Preparation method for gallium-based gallium-indium alloy nanorod

A technology of alloy nano-gallium indium, which is applied in the field of preparation of gallium and gallium-indium alloy nanorods, can solve the problems of complex system, unfavorable post-processing or surface modification, and difficulty in reaching the nanometer scale, and achieve the effect of simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The volume ratio of deionized water and ethanol used in this example is 1:1, the liquid metal used is pure gallium, and the instrument used for preparation is an ultrasonic breaker.

[0018] Put pure gallium and mixed dispersant into a beaker according to 1g of liquid metal corresponding to 20mL of dispersion medium, ultrasonically break at 800W for 4h, after the ultrasonication is over, let it stand for 12h, centrifuge at 1000*G for 3min, and take the supernatant for storage.

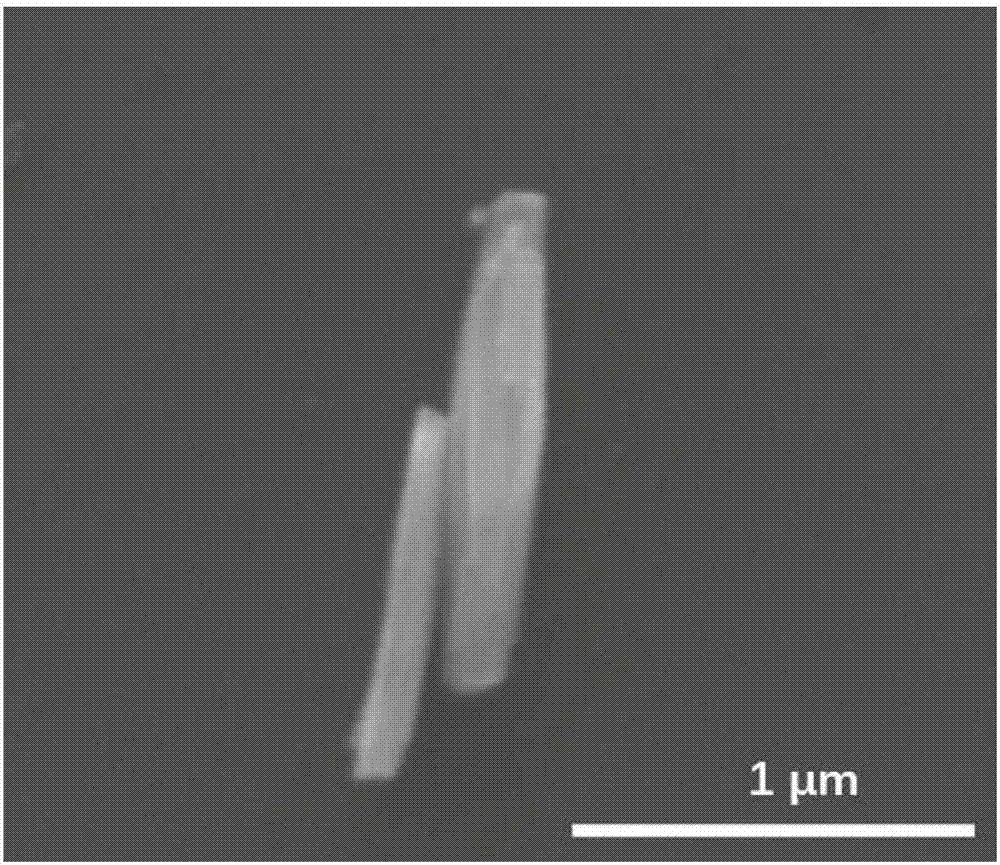

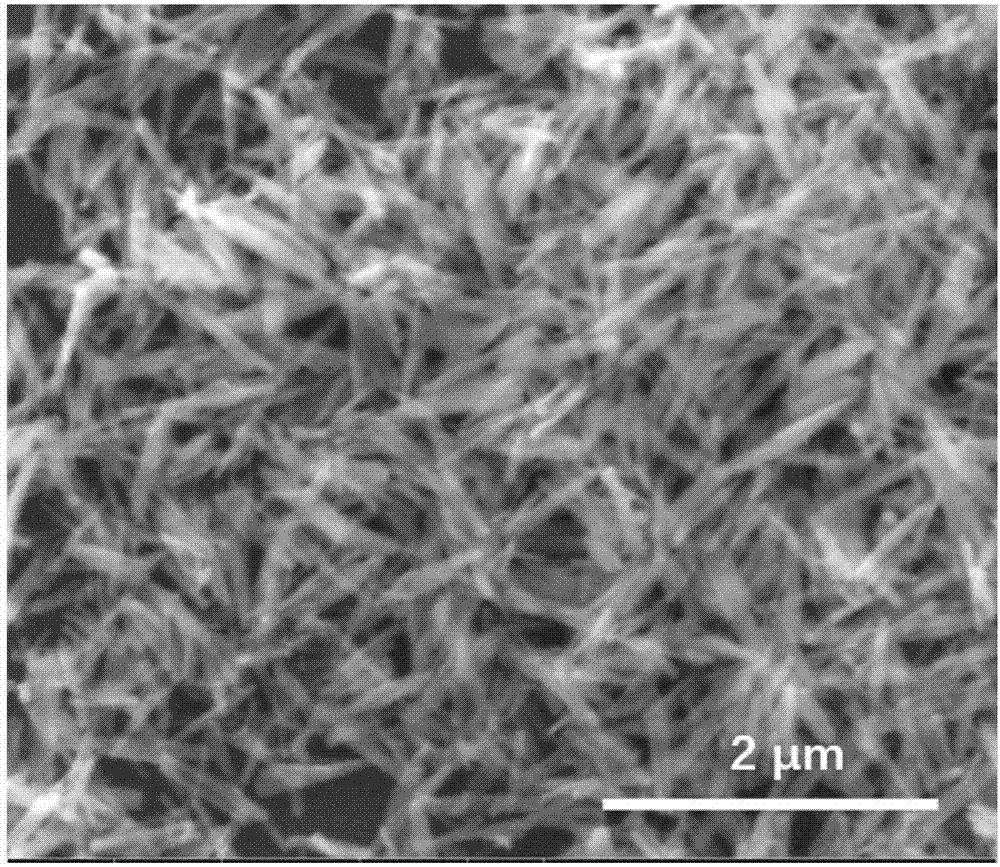

[0019] The prepared nanorod has a length of 1-1.5 μm and a diameter of about 200 nm.

Embodiment 2

[0021] The volume ratio of deionized water and ethanol used in this example is 1:3, the liquid metal used is gallium-indium alloy, and the instrument used for preparation is an ultrasonic breaker.

