Preparation method of low-cost strong-acid hierarchical-pore Beta zeolite

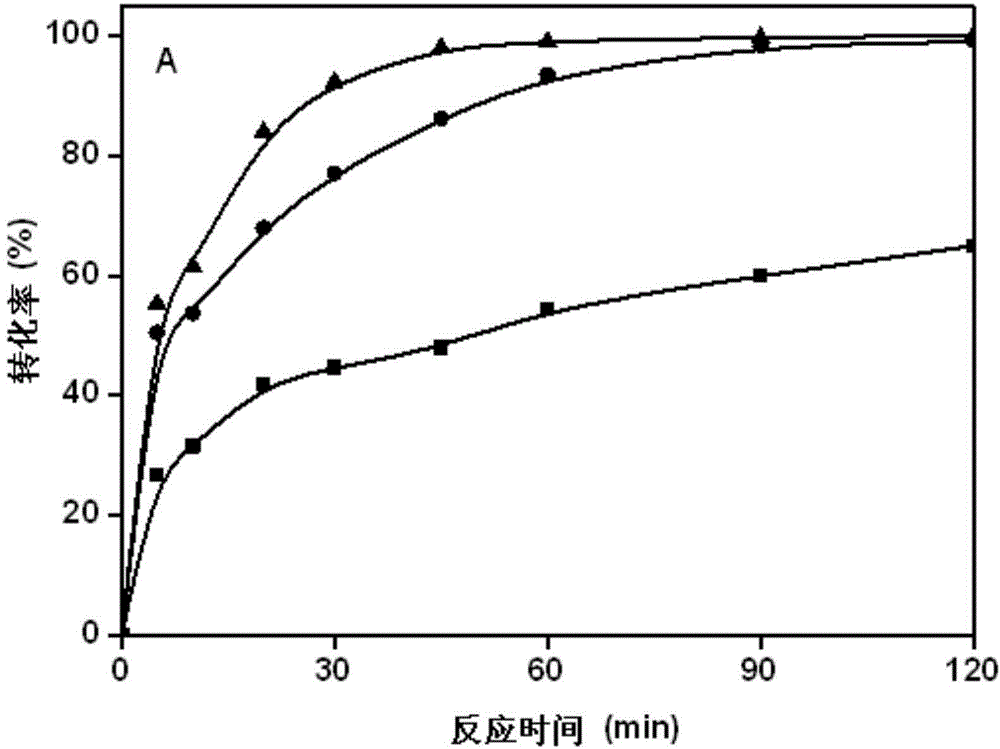

A beta zeolite and multi-level pore technology, which is applied in the field of preparation of multi-level pore Beta zeolite, can solve the problems of molecular sieve acid weakening, etc., and achieve the effects of improving reactivity, reducing cost, large reaction space and anti-deactivation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

