Process for producing catalyst for producing propylene with methanol

A technology for producing propylene and catalysts from methanol, which is applied in molecular sieve catalysts, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve problems such as low propylene yield, improve propylene selectivity, shorten the length of diffusion paths, and change methanol Effects of transformation product distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

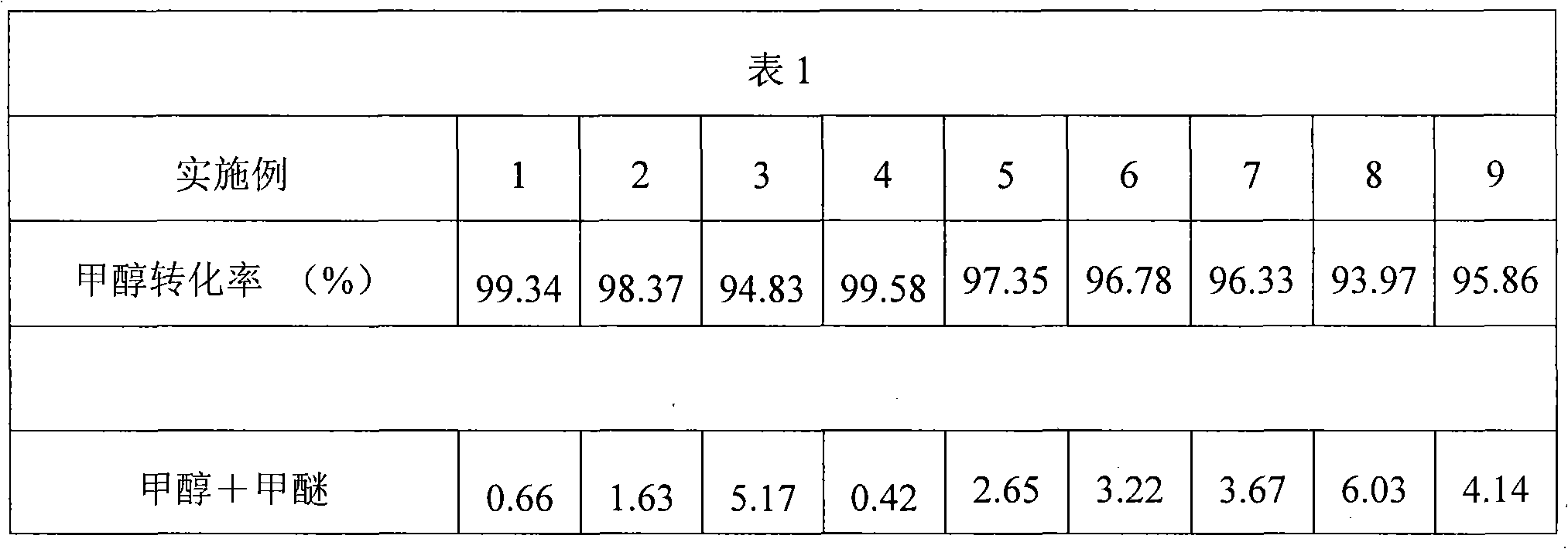

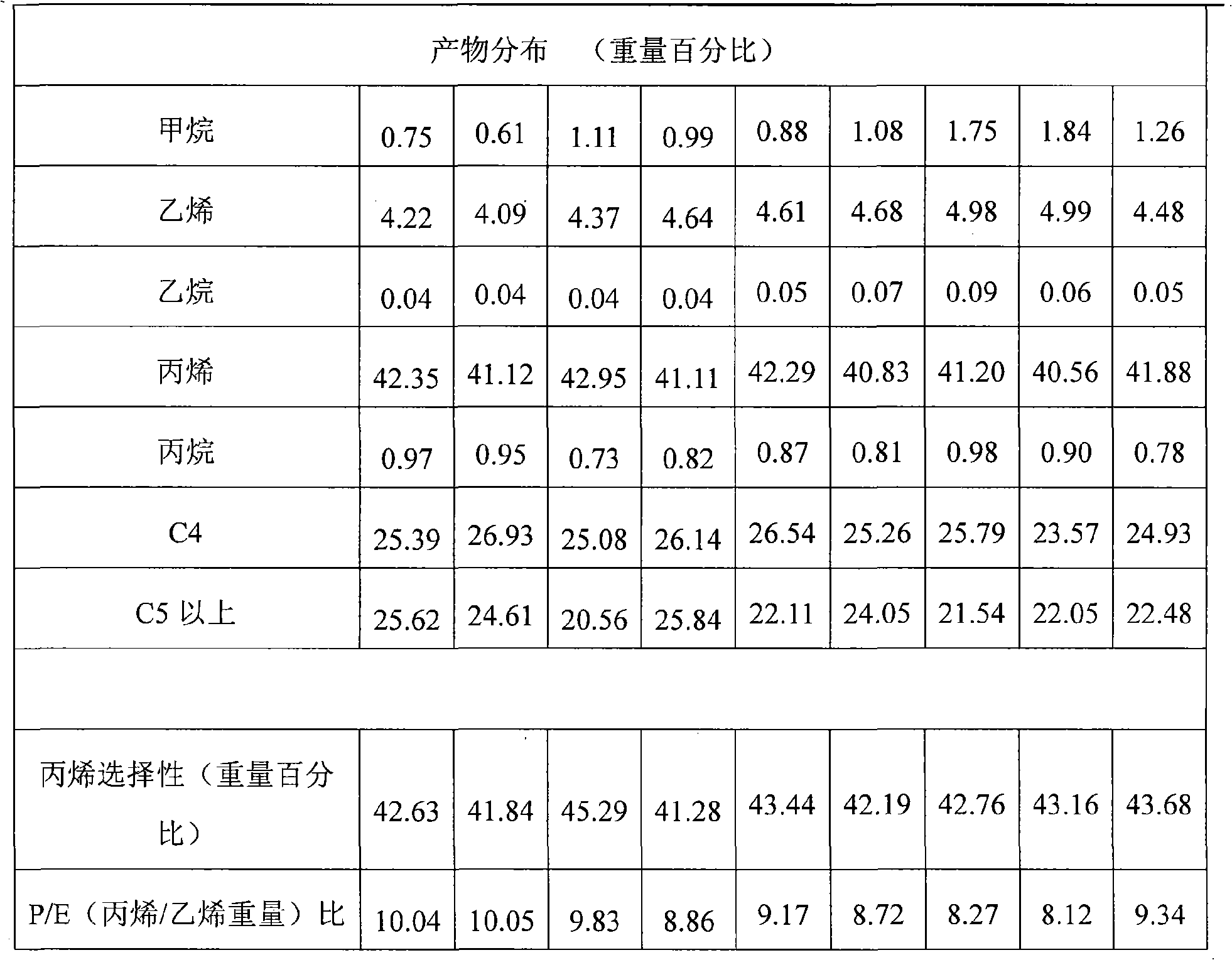

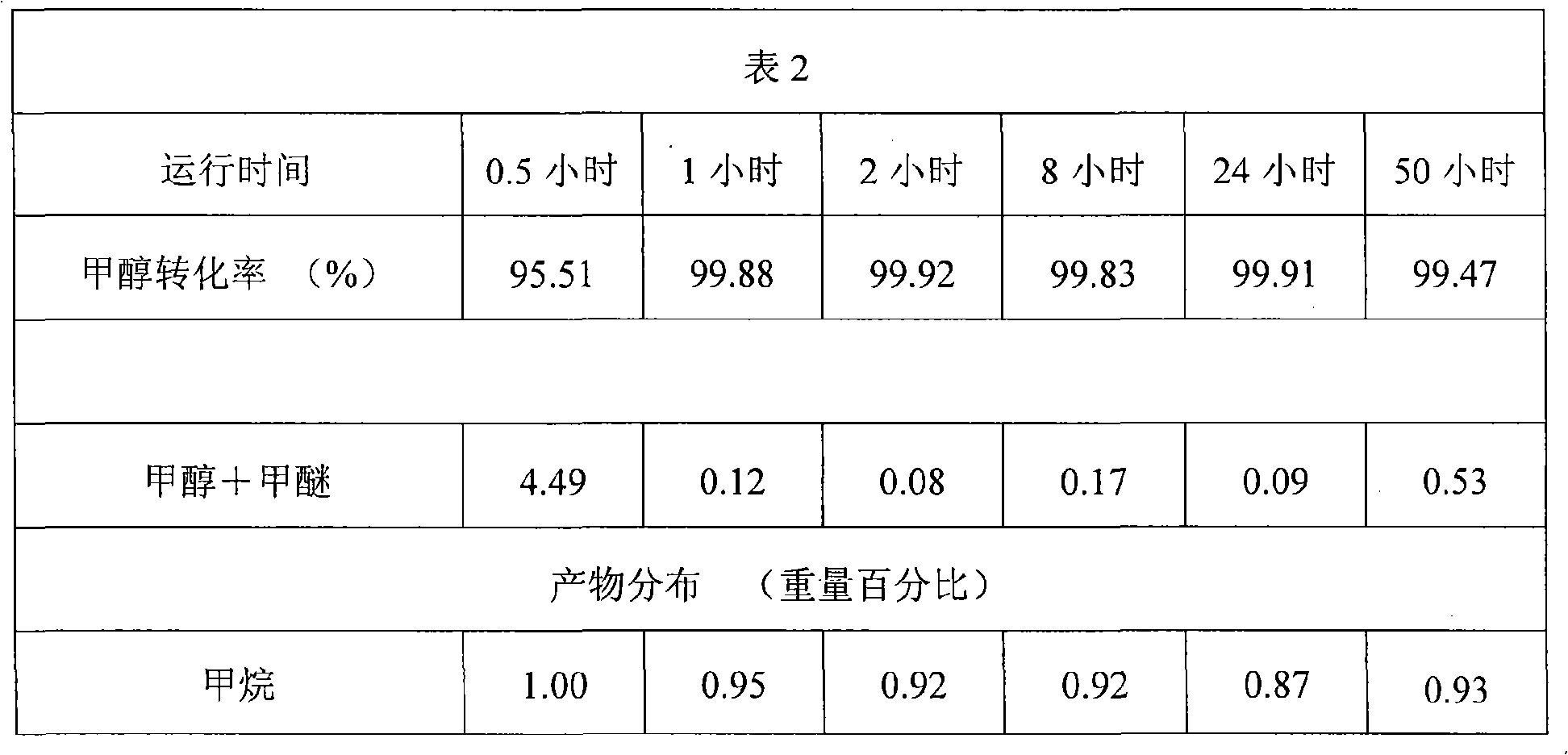

[0021] Using ethyl orthosilicate as the silicon source, sodium metaaluminate as the aluminum source, and tetrapropylammonium hydroxide as the template, mix ethylorthosilicate, aluminum metasilicate, tetrapropylammonium hydroxide, and water to form a sol , its weight ratio is: 98.4: 0.24: 0.12: 1.24, the prepared sol was evaporated at 70°C for 10 hours, then put into a crystallization kettle, and crystallized at 170°C for 3 days, the obtained After washing and drying, the product was exchanged twice with 1 mol / L hydrochloric acid solution at 90° C. for two hours each time. Wash, dry and bake at 500°C for 6 hours to obtain a sample. Tablets were pressed and sieved to 20-40 meshes, and evaluated in a fixed-bed reactor. The reaction conditions are methanol and water mixed feed, wherein the catalyst mass is 3 g, methanol is the raw material, and the feed rates are respectively: methanol, 50 mg / min and water, 10 mg / min. The reaction temperature is 470°C, and the gauge pressure of ...

Embodiment 2

[0023] Using silicic acid as the silicon source, aluminum sulfate as the aluminum source, and tetrapropylammonium hydroxide as the template, silicic acid, aluminum sulfate, tetrapropylammonium hydroxide, and water are mixed to form a sol, and the weight ratio is: 90.3:3.95 : 1.18: 4.57, the prepared sol was evaporated at 70°C for 7 hours, then placed in a crystallization kettle, crystallized at 170°C for 4 days, and the obtained product was washed and dried and used in 1 mole The hydrochloric acid solution per liter was exchanged twice at 90°C for two hours each time. Wash, dry and bake at 500°C for 5 hours to obtain a sample. Tablets were pressed and sieved to 20-40 meshes, and evaluated in a fixed-bed reactor. Under the same reaction conditions as in Example 1, its product distribution is shown in Table 1.

Embodiment 3

[0025] With white carbon black as the silicon source, aluminum nitrate as the aluminum source, and tetrapropylammonium bromide as the template, white carbon black, aluminum nitrate, tetrapropylammonium bromide, sodium hydroxide, and water are mixed to form a sol. The ratio is: 88.2: 6.9: 1.2: 0.1: 3.6, the prepared sol was evaporated at 70°C for 7 hours, then placed in a crystallization kettle, and crystallized at 170°C for 2 days, the obtained After washing and drying, the product was exchanged twice with 1 mol / L hydrochloric acid solution at 90° C. for two hours each time. Wash, dry and bake at 500°C for 5 hours to obtain a sample. Tablets were pressed and sieved to 20-40 meshes, and evaluated in a fixed-bed reactor. Under the same reaction conditions as in Example 1, its product distribution is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com