Process for producing methionine

A technology for producing methionine and methionine, applied in the field of methionine production, can solve the problems of high equipment cost and poor filterability, and achieve the effects of cost-effectiveness, improved filterability and effective recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

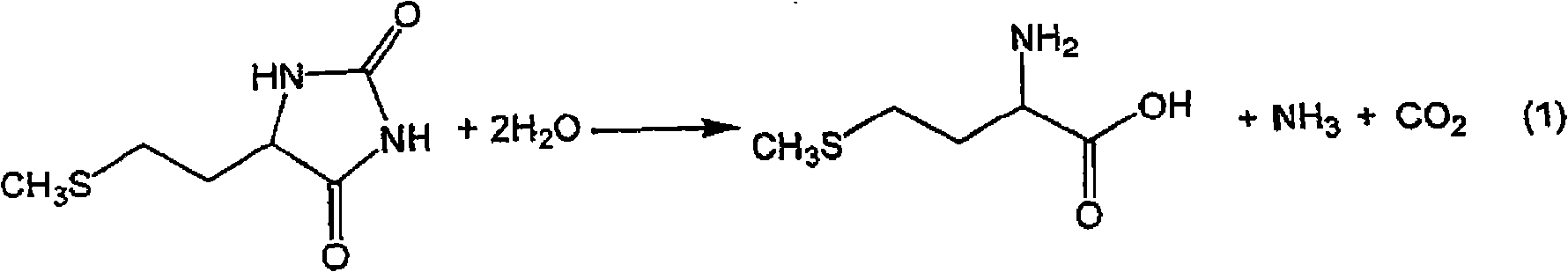

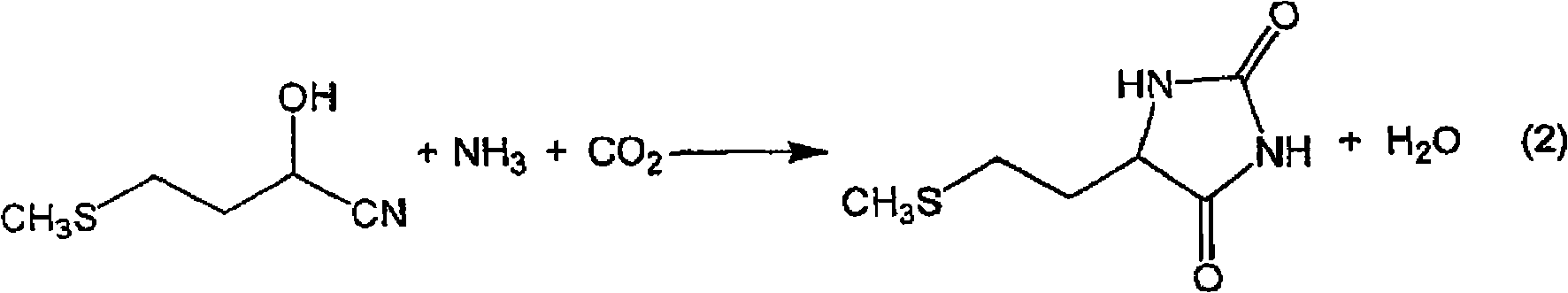

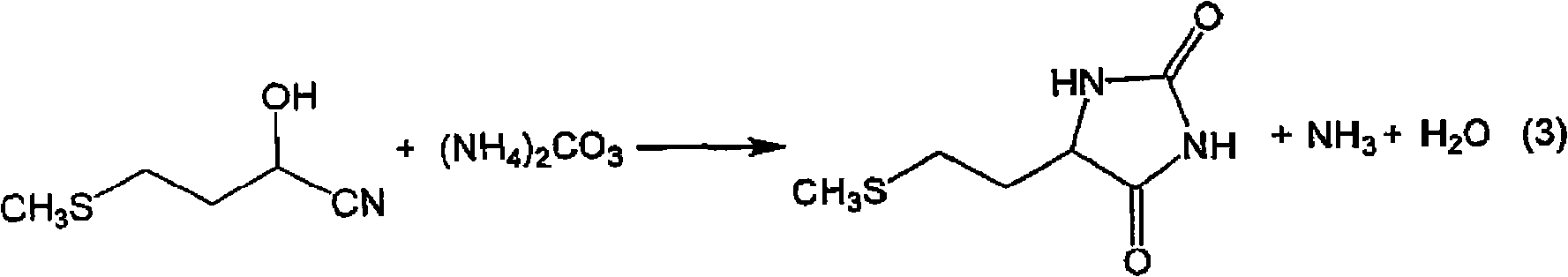

Method used

Image

Examples

Embodiment 1

[0059] [Reaction step (1)]

[0060] When a solution of 100 parts / hour 18.7% 5-[2-(methylthio)ethyl]imidazolidine-2,4-dione in water, 1.0 parts / hour potassium hydroxide, 67.6 parts / hour pre-prepared The first concentrated solution of the first crystal mother liquor (containing 6.0% methionine and 13.5% potassium), 25.8 parts / hour pre-prepared solution containing the second crystal (containing 7.6% methionine and 18.2% potassium, and the When the wet filter cake is dissolved in the concentrate of the first crystal mother liquor and the solution is concentrated) is added to the reactor, the hydrolysis reaction is carried out at 173-178° C. under a gauge pressure of 0.88 MPa for a residence time of 1 hour.

[0061] [First crystallization step (2)]

[0062] The reaction solution (133.1 parts / hour) obtained by the above-mentioned hydrolysis reaction, 60.7 parts / hour water and 0.023 parts / hour polyvinyl alcohol were mixed, it was added in the crystallizer, and it was placed under th...

reference example 1

[0076] The first concentrate (18.5 parts / hour) of the first crystal mother liquor obtained in Example 1 was concentrated under pressure at 135° C. under a gauge pressure of 0.2 MPa to obtain 12.3 parts / hour second concentrate (the second Second concentration rate: 1.5 times, the total concentration rate of the first and second concentration: 2.6 times). The second concentrate (12.3 parts / hour) and 3.3 parts / hour isopropanol were mixed and added to the crystallizer, and subjected to carbon dioxide pressurized crystallization at 12-16° C. under a gauge pressure of 0.3 MPa. The resulting slurry was subjected to pressure filtration under a filter gauge pressure of 0.3 MPa. At this time, the specific filtration resistance of the wet cake was 0.55×10 as measured according to the following procedure 10 m / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com