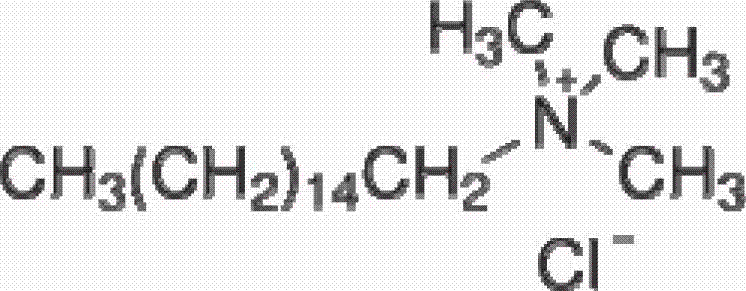

Method for detecting residual disinfecting Cetyltrimethylammonium Chloride used in production process of sodium hyaluronate

A technology of cetyltrimethylammonium chloride and production process, which is applied in the direction of material analysis by observing the influence on chemical indicators, and analysis by chemical reaction of materials, etc., so as to reduce the detection cost and shorten the detection time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

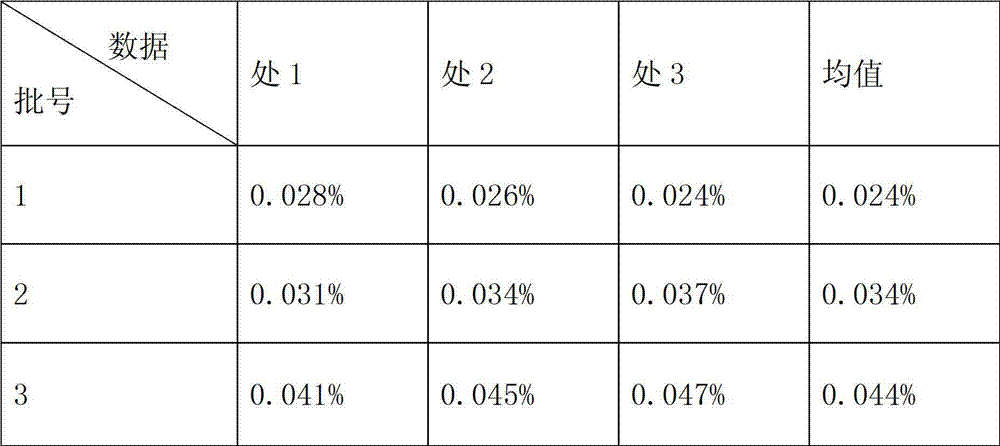

[0030] (1) Weigh cetyltrimethylammonium chloride reference substance, add 2ml of 0.6mol / L hydrochloric acid solution, add water to dissolve to constant volume, and prepare 200μg / ml cetyltrimethylammonium chloride stock solution ; Dilute the cetyltrimethylammonium chloride stock solution to prepare standard solutions of 1 μg / ml, 2 μg / ml, 4 μg / ml, 8 μg / ml, and 10 μg / ml; pipette a certain volume of each standard solution, and set In the test tube, pipette 0.6 mol / L hydrochloric acid solution equal to the volume of the standard solution in the two blank tubes, add 0.5 ml of the modified bismuth potassium iodide test solution to each of the above tubes, mix it in a vortex shaker immediately, and place it at room temperature for 5- 15min, using the blank tube as a control, measure the absorbance at 290nm, and obtain the linear regression equation;

[0031] (2) Preparation of sample solution: Weigh / pippet 5ml of cetyltrimethylammonium chloride sample, add 2ml of 0.6mol / L hydrochloric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com