Production of low-carbon olefine and arene

A technology for low-carbon olefins and aromatics, applied in the field of catalytic conversion, can solve the problems of moving reforming catalysts, complex regeneration process, inability to produce low-carbon olefins and aromatics at the same time, and low propylene yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

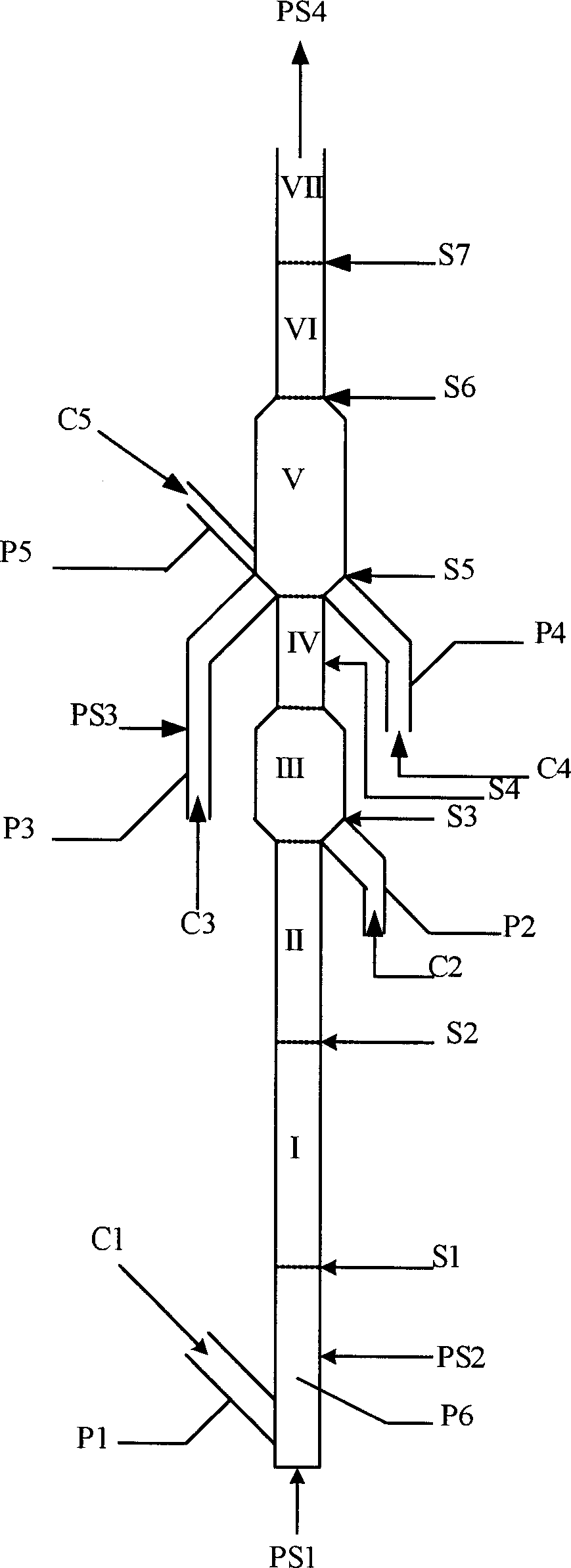

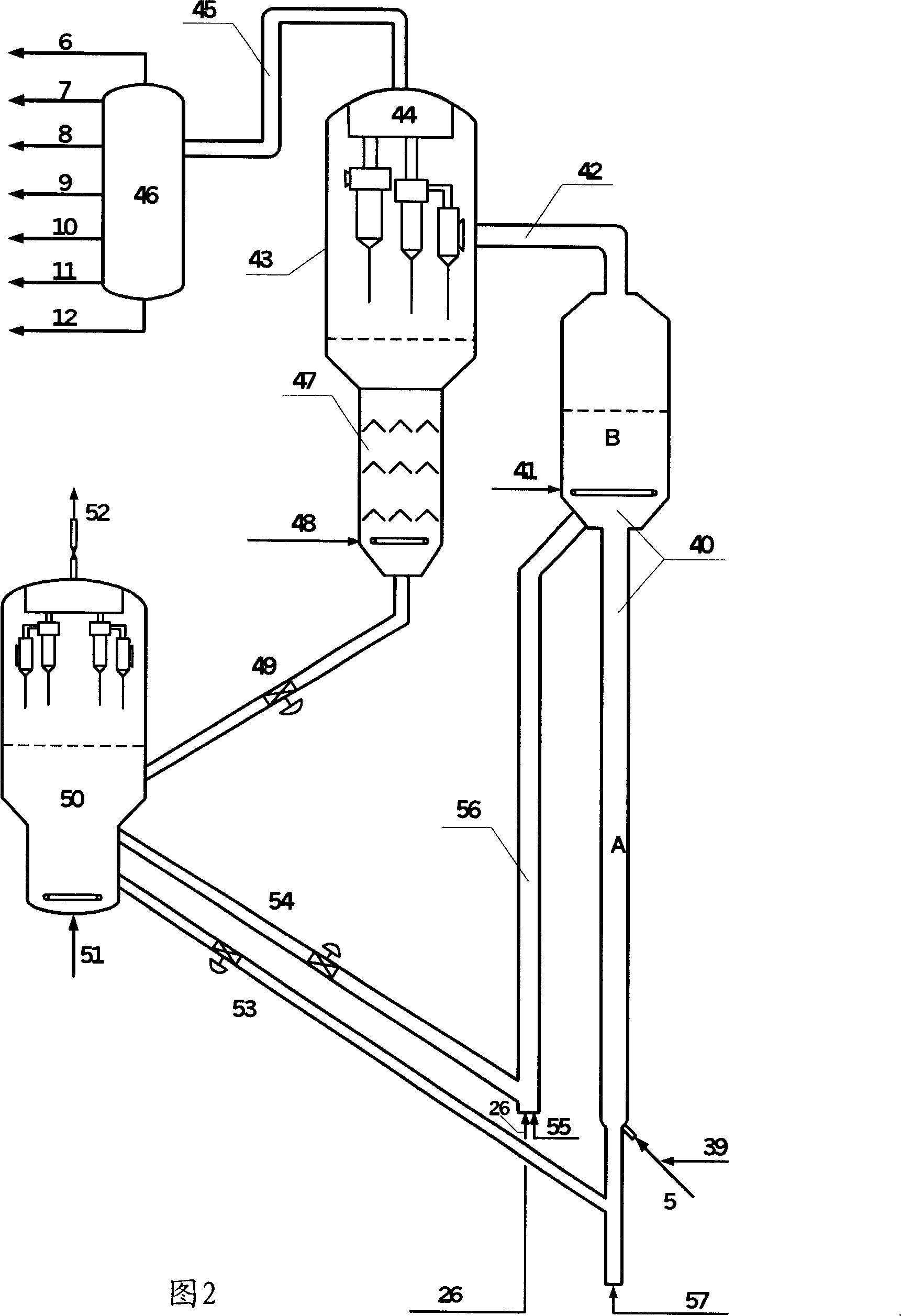

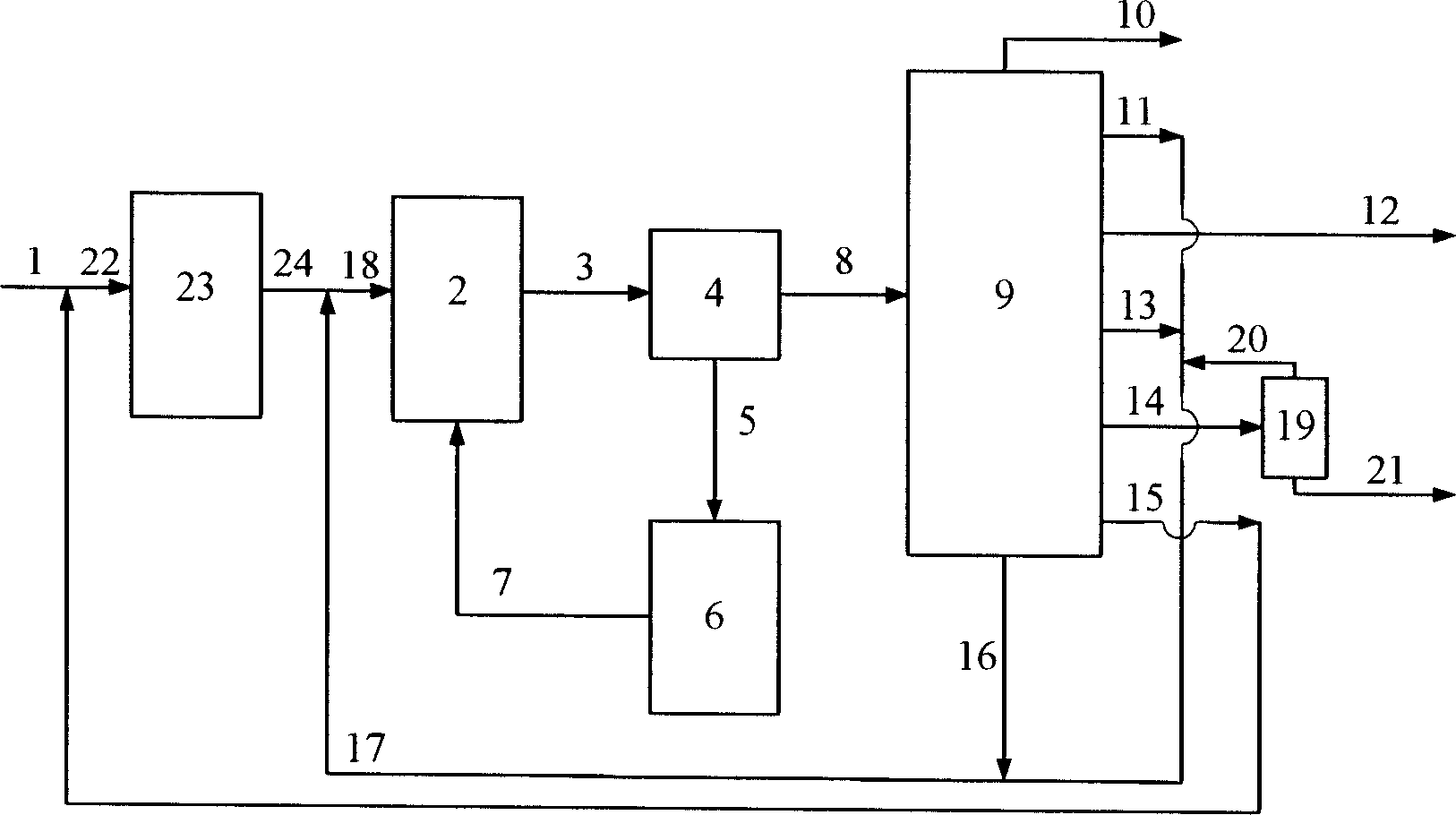

[0044] A method for producing light olefins and aromatics provided by the invention comprises:

[0045] The raw material is in contact with the catalytic cracking catalyst at a temperature of 400°C-800°C and a weight hourly space velocity of 0.1h -1 -750h -1 Under the condition of reaction, the reaction is carried out in at least two reaction zones, the reaction temperature of at least one reaction zone in the reaction zone downstream of the first reaction zone is higher than the reaction temperature of the first reaction zone, and its weight hourly space velocity is lower than The weight hourly space velocity of the first reaction zone separates the raw catalyst and reaction oil gas, the raw catalyst is returned to the reactor after regeneration, and the reaction oil gas is separated to obtain the target products of low-carbon olefins and aromatics.

