Simple aluminum fluoride charging hopper

A technology of aluminum fluoride and hoppers, which is applied in the field of simple aluminum fluoride hoppers, can solve the problems of complex plant configuration, inconvenient opening and closing of its feeding valves, waste of funds, etc., and achieves easy maintenance, compact structure, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

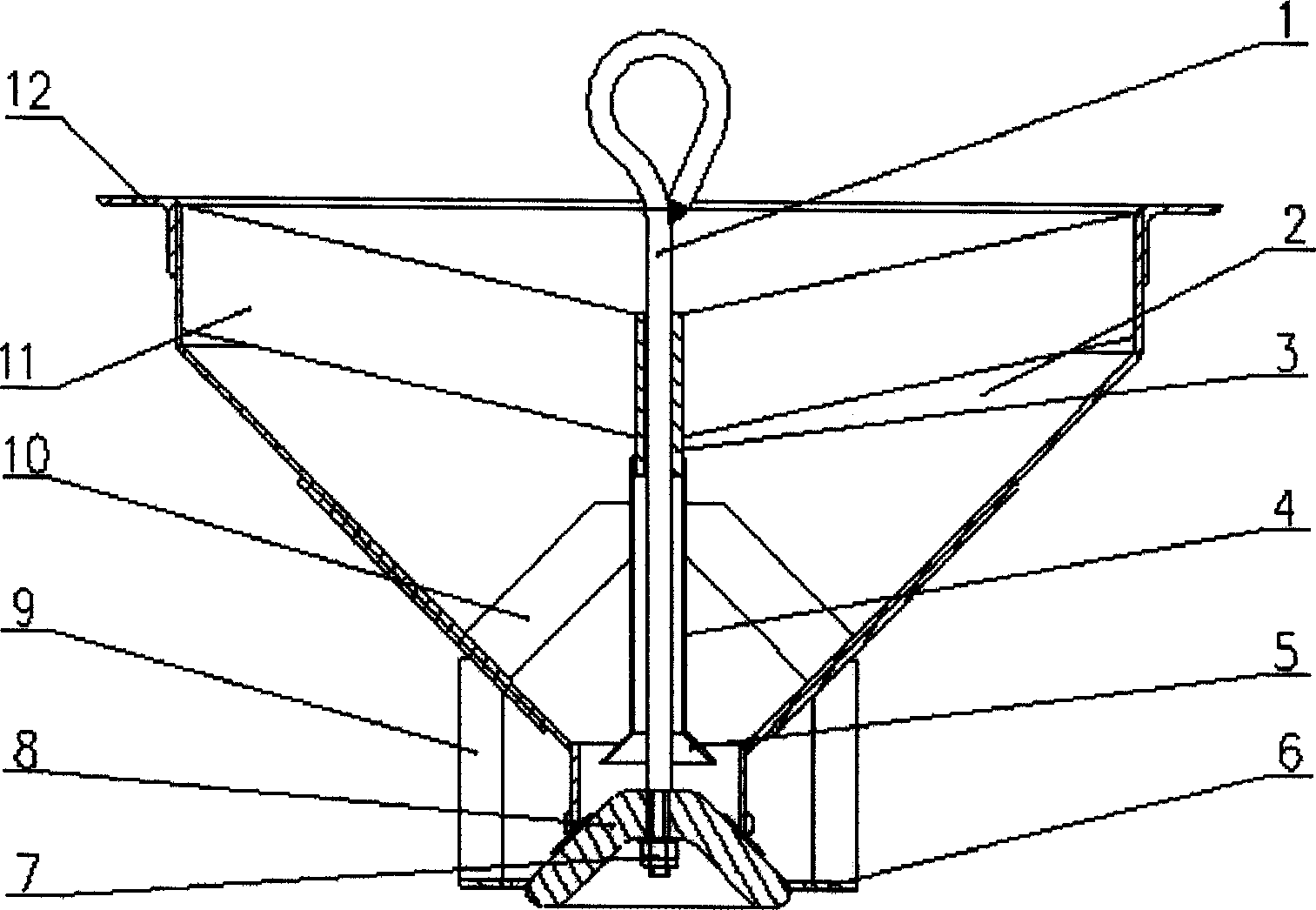

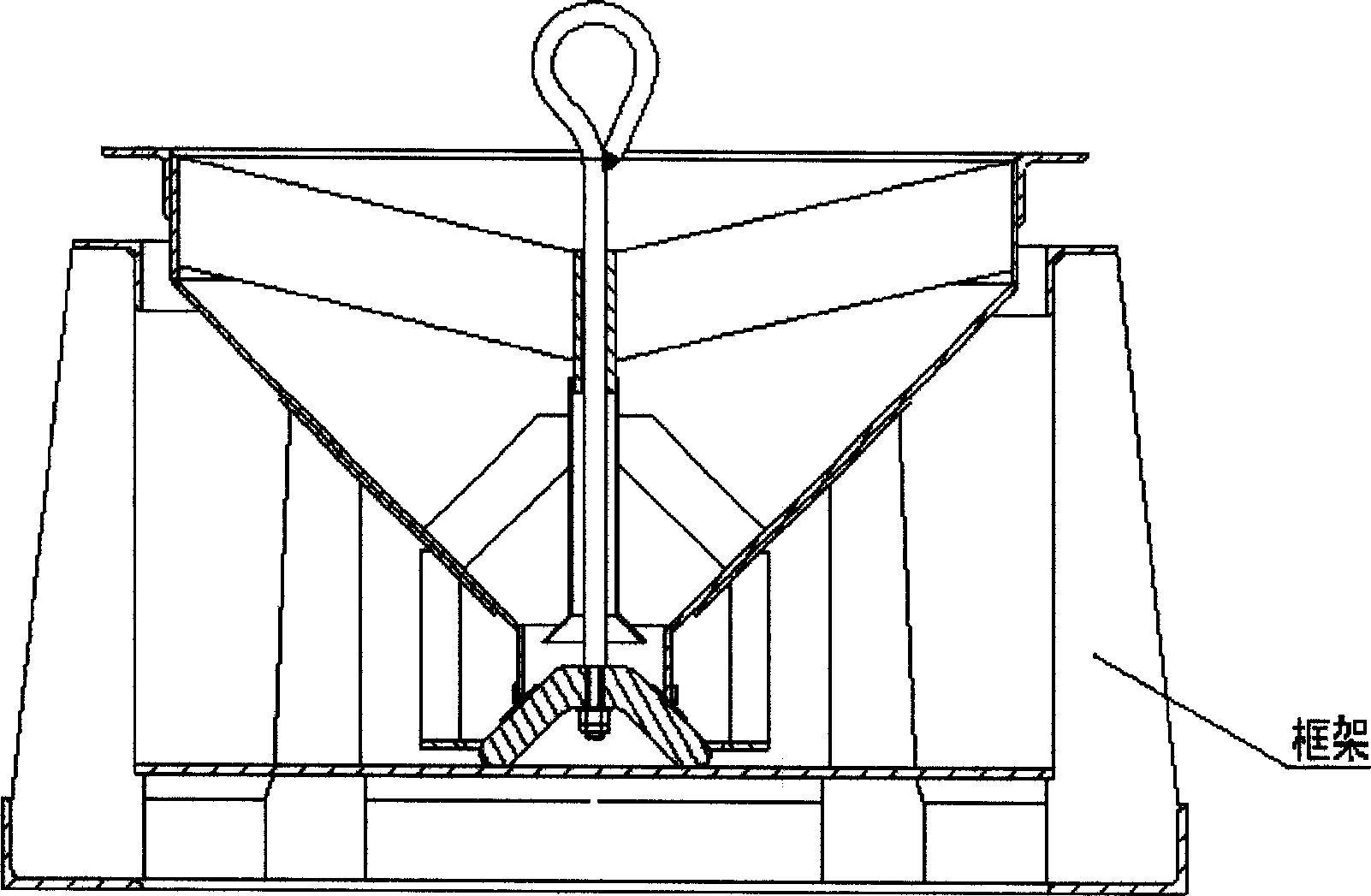

[0013] Embodiment of the present invention: make a conical hopper 2, and weld the support plate 9 at its lower part to connect with the annular base 6, and weld the reinforcing ring 12 at the upper part; make the pull rod 1, whose upper end is bent into a ring-shaped hook, and the end is welded to the neck Firm, the lower end is made into thread; make guide sleeve 3, sleeve 4, bell mouth 5, and weld them to form guide device; make sealing bottom cover 8 and other parts; use rib plate 11 and guide sleeve 3 and conical hopper 2 Welding, using the rib plate 10 to weld the sleeve 4 and the conical hopper 2; pass the threaded end of the pull rod 1 through the guide device and the sealing bottom cover 8, and fix it at the lower groove of the sealing bottom cover 8 with the nut 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com