Compound gas hydrate anti-agglomerant and application thereof

A technology of gas hydrate and anti-polymerization agent, which is applied in the direction of drilling composition, gas/liquid distribution and storage, mechanical equipment, etc., and can solve the problem of poor polymerization inhibition effect, low gas separation ability, and reduced gas transportation capacity of the system and other problems, to achieve the effect of reducing operating pressure and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

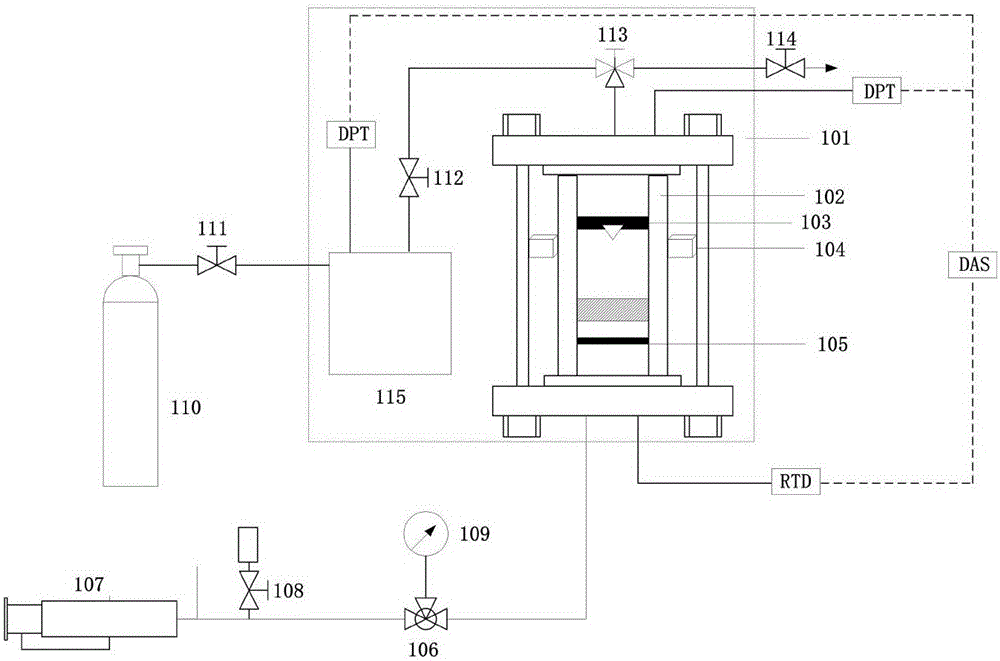

[0039] This embodiment provides a composite gas hydrate anti-polymerization agent, which is composed of a quaternary ammonium salt type cationic surfactant TBAB and a polyol type nonionic surfactant Span 20 in a mass ratio of 2:1 . The above-mentioned composite gas hydrate anti-polymerization agent is added to a water-oil mixed system with a water content of 20% (calculated on the basis of the sum of the volumes of water and oil), and then the composite gas hydrate provided in this example is added. The application effect of the anti-aggregation agent was evaluated. It is proposed to study the state change of methane hydrate formation process system in the water / diesel emulsion containing the compound gas hydrate anti-polymerization agent. The experimental setup used is figure 1 As shown, the device has been described in patent ZL201310014858.9. The specific steps of using this high-pressure transparent sapphire reactor device to carry out the application evaluation test ar...

Embodiment 2

[0045]This embodiment provides a composite gas hydrate anti-polymerization agent, which is composed of a quaternary ammonium salt type cationic surfactant TBAB and a polyol type nonionic surfactant Span 20 in a mass ratio of 3:1 . The above-mentioned composite gas hydrate anti-polymerization agent is added to a water-oil mixed system with a water content of 25% (calculated on the basis of the volume of water and oil), and then the composite gas hydrate provided in this example is added. The application effect of the anti-aggregation agent was evaluated. It is proposed to study sour gas-bearing natural gas (H 2 S / CO 2 / CH 4 / N 2 ) in the water / diesel emulsion containing the compound gas hydrate anti-polymerization agent to form a hydrate process system state change. The experimental setup used is also figure 1 The experimental setup containing the high pressure transparent sapphire autoclave is shown.

[0046] In the present embodiment, the oil-water system in the reacti...

