Thin-film forming apparatus having an automatic cleaning function for cleaning the inside

a technology of thin film forming and inside cleaning, which is applied in the direction of coatings, decorative arts, chemical vapor deposition coatings, etc., can solve the problems of large damage to the reaction chamber, and achieve the effects of reducing non-working cleaning hours, good reproducibility, and enhancing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Structures of Apparatus (In-Situ Plasma Cleaning)

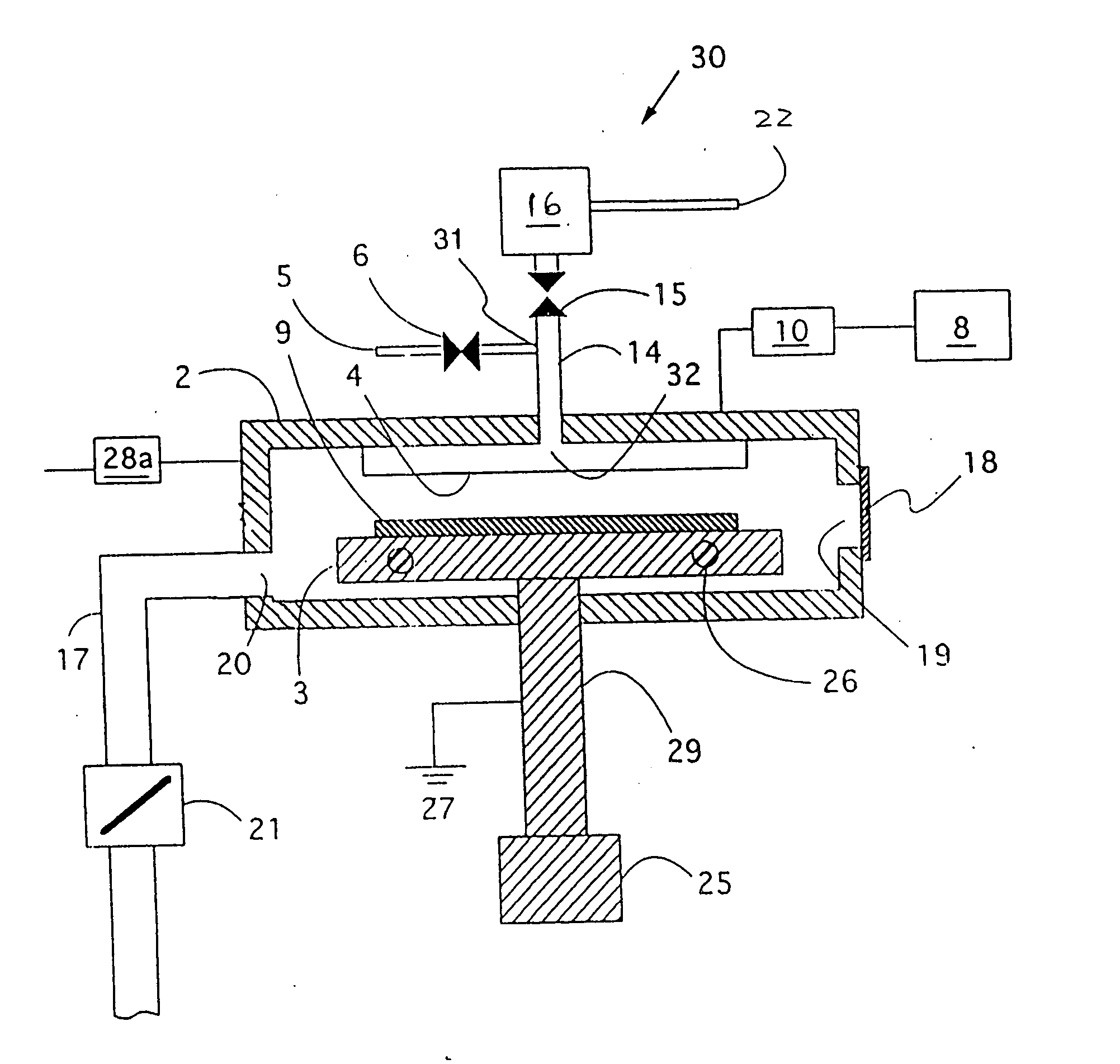

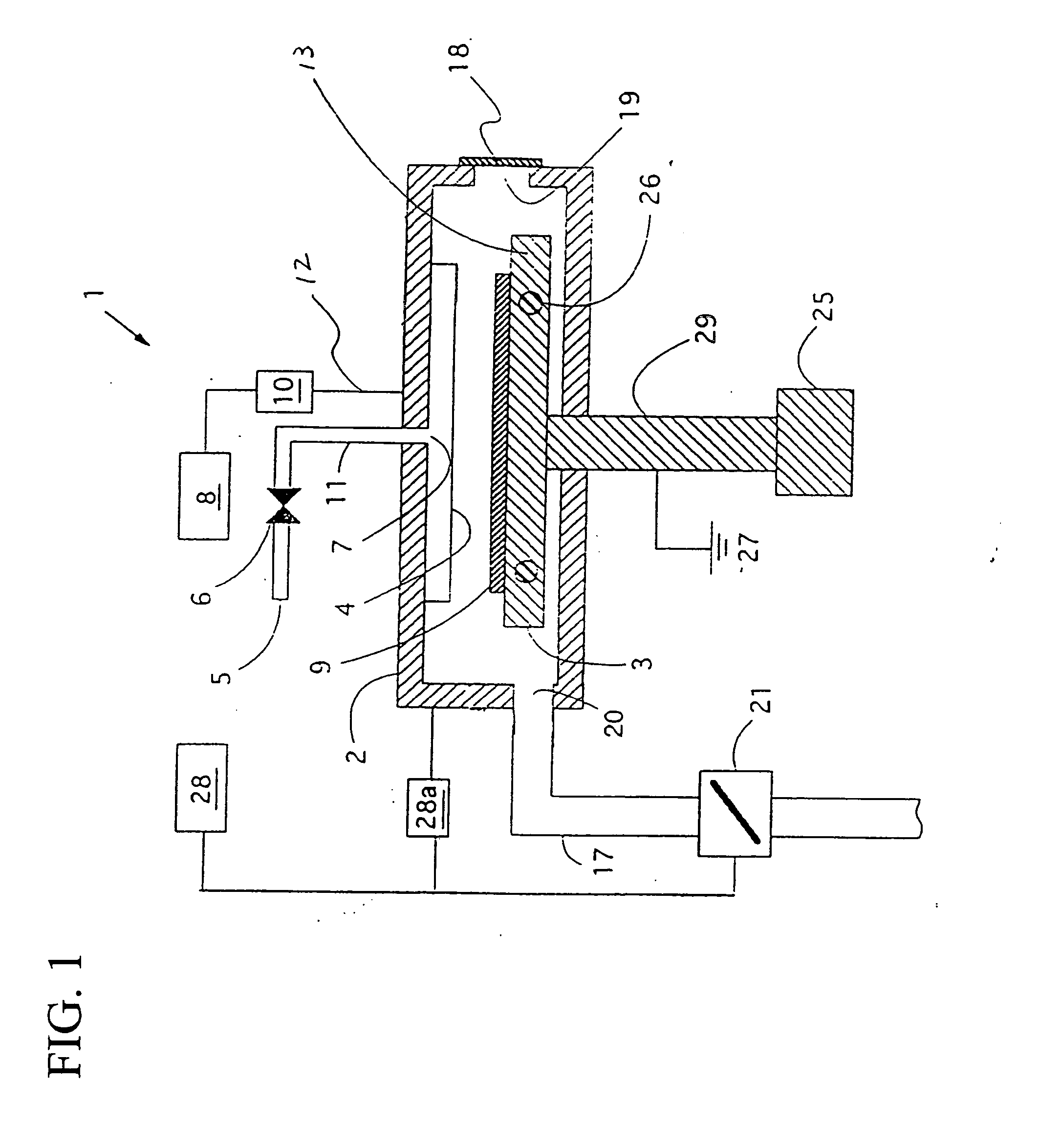

[0047]FIG. 1 shows one example of a thin film-forming and processing apparatus 1 according to the present invention, in which a parallel plate plasma CVD apparatus and an in-situ plasma cleaning apparatus for automatic cleaning are used.

[0048] A workpiece 9 to be processed such as a semiconductor substrate is placed on a ceramic heater 3 to hold the workpiece in a reaction chamber 2. Opposed to the heater 3 is placed a showerhead 4 which provides uniform reaction gas on the workpiece 9. Reaction gas for forming a film on the surface of the workpiece 9 is controlled at a predetermined flow by a mass flow controller (not shown), and enters a duct 5 to a duct 11 through a valve 6. After passing through an aperture 7 of the reaction chamber 2, the gas is provided within the reaction chamber 2 through thousands of tiny holes, with a diameter of less than 1 mm, of the showerhead 4.

