Preparation method of nanometer aluminum fluoride-based catalyst

A technology of aluminum fluoride and catalyst, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex process, amorphous structure of aluminum fluoride, high energy consumption, etc., and meet the preparation conditions Mild, catalytic reaction, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Preparation of large specific surface area, nano aluminum fluoride

[0049] Dissolve 0.5M aluminum source in 50mL organic solvent, reflux at 20-80°C for 6 hours, then slowly add the fluorinated reagent aqueous solution to the above solution with stirring, and the dropping time is 1 hour. Stir for another 6 hours to obtain a liquid sol; then statically age at 60-90°C for more than 24 hours to obtain a solid gel; then dry at 100-160°C for more than 24 hours, and finally roast at 350-450°C for more than 4 hours to obtain a high-temperature High specific surface area, nanocrystalline aluminum fluoride. The texture properties of aluminum fluoride prepared under different aluminum sources, organic solvents, fluorinating reagents, and calcination temperatures are shown in Table 1.

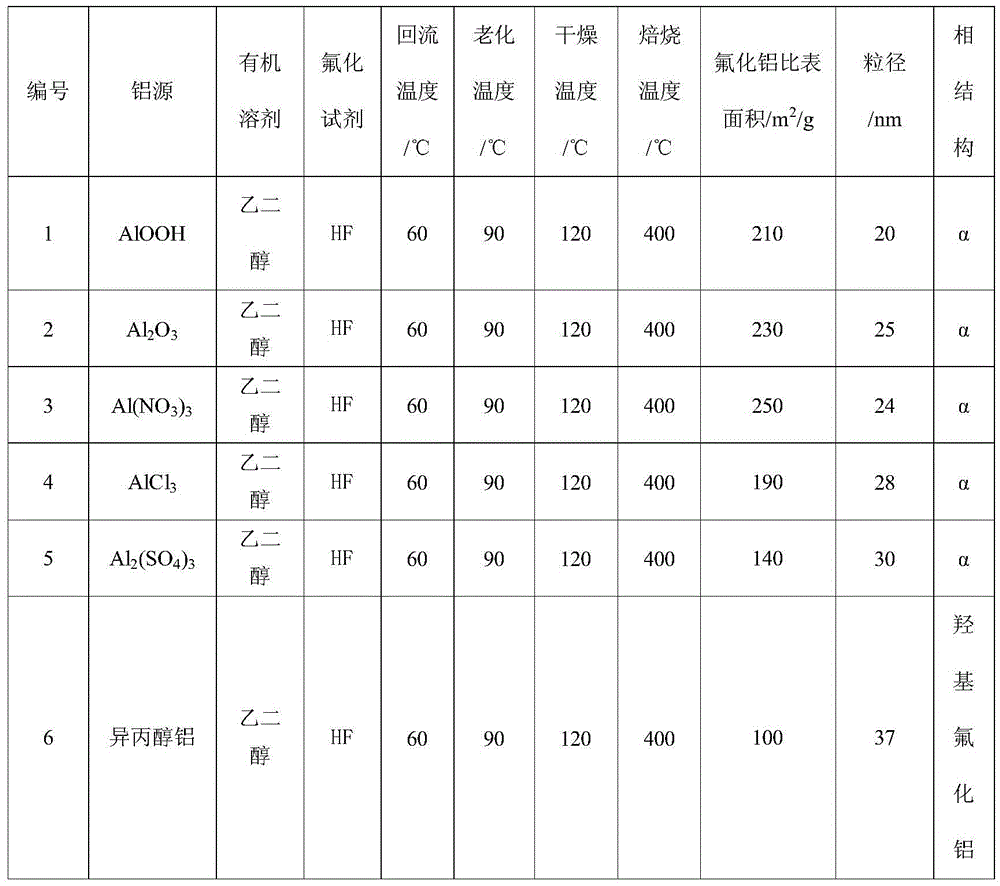

[0050] The physical and chemical property results of aluminum fluoride in Example 1 of table 1

[0051]

[0052]

Embodiment 2

[0053] Embodiment 2: Preparation of large specific surface area, nano aluminum fluoride

[0054] Dissolve 0.5M aluminum nitrate in 50mL of ethylene glycol, reflux at 60°C for 6 hours, then slowly add HF aqueous solution to the above solution dropwise with stirring, the dropping time is 1 hour, and then stir for 6 hours after the dropping is completed , to obtain a liquid sol; then aged at 90°C for more than 24 hours to obtain a solid gel; then dried at 150°C for more than 24 hours, and finally roasted at 400°C for more than 4 hours to obtain a nanocrystalline fluoride with a large specific surface area at high temperature Aluminum based catalysts. The textures of aluminum fluoride-based catalysts prepared with different amounts of fluorinating reagents are shown in Table 2.

