Magnetic bead-based sample treatment and nucleic acid automatic extraction system

A technology for automatic extraction and nucleic acid extraction, which is applied in the fields of biomass post-processing, biological material pre-treatment, and stress-stimulated microbial growth methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

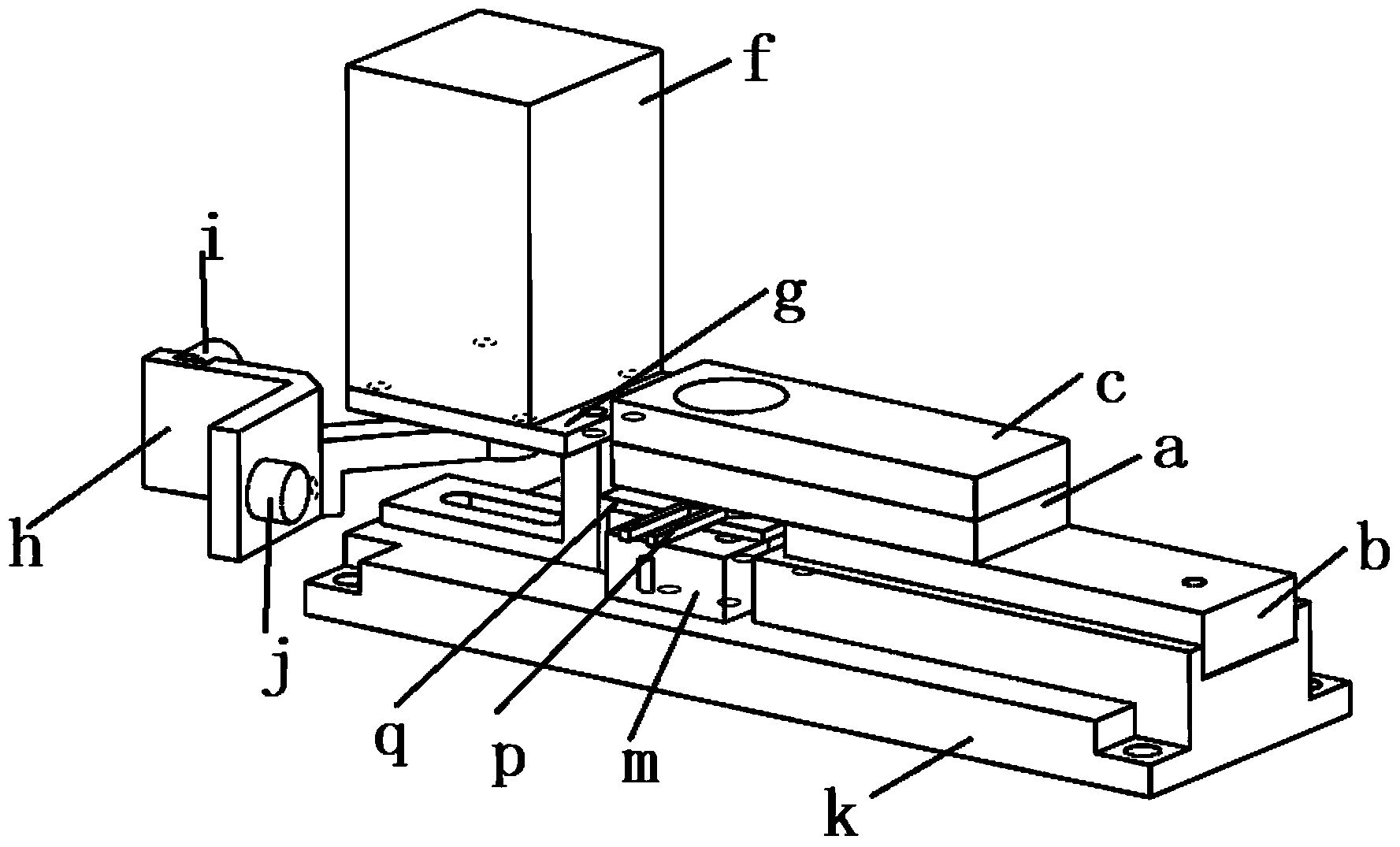

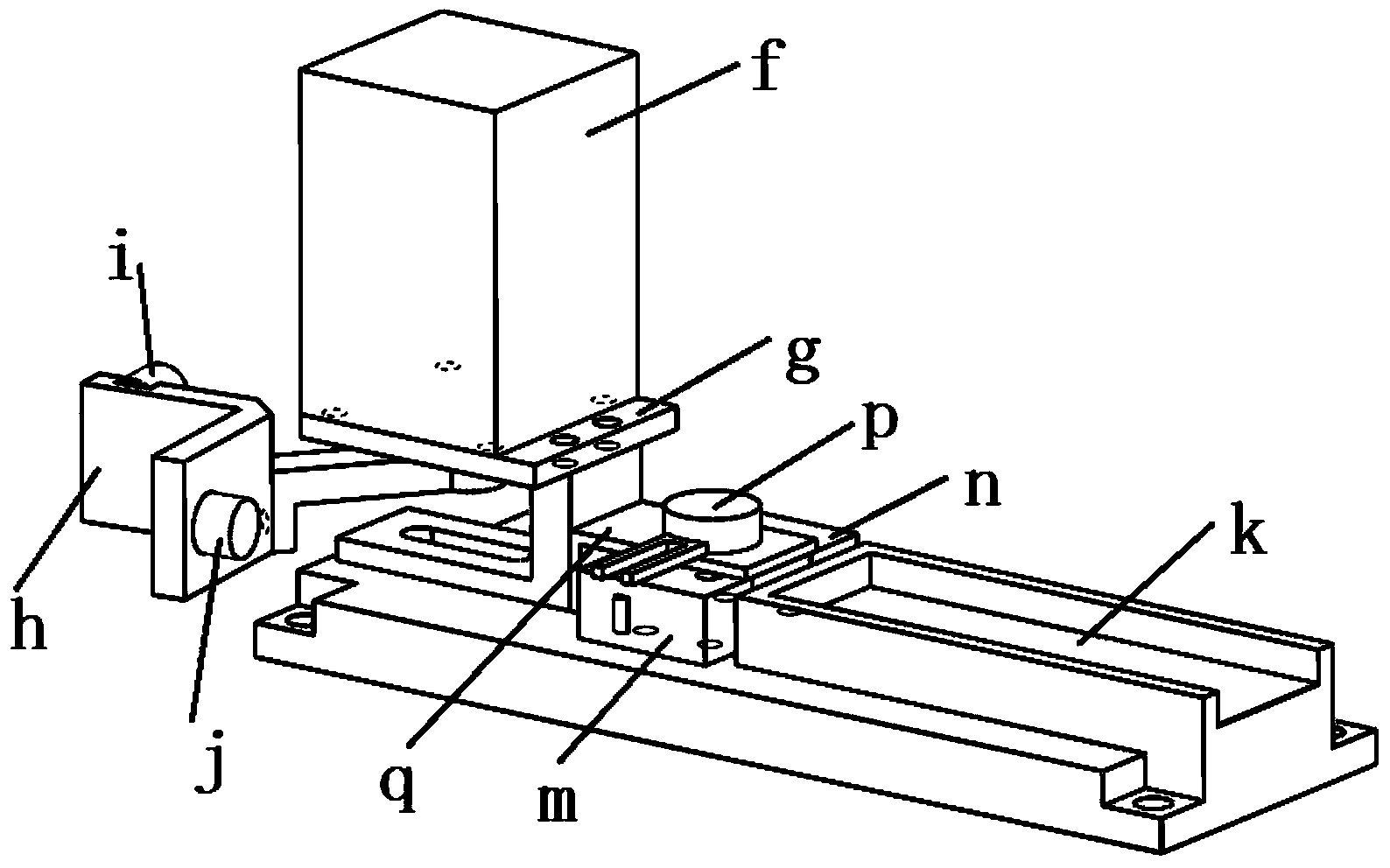

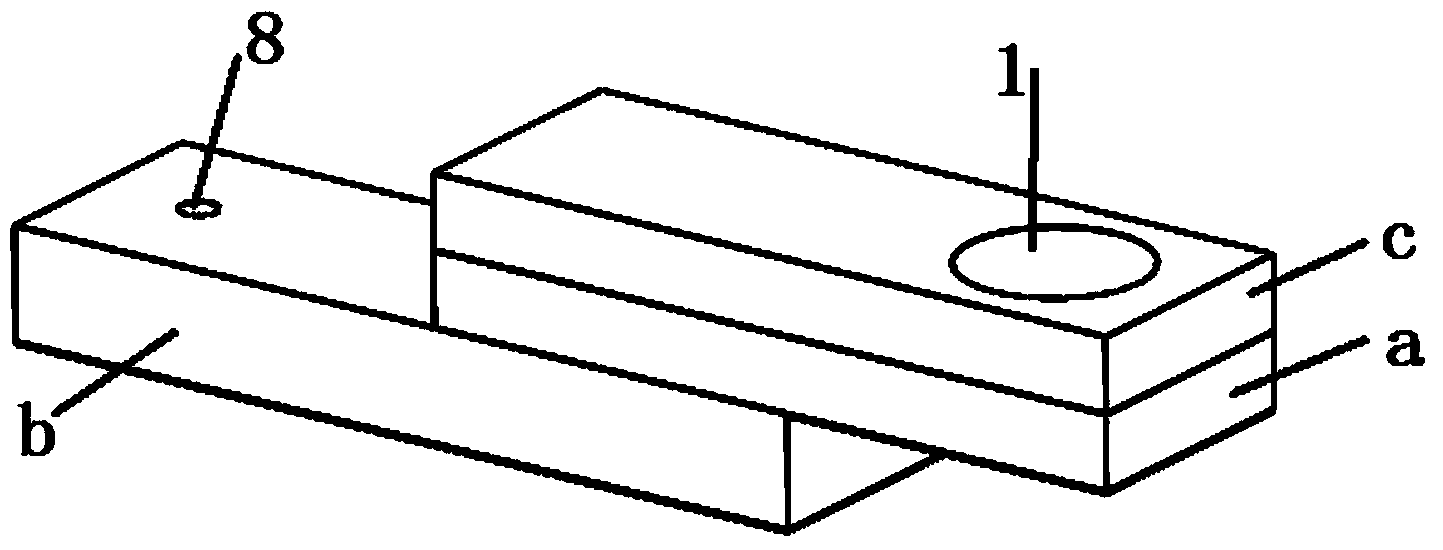

[0055] An automatic nucleic acid extraction system based on the principle of magnetic bead adsorption, which can automatically complete the operations of cell lysis, nucleic acid purification, and nucleic acid elution, and finally obtain a nucleic acid sample template suitable for gene amplification reactions. The principle of the biological reaction is as follows: the