Preparation of reversible thermo-color material, and preparation and applications of thermo-color solution system thereof

A thermal discoloration and solution technology, applied in the direction of color-changing fluorescent materials, applications, home appliances, etc., to achieve the effect of easy-to-obtain materials, wide application and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

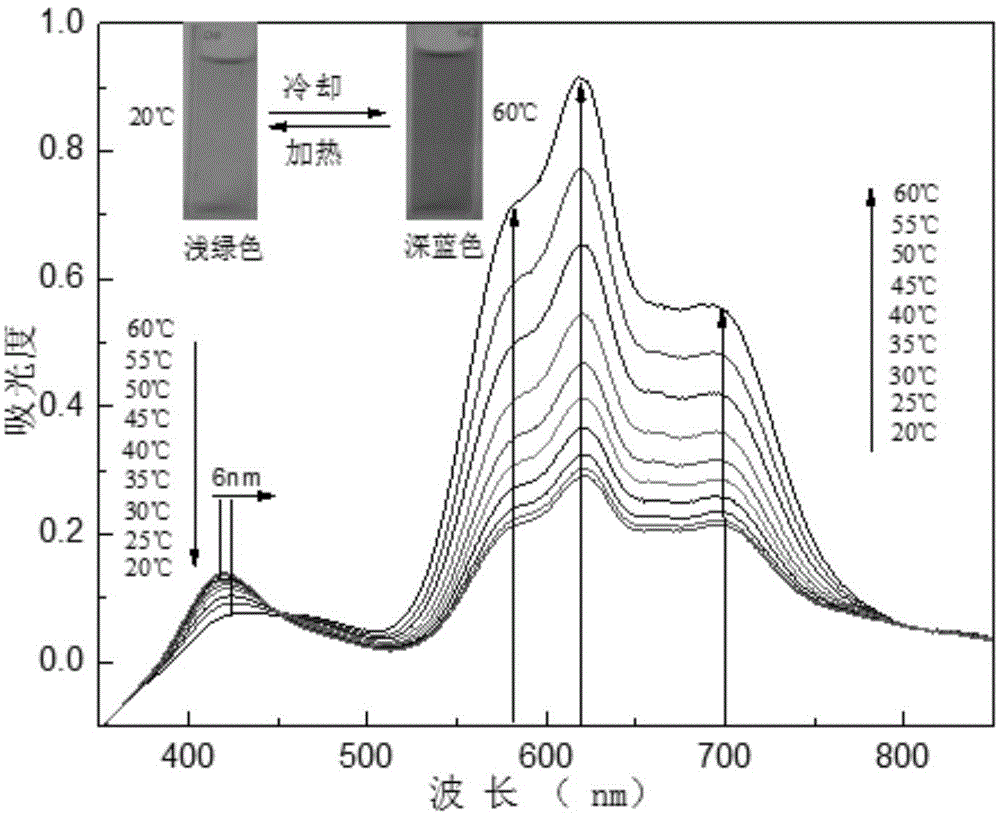

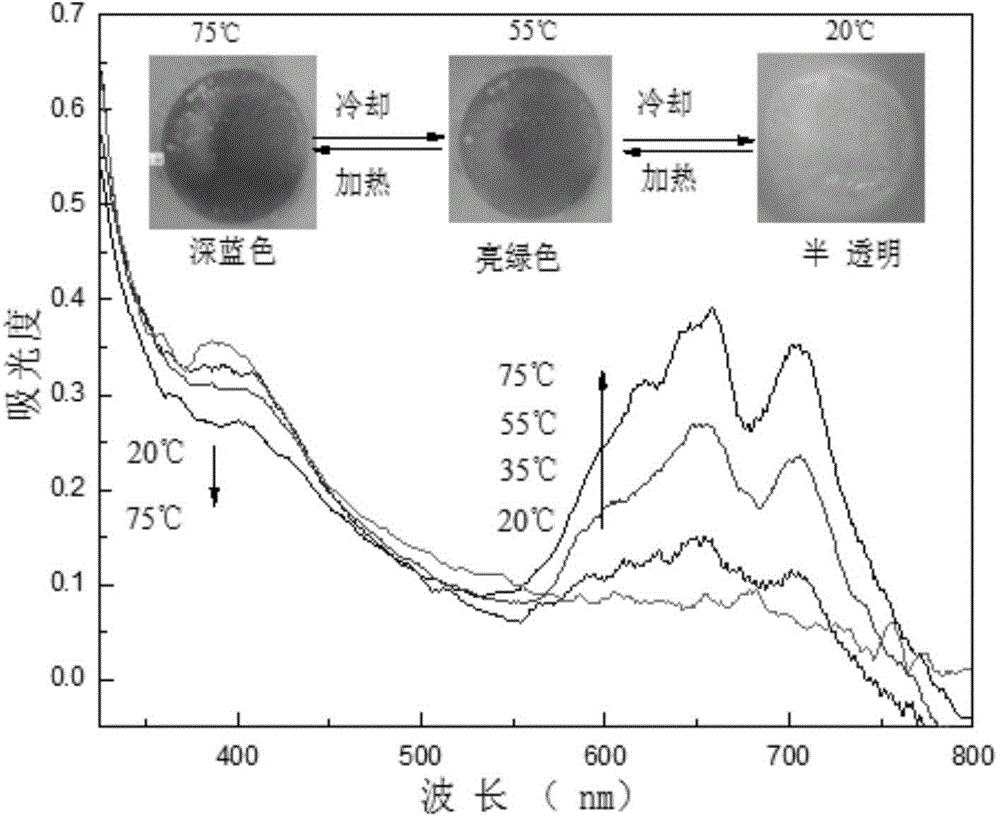

[0022] According to Cetyl Trimethyl Ammonium Chloride C 19 H 42 The molar ratio of ClN (CTAC) to metal nickel salt is 2:1. Weigh 1.28g CTAC and 0.475g nickel chloride hexahydrate NiCl 2 .6H 2 O, dissolved in 5mL of ethanol solution, shake to completely dissolve, then heat to evaporate the ethanol until nearly dry, cool, overnight until the ethanol is completely volatilized, to obtain a green translucent gel, which is a reversible thermochromic material. When the gel-like solid is heated to 50-80°C, the color of the solid changes from green translucent to dark blue opaque.

Embodiment 2