Embodiment 3

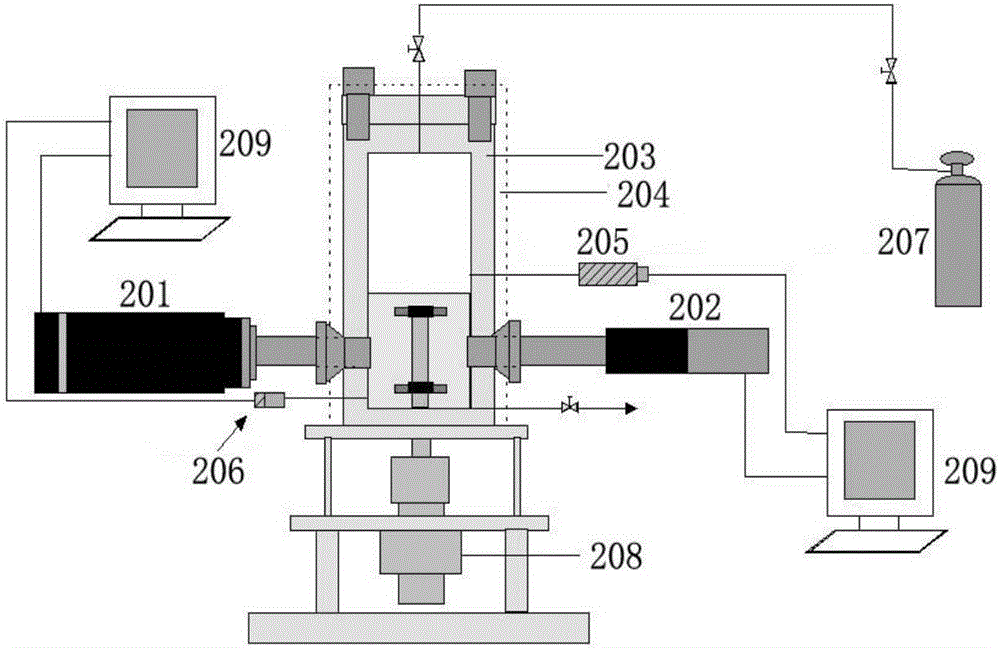

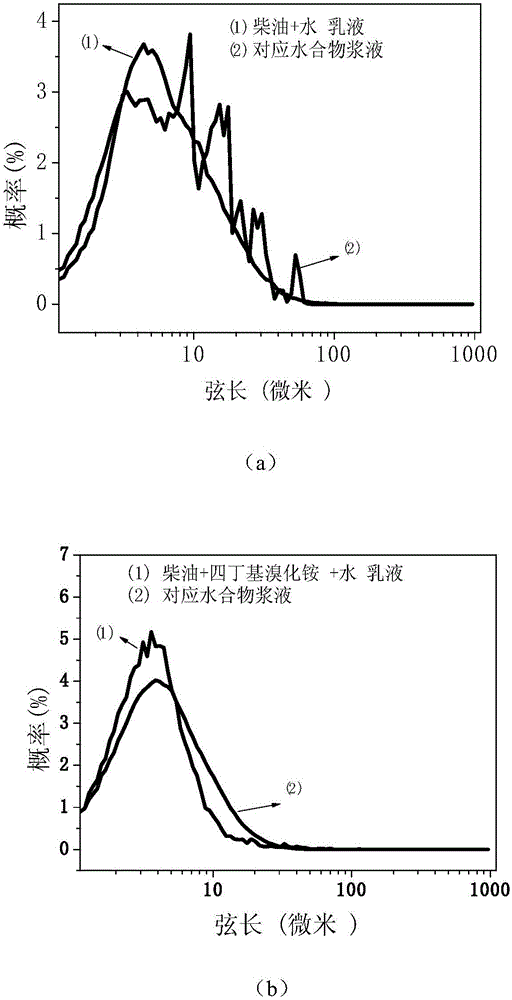

[0050] This embodiment provides a composite gas hydrate anti-polymerization agent, which is composed of a quaternary ammonium salt type cationic surfactant TBAB and a polyol type nonionic surfactant Span 20 in a mass ratio of 3:1 . The change of particle chord length in the system during the formation of hydrate of acid gas-containing natural gas in the water / diesel emulsion containing the compound gas hydrate anti-aggregation agent is planned to be studied. The experimental setup used was figure 2 Shown is a blind autoclave device containing a visible microscope probe (PVM) and a focused beam reflection measuring probe (FBRM) laser particle sizer probe, which has been described in patent CN201410075004.6. The specific steps to carry out the test are as follows:

[0051] Before the start of the experiment, the autoclave and all the connecting parts were rinsed with distilled water, and then dried with nitrogen. Clean the PVM measuring probe 201 and the FBRM measuring probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com