virus particles in the reaction sample are cleaved by the lysate, and the nucleic acid released after the cell lysis is absorbed by the magnetic beads, and then various kinds of washing liquid are used to remove all kinds of biological impurities in the sample, such as cell walls, etc. Proteinoid removal, nucleic acid purification, and finally, the nucleic acid is separated from the magnetic beads with an eluent to obtain a high-purity nucleic acid template. An inverted U-shaped connector-type dam channel is designed in the chip to connect the reaction chamber with the waste liquid chamber. Based on the siphon pr...

Embodiment 2

[0060] An automatic nucleic acid extraction system based on the principle of magnetic bead adsorption, which can automatically complete the operations of cell lysis, nucleic acid purification, and nucleic acid elution, and finally obtain a nucleic acid sample template suitable for gene amplification reactions. In a fully automatic and closed sampling working mode, a reaction reagent storage module is integrated on the microfluidic chip. During the reaction process, each reaction reagent is gradually injected into the reaction chamber according to the operation steps of the nucleic acid extraction reaction. Fully automated nucleic acid extraction with integrated microfluidic chips. The principle of the biological reaction is as follows: the virus particles in the reaction sample are cleaved by the lysate, and the nucleic acid released after the cell lysis is absorbed by the magnetic beads, and then various kinds of washing liquid are used to remove all kinds of biological impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com