenitic stainless steel intergranular-corrosion-prevention performance can be obviously improved through technological treatment.

Description

technical field [0001] The invention belongs to the field of performance optimization of stainless steel, in particular to a treatment process for improving the anti-intergranular corrosion ability of high-nitrogen nickel-free austenitic stainless steel. Background technique [0002] In recent years, the contradiction between the ever-increasing demand for stainless steel and the limited nickel resources has become increasingly serious, resulting in the continuous rise in the price of nickel-containing stainless steel, especially the price of nickel-containing austenitic stainless steel. In addition, human organs are sensitive to nickel-containing stainless steel Bioengineering materials are allergic (Ni>0.2%), and the incidence of human skin allergies caused by this is constantly increasing. Therefore, people have focused their attention on resource-saving stainless steel - high nitrogen nickel-free austenitic stainless steel. The introduction of a sufficient amount of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D8/00C21D1/18C21D1/26C22C38/38

Inventor 石锋李小武祁阳刘春明贾楠田鹏程高若涵

Owner NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com