[0024] According to Cetyl Trimethyl Ammonium Chloride C 19 H 42 The molar ratio of ClN (CTAC) to metal nickel salt is 5:1. Weigh 1.28g CTAC and 0.190g nickel chloride hexahydrate NiCl 2 .6H 2 O, dissolve in 5mL ethanol solution, shake to completely dissolve, then heat to evaporate the ethanol until nearly dry, cool, overnight until the ethanol is completely volatilized, to obtain a grass-green translucent gel, which is a reversible thermochromic material. When the gel-like solid is heated to 50-80°C, the color of the solid changes from grass green translucent to dark blue opaque.

Embodiment 3

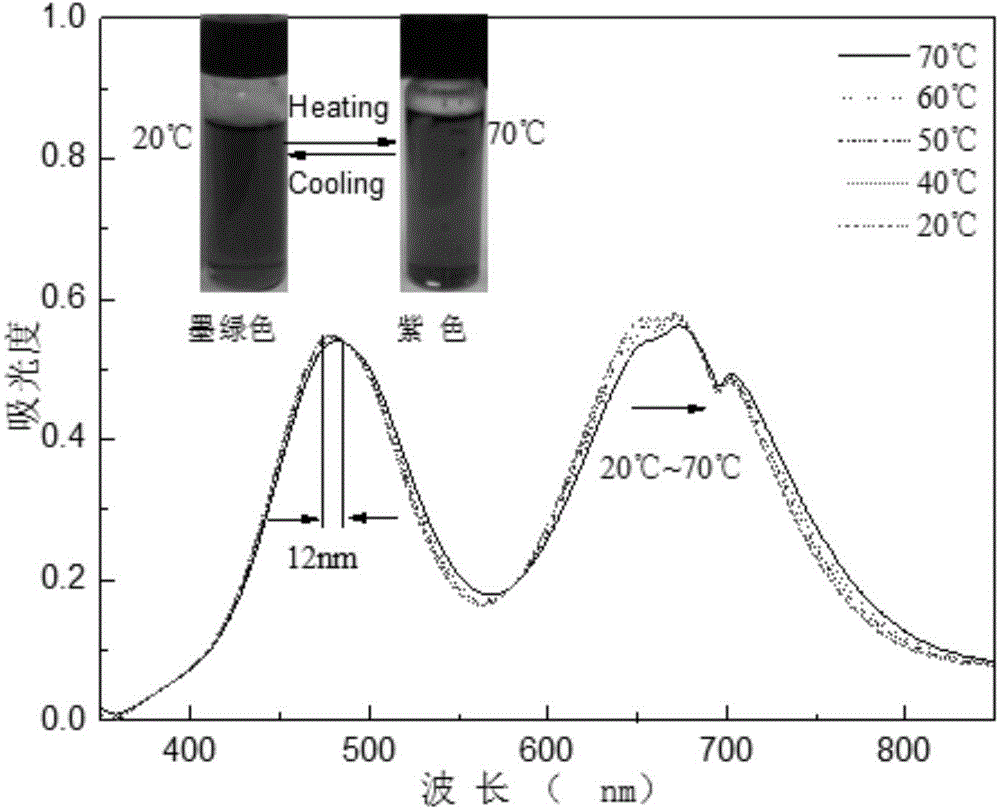

[0026] According to Cetyl Trimethyl Ammonium Chloride C 19 H 42 The molar ratio of ClN (CTAC) to metal chromium salt is 2:1. Weigh 1.28g CTAC and 0.5326g chromium chloride hexahydrate CrCl 3 .6H 2 O, dissolved in 5mL ethanol solution, shake to completely dissolve, then heat to evaporate the ethanol until nearly dry, cool, overnight until the ethanol is completely volatilized, then a dark green gel is obtained, which is a reversible thermochromic material. When the gel-like solid is heated to 50-80°C, the color of the solid changes from dark green to dark purple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com