Production method of lithium secondary battery drop water ferric fluoride anode material

A lithium secondary battery and positive electrode material technology, applied in the direction of fluoride preparation, electrode manufacturing, battery electrodes, etc., can solve the problems of product shape dependence, time and energy consumption, high consumables, etc., and achieve regular surface appearance and uniform distribution , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh FeCl at a molar ratio of 1:4 3 and about 25g of ammonia water, mix the two materials evenly in an aqueous solution at room temperature, filter with suction to obtain a ferric-alkaline mixture, add 40% hydrofluoric acid to the ferric-alkaline mixture at a molar ratio of 1:4, and put it into a special airtight plastic container Insulated at 50°C for 40 hours to make it evenly mixed. Then remove the excess product from the reaction, wash the remaining material with ethanol and dry it in the air atmosphere for 24 hours, then vacuum-dry the material at 50°C for 36 hours; take out the product, crush it and ball mill it to 5-10 μm in a ball mill , through a 300-mesh sieve to obtain FeF with a purity greater than 95% 3 (H 2 O) 0.33 product.

Embodiment 2

[0027] Weigh Fe at a molar ratio of 1:8.5 2 (SO 4 ) 3 and about 25g of sodium hydroxide, the two materials are mixed uniformly in an aqueous solution at normal temperature, and the water generated is removed by suction filtration to obtain a ferric-alkaline mixture, which is added with 10% hydrofluoric acid in a molar ratio of 1:7, and put Put it into a special airtight plastic container and keep it warm at 75°C for 30 hours to make it mix evenly. Then the excess product of the reaction was removed, and the remaining material was washed with ethanol and dried in an air atmosphere for 30 hours, and then the material was vacuum-dried at 90° C. for 64 hours; the product was taken out, pulverized and ball-milled in a ball mill to 5 ~10μm, through 200 mesh sieve, get FeF with purity greater than 95% 3 (H 2 O) 0.33 product.

Embodiment 3

[0029] Weigh FeNO at a molar ratio of 1:6 3and about 25g of KOH, the two materials are mixed uniformly in aqueous solution at room temperature, and the water generated is removed by suction filtration to obtain a ferric-alkaline mixture, and the ferric-alkaline mixture is added with 30% hydrofluoric acid in a molar ratio of 1:9, and put into In a special airtight plastic container, keep warm at 90°C for 36 hours to make it evenly mixed. Then the excess product of the reaction was removed, and the remaining material was washed with ethanol and dried in an air atmosphere for 10 hours, and then the material was vacuum-dried at 190° C. for 24 hours; the product was taken out, crushed and ball-milled in a ball mill to 5 ~10μm, through 400 mesh sieve, get FeF with purity greater than 95% 3 (H 2 O) 0.33 product.

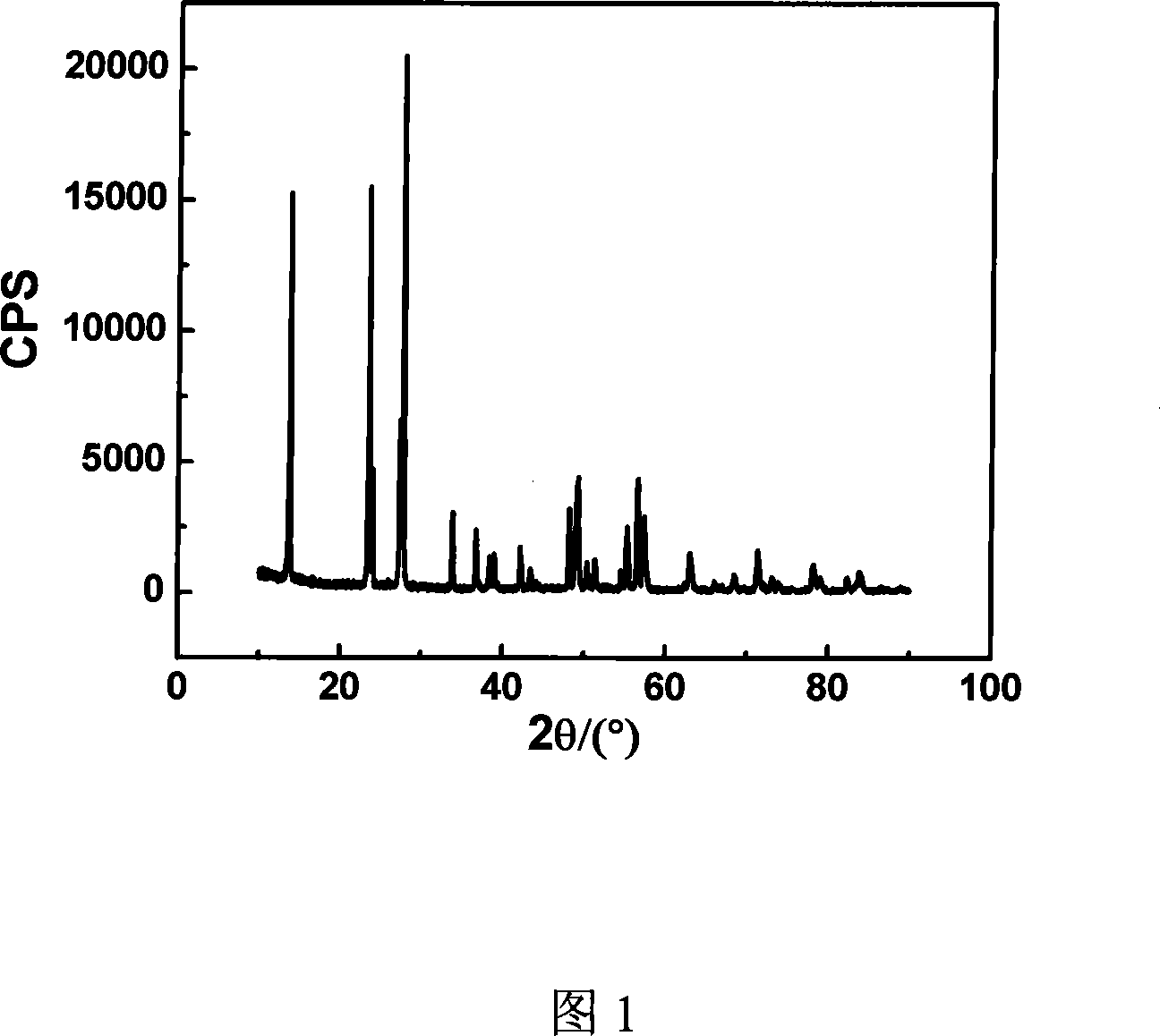

[0030] Fig. 1 is the FeF prepared by the present invention 3 (H 2 O) 0.33 The X-ray Diffraction Spectrum. It can be seen from the figure that the prepared FeF 3 (H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com