Method for preparing propylene through C4 disproportionation

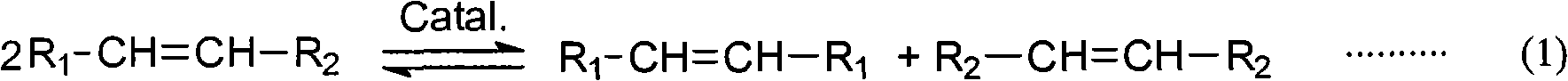

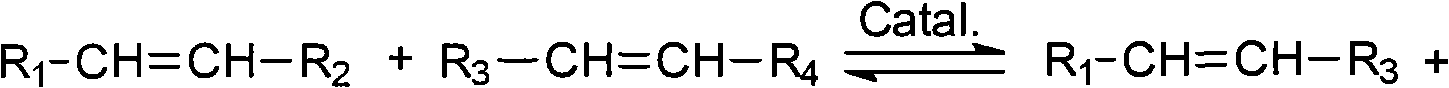

A technology of propylene and disproportionation, which is applied in chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, organic chemistry, etc. It can solve the problems of low activity of ethylene or catalysts, and achieve the effects of increasing yield, increasing yield, and reducing poisonous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

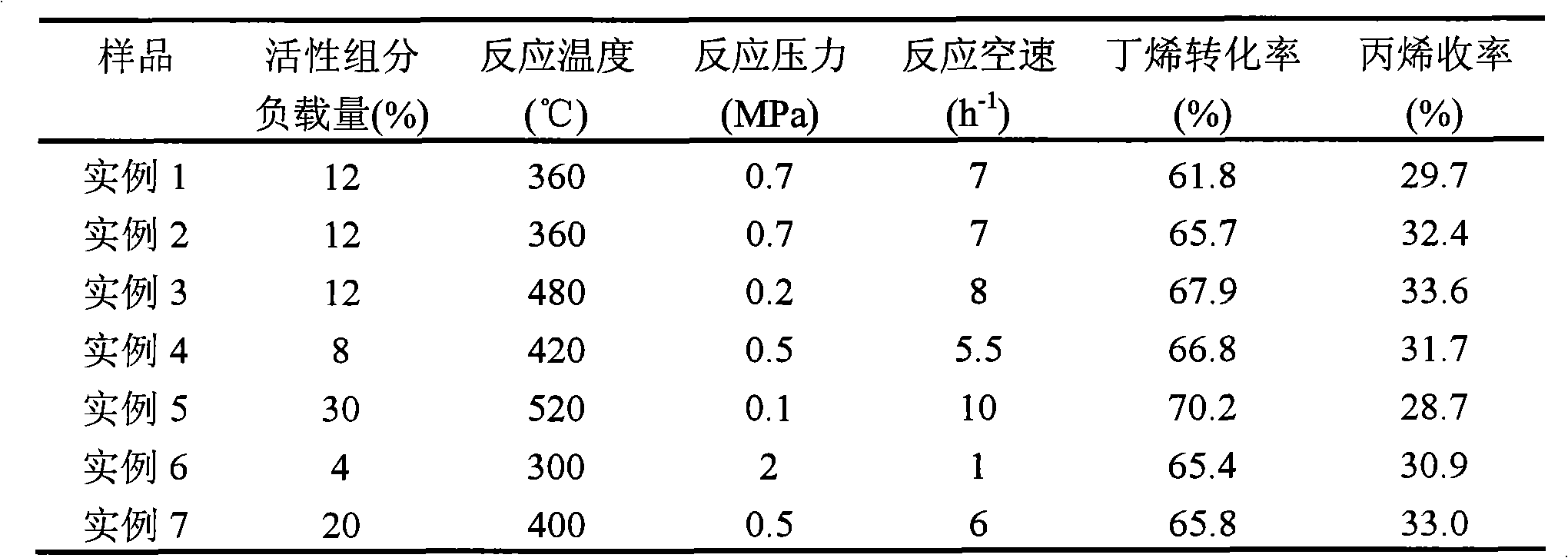

[0022] Preparation of disproportionation catalyst: put 20 kg of chromatography silica gel and 2 kg of Tianqing powder into a kneader, stir for a period of time, add 2.9 kg of active components of ammonium metatungstate and 1.5 kg of silica sol, and add a certain amount of Ionized water, after stirring for 30 minutes, put it into the extruder and extrude the strips to obtain the finished product. After drying, the catalyst WO was calcined in an air atmosphere 3 / SiO 2 , the calcination temperature is 550° C., the calcination time is 4 hours, and the prepared active component is 12 parts by weight.

[0023] In the fixed bed reactor, the composition of the reaction raw material C4 is 37.5% butane, 5.4% butene-1 and 57.1% butene-2, the reaction temperature is 360°C, the reaction pressure is 0.7MPa, the C4 Mass space velocity is 7 hours -1 . The evaluation results of the catalysts are shown in Table 1.

Embodiment 2

[0025] According to the various steps in Example 1, changing the active component is 1.4 kilograms of ammonium metatungstate and 2.1 kilograms of ammonium dimolybdate, the weight ratio of tungsten oxide and molybdenum oxide in the obtained catalyst is 1, the weight of active component The number of copies is 12, and the evaluation results are shown in Table 1.

Embodiment 3

[0027] According to each step in embodiment 1, change the active component to be 1.4 kilograms of ammonium metatungstate and 1.2 kilograms of ammonium perrhenate, the weight ratio of tungsten oxide and molybdenum oxide in the obtained catalyst is 1, the weight of active component The number of parts is 12 parts, the reaction temperature is changed to 480°C and the reaction pressure is 0.2MPa, and the mass space velocity of C4 is 8 hours -1 , and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com