[0022] Put pure gallium-indium alloy and mixed dispersant into a beaker according to 1g of liquid metal corresponding to 20mL of dispersion medium, ultrasonically break for 3h at 600W power, after the ultrasonication is over, let it stand for 12h, centrifuge at 1000*G for 3min, and take the supernatant for storage.

[0023] The prepared nanorod has a length of 0.9-1.2 μm and a diameter of about 120 nm.

Embodiment 3

[0025] The volume ratio of deionized water to ethanol used in this example is 1:5, the liquid metal used is gallium-indium alloy, and the instrument used for preparation is an ultrasonic breaker.

[0026] Put the pure gallium-indium alloy and the mixed dispersant into a beaker according to 1g of liquid metal corresponding to 20mL of dispersion medium, ultrasonically crush at 700W for 2h, after the ultrasonication is over, let it stand for 12h, centrifuge at 1000*G for 3min, and take the supernatant for storage.

[0027] The prepared nanorod has a length of 1-1.2 μm and a diameter of about 100 nm.

[0028] Evaluation methods and results of gallium-based liquid metal nanorod structures of the present invention.

[0029] Scanning electron microscope (FEI Quanta 200F, USA) and transmission electron microscope (Hitachi H-7650, Japan) were used to characterize the morphology of gallium-based liquid metal nanorods. In the electronic mode, the curved surface morphology of the side ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com