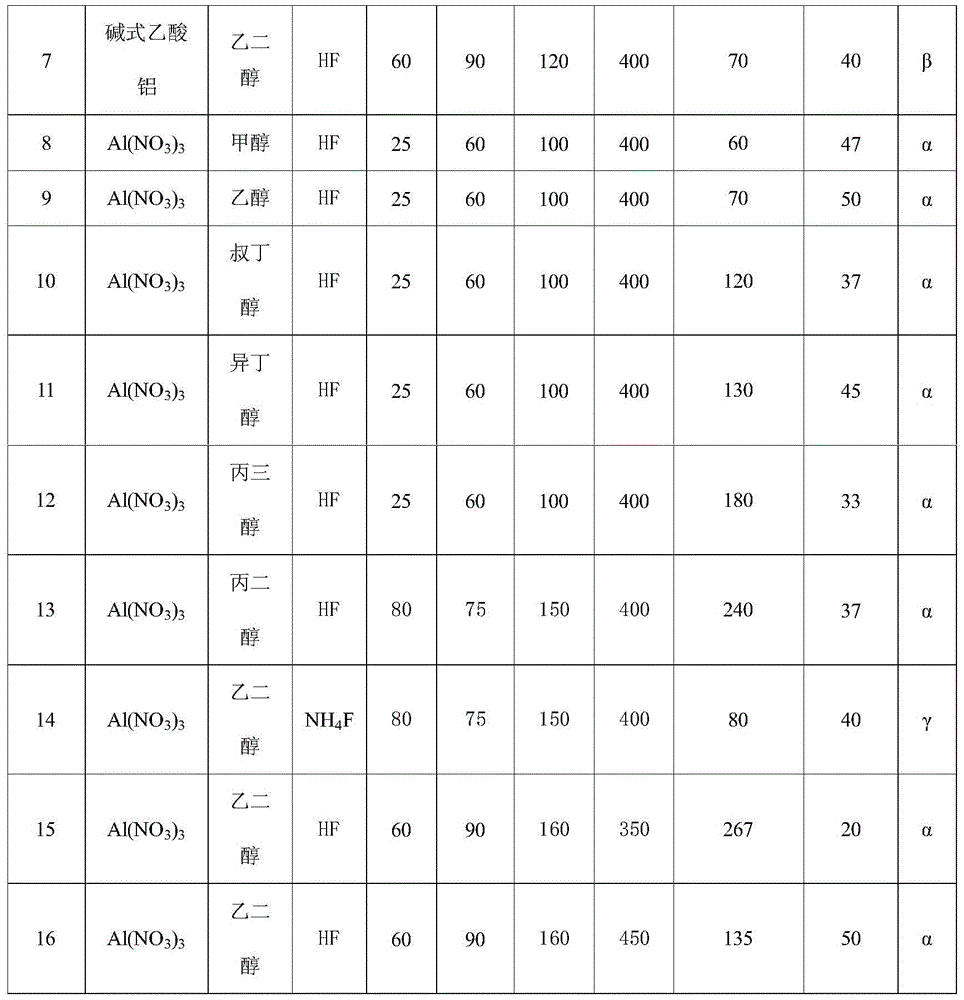

[0055] The physical and chemical property results of aluminum fluoride in embodiment 2 of table 2

[0056]

Embodiment 3

[0057] Example 3: Preparation of large specific surface area, nano-aluminum fluoride-based catalyst

[0058] Dissolve 0.5M aluminum nitrate and doping components in 50mL of ethylene glycol, and reflux at 60°C for 6h with stirring, then slowly add HF aqueous solution into the above solution dropwise with stirring for 1h, dropwise Stir for 6 hours after completion to obtain a liquid sol; then statically age at 90°C for more than 24 hours to obtain a solid gel; then dry at 150°C for more than 24 hours, and finally roast at 400°C for more than 4 hours to obtain a large specific surface area at high temperature , Nanocrystalline aluminum fluoride-based catalyst. The specific surface areas of aluminum fluoride-based catalysts prepared with different doping components are shown in Table 3.

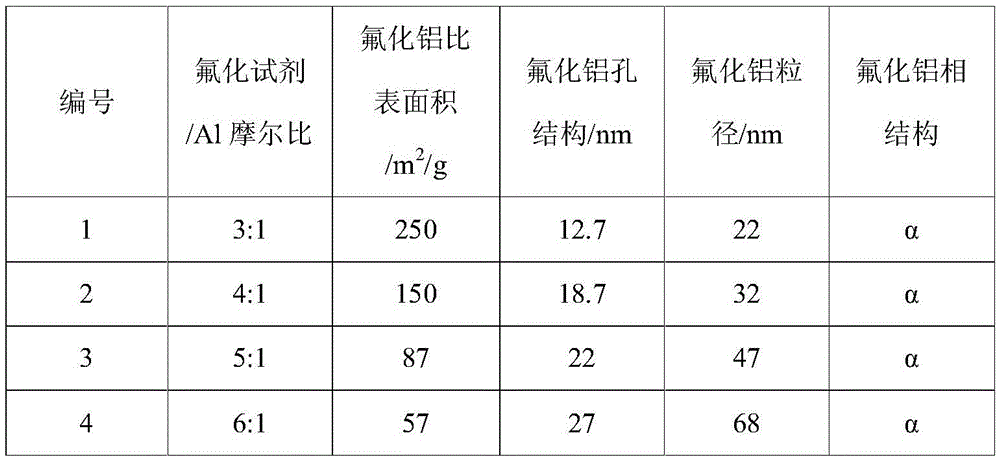

[0059] The physicochemical property result of the aluminum fluoride-based catalyst of table 3 embodiment 3

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com