Method for preparing light olefins through fluid catalytic cracking of naphtha

A fluidized catalysis and naphtha technology, which is used in hydrocarbon cracking to produce hydrocarbons, chemical instruments and methods, physical/chemical process catalysts, etc. Activity and diene yield, effect of reducing diffusion limit, increasing number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

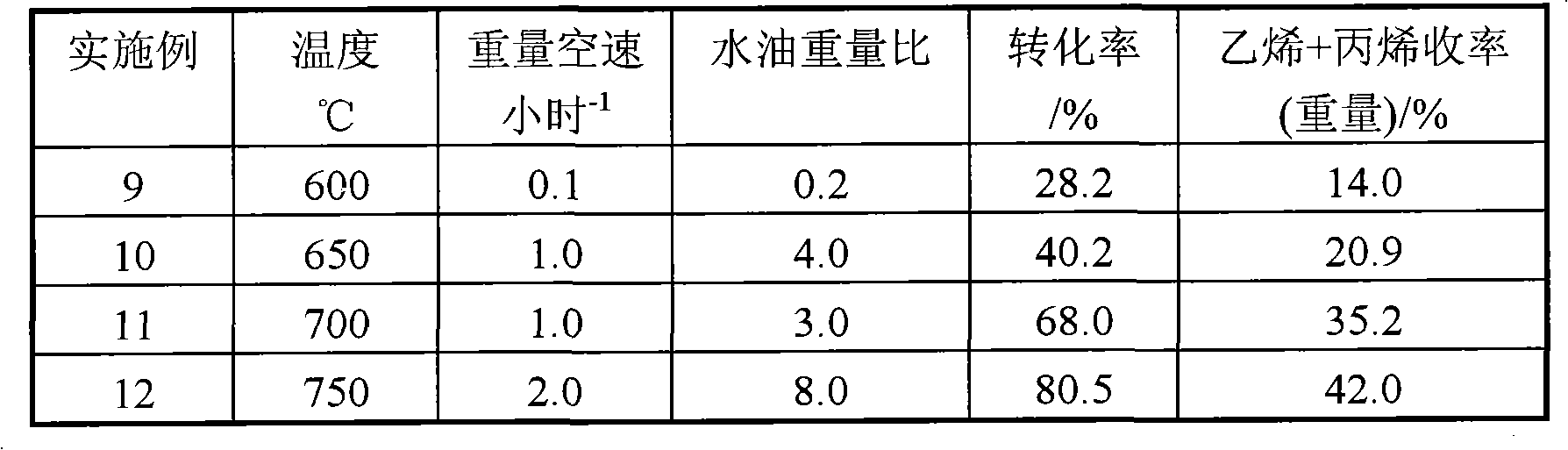

Examples

Embodiment 1

[0018] Tetraethyl orthosilicate, sodium aluminate, sodium hydroxide, tetrapropylammonium hydroxide and water are prepared according to 100SiO 2 : 5.0Al 2 o 3 : 1.0NaOH: 25.0 Tetrapropylammonium hydroxide: 2500H 2 After the O molar ratio was uniformly mixed, crystallization was carried out at 90° C. for 120 hours to obtain a crystallization directing agent.

[0019] Silica sol (SiO 2 40% by weight), sodium aluminate, sodium hydroxide, ethylenediamine and water according to 100SiO 2 : 5Al 2 o 3 : 40.0 Sodium Hydroxide: 50.0 Ethylenediamine: 4000H 2 The molar ratio of O is mixed uniformly to obtain a raw material mixture, and after adding a crystallization directing agent whose weight percentage is 10% of the raw material mixture and stirred evenly, crystallize at 180° C. for 96 hours to obtain small sodium crystals with a grain size of 200-400 nm. Granular ZSM-5 (silicon-alumina molar ratio is 20) zeolite was washed, separated, dried at 120°C for 4 hours, and calcined at ...

Embodiment 2

[0025] Weigh the required amount of ammonium dihydrogen phosphate, lanthanum chloride and magnesium nitrate to prepare an aqueous solution, load it on hydrogen ZSM-5 zeolite b by impregnation method, dry at 120°C for 8 hours, and calcinate at 600°C for 4 hours to obtain a modified zeolite. Weigh the required amount of kaolin, silica sol (SiO 2 The weight content is 40%), the modified zeolite and water are mixed uniformly to obtain a slurry with a solid content of 30%. After spray drying, roasting at 600°C for 3 hours to obtain a cracking catalyst f with a particle size of 20 to 200 microns, the composition in percent by weight is: 30% kaolin: 20% SiO 2 : 40% Zeolite a: 5.0% P 2 o 5 : 8.0% La 2 o 3 : 2.0% MgO.

Embodiment 3

[0027] Weigh the required amount of phosphoric acid, magnesium nitrate and lanthanum oxalate to prepare an aqueous solution, load the hydrogen-form ZSM-5 zeolite b obtained in Example 3 by the impregnation method, dry at 120°C for 8 hours, and roast at 600°C for 4 hours to obtain the modified form Zeolite. Take the required amount of kaolin, alumina (Al 2 o 3 The weight content is 71%), hydrochloric acid (the weight content is 365%, the dosage is 20% of the weight of alumina), the modified zeolite and water are uniformly mixed to obtain a slurry with a solid content of 30%. After spray drying, roasting at 600° C. for 3 hours to obtain a cracking catalyst g with a particle size of 20 to 200 microns, the composition in percent by weight is: 25% kaolin: 20% Al 2 o 3 : 50% Zeolite b: 4.0% P 2 o 5 : 1.0% MgO : 10% La 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com