Preparation method for aluminum-fluoride-coated lithium nickel cobalt manganate positive electrode material

A technology of nickel cobalt lithium manganate and cathode material, which is applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of high rate performance, poor cycle stability, poor safety, etc. The effect of short time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

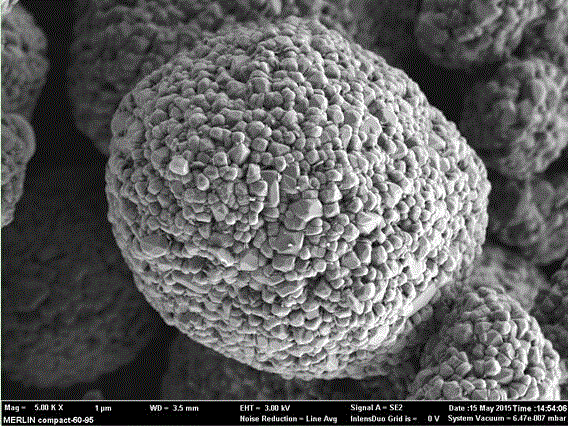

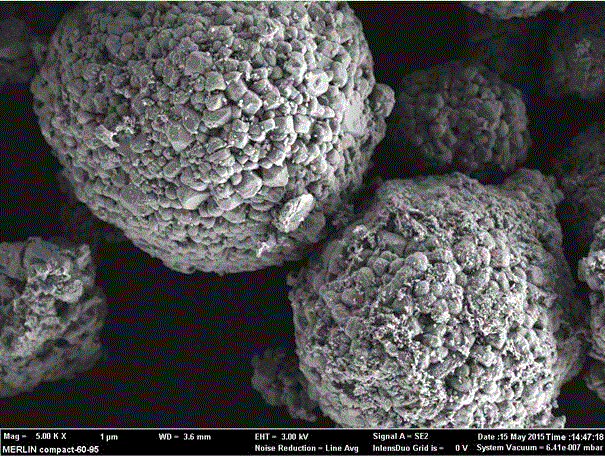

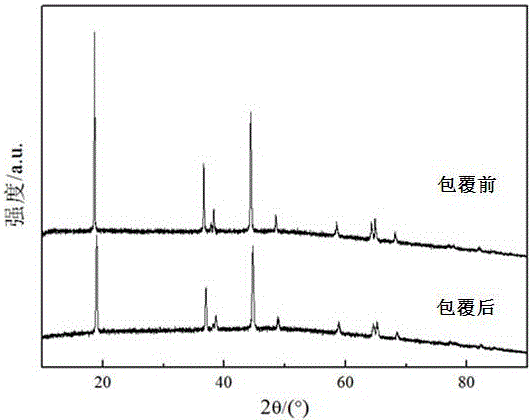

[0021] 0.0161g Al(OH) 3 Add to 60ml deionized water to make aluminum hydroxide suspension, then 20.0gLiNi 0.5 co 0.2 mn 0.3 o 2 Disperse in the solution; slowly add 20ml of ammonium bifluoride solution (containing 0.0365g of ammonium bifluoride) dropwise into the solution under constant stirring in a water bath at 85°C, evaporate until the solution is evaporated to dryness, and stand at 70°C for 2 Hours; Finally, put the product in an oven at 100°C for 1 hour; crush the sample through a 400-mesh sieve to obtain a solid powder; put the solid powder into a tube furnace, and raise the temperature to 500°C at a rate of 1°C / min under a nitrogen atmosphere Calcined for 2 hours and cooled naturally to room temperature to obtain aluminum fluoride-coated nickel-cobalt lithium manganese oxide LiNi 0.5 co 0.2 mn 0.3 o 2 . For comparison of the structure before and after coating, see figure 1 ;Comparison of discharge specific capacity cycle stability of 3.0V-4.3V under 1C rate ...

Embodiment 2

[0023] 0.0161g Al(OH) 3 Add to 60ml deionized water to make aluminum hydroxide suspension, then 20.0gLiNi 0.5 co 0.2 mn 0.3 o 2 Disperse in the solution; slowly add 20ml of ammonium bifluoride solution (containing 0.1095g of ammonium bifluoride) dropwise into the solution under constant stirring in a water bath at 90°C, evaporate until the solution is evaporated to dryness, and stand at 70°C for 2 Hours; Finally, put the product in an oven at 100°C for 1 hour; crush the sample through a 400-mesh sieve to obtain a solid powder; put the solid powder into a tube furnace, and raise the temperature to 650°C at a heating rate of 1°C / min under a nitrogen atmosphere Calcined for 1 hour and cooled naturally to room temperature to obtain aluminum fluoride-coated nickel-cobalt lithium manganese oxide LiNi 0.5 co 0.2 mn 0.3 o 2 .

Embodiment 3

[0025] 0.0161g Al(OH) 3 Add to 60ml deionized water to make aluminum hydroxide suspension, then 20.0gLiNi 0.5 co 0.2 mn 0.3 o 2 Disperse in the solution; slowly add 20ml of ammonium bifluoride solution (containing 0.0730g of ammonium bifluoride) dropwise into the solution under constant stirring in a water bath at 95°C, evaporate until the solution is evaporated to dryness, and stand at 70°C for 2 Hours; Finally, put the product in an oven at 100°C for 1 hour; crush the sample through a 400-mesh sieve to obtain a solid powder; put the solid powder into a tube furnace, and raise the temperature to 650°C at a heating rate of 5°C / min under a nitrogen atmosphere Calcined for 1 hour and cooled naturally to room temperature to obtain aluminum fluoride-coated nickel-cobalt lithium manganese oxide LiNi 0.5 co 0.2 mn 0.3 o 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com