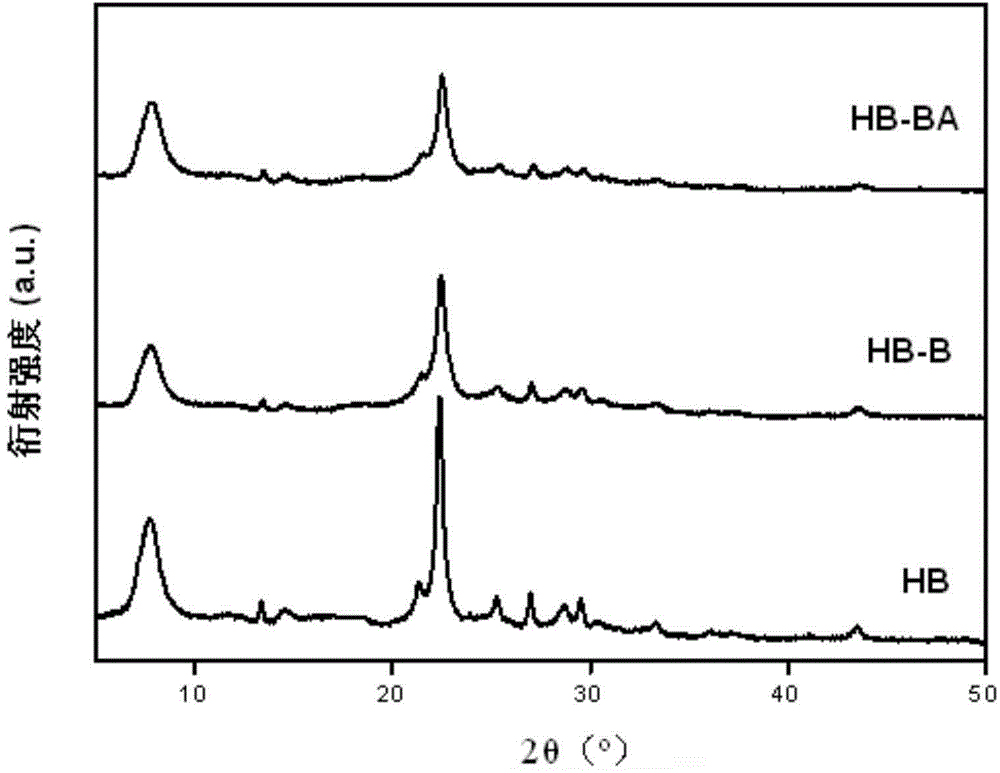

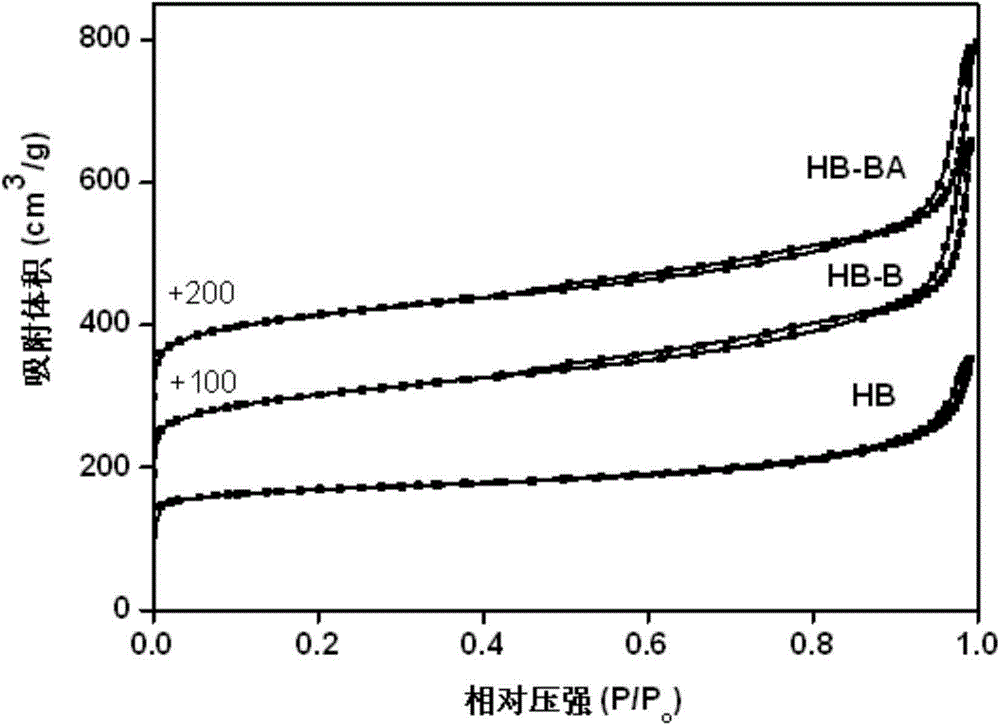

[0016] Specific embodiment one: the preparation method of the cheap strongly acidic hierarchical porous Beta zeolite of the present embodiment is carried out according to the following steps:

[0017] 1. Calcining Beta zeolite at 500-600°C for 3-10 hours to obtain microporous hydrogen Beta zeolite;

[0018] 2. Add the microporous hydrogen Beta zeolite into the alkali solution with a concentration of 0.1-2mol / L, stir at 0-100°C for 0.5-2h, and then wash the microporous hydrogen Beta zeolite with deionized water until the filtrate becomes medium properties, and then dried at 100-120°C to obtain sodium-type desiliconized hierarchically porous Beta zeolite;

[0019] 3. Add the sodium-type desiliconized hierarchically porous Beta zeolite obtained in step 2 into an aqueous ammonium nitrate solution with a concentration of 1-2 mol / L and exchange for 1-5 times, each time for 0.5-2 hours, and calcinate at 500-600°C Obtain hydrogen type desilication hierarchical porous Beta zeolite aft...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the alkaline solution in step 2 is NaOH aqueous solution. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solid-to-liquid ratio of the microporous hydrogen Beta zeolite to the alkali solution in step 2 is 1 g:10-50 mL. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com