Method for preparing adhesive abamectin polydopamine microcapsule by employing emulsion interface polymerization method

A technology of abamectin polydopamine and interfacial polymerization method, applied in the directions of botanical equipment and methods, pesticides, animal repellents, etc. Problems such as large usage and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

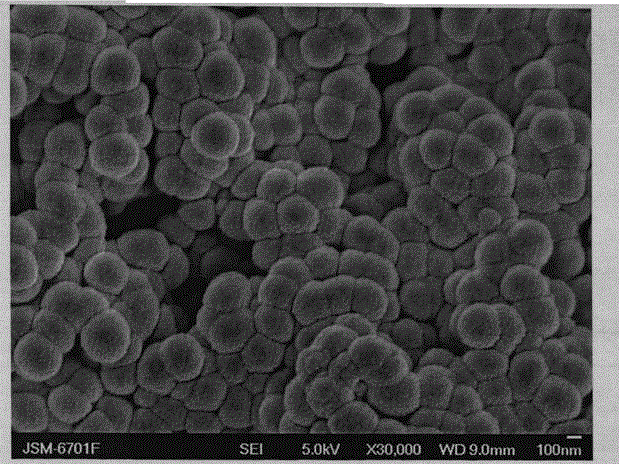

Image

Examples

Embodiment 1

[0008] Example 1 Dissolve 1.5g cetyltrimethylammonium chloride (1.5% m / v aqueous phase) in 100mL Tris-HCl (pH=8.5) buffer solution to obtain the aqueous solution of surfactant, 0.1g avi Bacterin was dissolved in 10mL of n-butanol to obtain the oil phase; then the oil phase was quickly added to the above aqueous solution and stirred vigorously for 30min; then 0.1g of dopamine (concentration: 1mg / mL) was added to carry out oxidative self-polymerization on the emulsion interface, 300r / min mechanical stirring at room temperature for 24h. Centrifugal washing with water for 3-4 times, vacuum drying at 45° C. to obtain microcapsules with adhesion and photostability, and the microcapsules have temperature and pH controlled release. The loading capacity of abamectin in the microcapsule can reach 66.5%, and the yield can reach 75%-85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com