Preparation method of core-shell structured Pd-Co/CN@SiO2 nano-catalyst

A nano-catalyst, core-shell structure technology, applied in the preparation of organic compounds, catalysts for physical/chemical processes, preparation of amino compounds, etc., can solve the problems of easy sintering of metal nanometers, high equipment requirements, and unfavorable industrial production. The effect of improving catalytic activity, easy operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 0.45g Co(NO 3 ) 2 ·6H 2 O, 0.05g K 2 PdCl 4 Dissolve in 3ml deionized water, 5.5g 2-MeIM dissolved in 20ml deionized water, mix the two solutions and stir for 24h, filter and dry to obtain palladium-loaded cobalt-based metal organic framework Pd 2+ / ZIF-67. Take 30 mg palladium-loaded cobalt-based metal-organic framework Pd 2+ / ZIF-67 was dispersed in a mixture of 33ml deionized water and 20ml absolute ethanol, 250mg 2-methylimidazole was added, 0.55ml 25% CTAC aqueous solution was added after ultrasonication for 10min, and 0.4ml tetraethyl silicate was added after stirring for 20min. After 2h, filter and dry. The resulting mass was placed in a tube furnace, N 2 Calcined slowly at 800°C for 4 hours under atmosphere to obtain core-shell structure Pd-Co / CN@SiO 2 nanocatalyst.

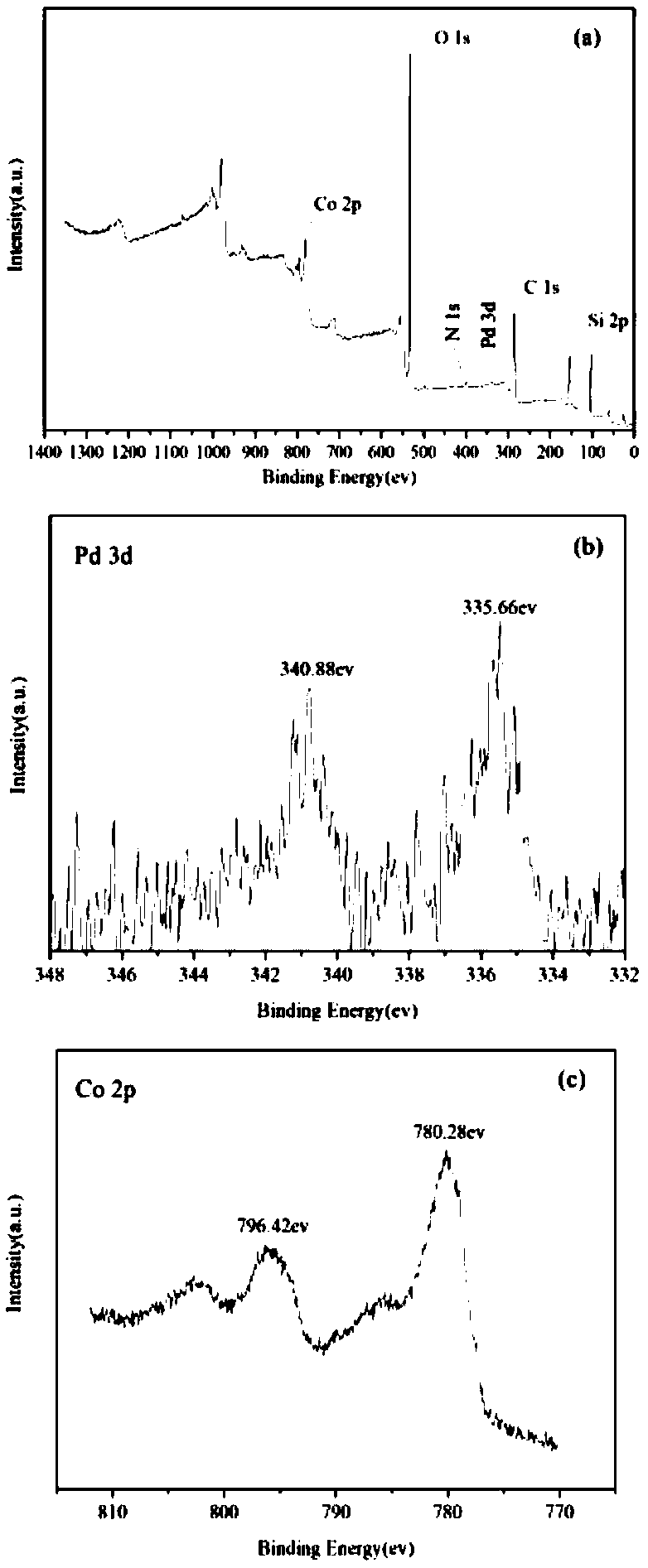

[0023] figure 1 It is the X-ray photoelectron energy spectrum of the catalyst. Figure b is the 3d spectrum of Pd. It can be seen from the figure that the binding energies of the two main...

Embodiment 2

[0027] It is basically the same as Example 1, except that the calcination temperature is changed to 750°C.

Embodiment 3

[0029] It is basically the same as Example 1, except that the calcination temperature is changed to 850°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com