[0049] To evacuate the reaction chamber 2, an evacuation...

example 2

Structures of Apparatus (Remote Plasma Cleaning)

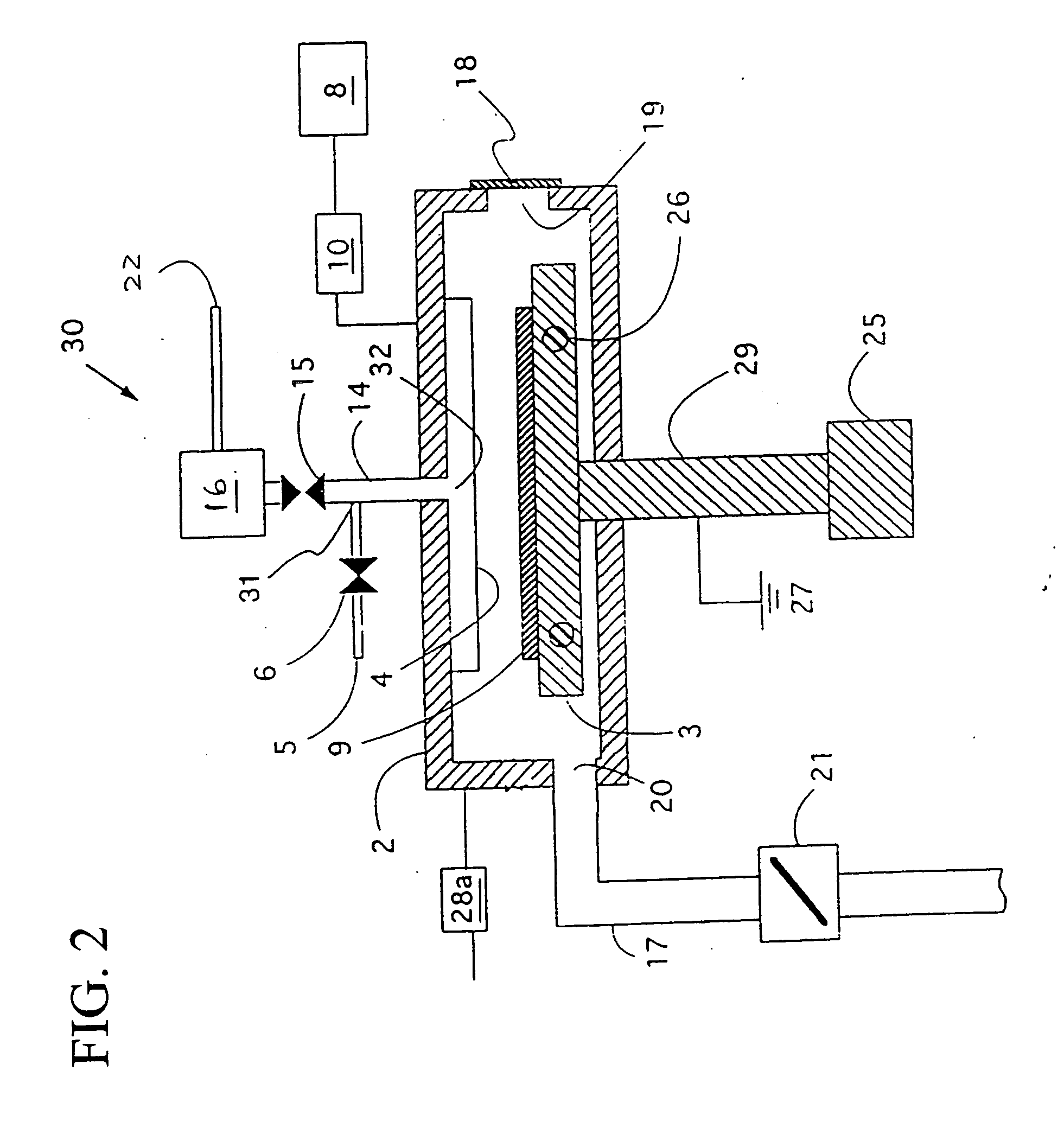

[0059]FIG. 2 illustrates an example of a thin film-forming and processing apparatus 30 having a remote plasma discharge chamber, and is the same as a thin film-forming and processing apparatus of FIG. 1 except for the structure by which unwanted deposits adhering to the inside of the reaction chamber 2 are automatically removed.

[0060] In the upper portion of the reaction chamber 2 are provided a duct 5 and a valve 6 which supply reaction gas to the reaction chamber 2 for thin film-forming and processing. The reaction gas is uniformly supplied onto the surface of a workpiece 9 through a showerhead 4 having thousands of fine holes with a diameter of less than 1 mm via a duct 14 and an opening 32 of the reaction chamber 2. When conducting thin film-forming and processing of the workpiece 9, a valve 15 is closed which valve is provided on the duct 14 connecting a remote plasma discharge chamber 16 to the reaction chamber 2.

Remote Plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com