[0046] The method will be described in detail in five parts below.

[0047] 1. Raw materials

[0048] The raw materials in ...

Embodiment approach 2

[0082] Another method for producing light olefins and aromatics provided by the present invention includes:

[0083] (1) The raw material oil and the optional recycle material first enter the catalytic hydrogenation unit, and contact with the hydrogenation catalyst and hydrogen, at a hydrogen partial pressure of 3.0MPa-20.0MPa, a reaction temperature of 300°C-450°C, and a hydrogen-to-oil volume ratio of 300v / v-2000v / v, volumetric space velocity 0.1h -1 -3.0h -1 react under certain conditions, separate the reaction effluent to obtain hydrogenated oil, and recycle the hydrogen;

[0084] (2) The oil produced by hydrogenation is in contact with the catalytic cracking catalyst at a temperature of 400°C-800°C and a weight hourly space velocity of 0.1h -1 -750h -1 Under the condition of reaction, the reaction is carried out in at least two reaction zones, the reaction temperature of at least one reaction zone in the reaction zone downstream of the first reaction zone is higher th...

Embodiment approach 3

[0096] The third method for producing light olefins and aromatics provided by the present invention includes:

[0097] (1) The raw material oil is in contact with hydrogen gas and hydrotreating catalyst, at a hydrogen partial pressure of 3.0MPa-20.0MPa, a reaction temperature of 300°C-450°C, a hydrogen-oil volume ratio of 300v / v-2000v / v, and a volumetric space velocity of 0.1h -1 -3.0h -1 Under the condition of 2 、CH 4 , hydrogenation C 2 °-C 4 °, hydrogenated naphtha, hydrogenated products, hydrogen recycling;

[0098] (2) The hydrogenation product of step (1) is contacted with the catalytic cracking catalyst at a temperature of 400°C-800°C and a weight hourly space velocity of 0.1h -1 -750h -1 Under the condition of reaction, the reaction is carried out in at least two reaction zones, the reaction temperature of at least one reaction zone in the reaction zone downstream of the first reaction zone is higher than the reaction temperature of the first reaction zone, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com