Device and method for detecting leakage of seal chamber by infrared imaging technology

A technology for detecting and sealing a cavity is applied in the field of devices that use infrared imaging technology to detect the leakage of a sealed cavity, and can solve the problems of complex process, large influence of environmental temperature on detection results, and difficulty in detecting leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

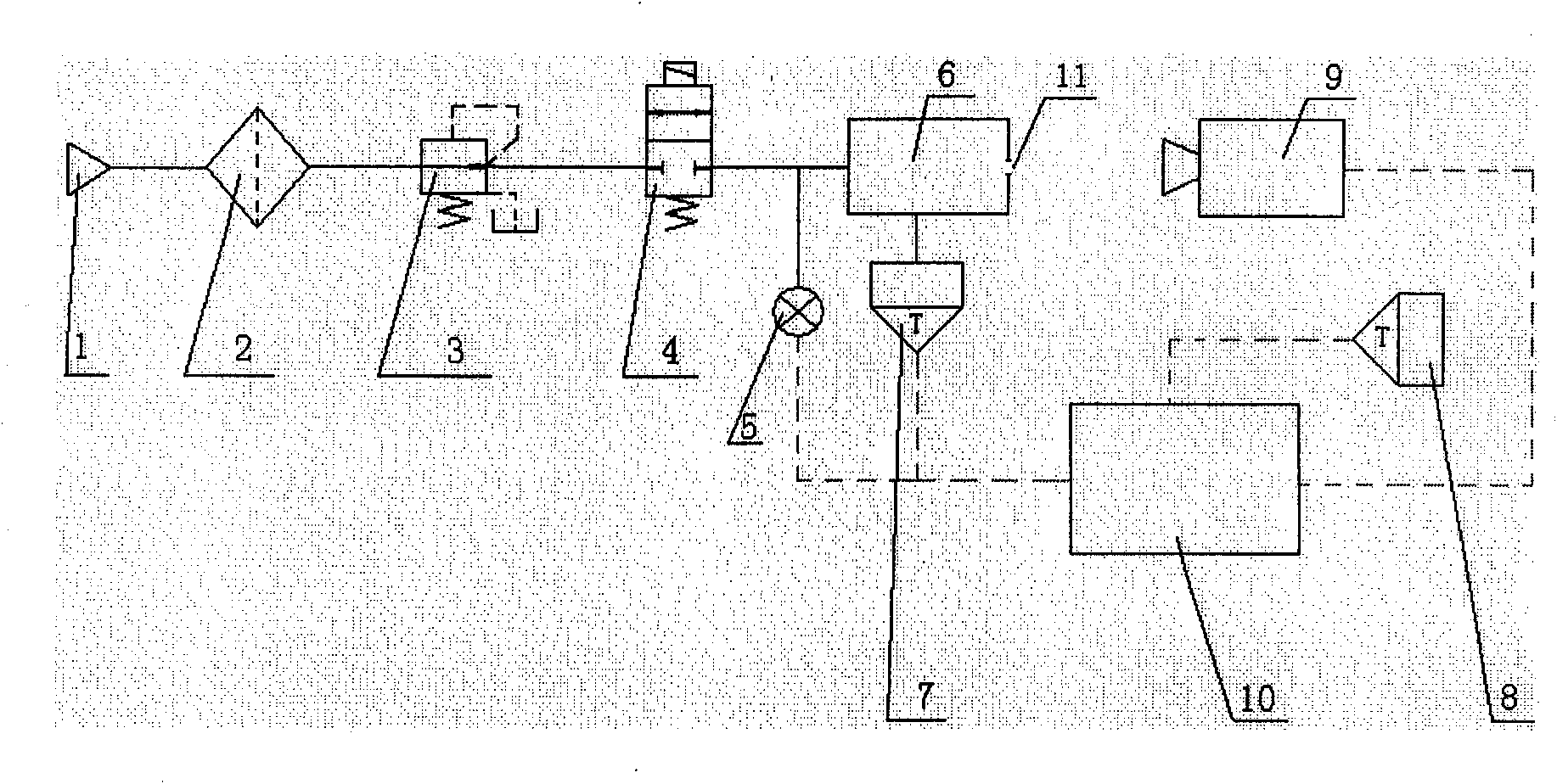

[0063] A device for detecting leakage of a sealed cavity using infrared imaging technology, comprising a gas source 1, a filter 2, a pressure regulating valve 3, a solenoid valve 4, a pressure sensor 5, a measured cavity 6, temperature sensors A 7, and a temperature sensor B8 , an infrared thermal imager 9 and a control system 10, the measured cavity 6 has a leak hole 11; the gas source 1, the filter 2, the pressure regulating valve 3, the solenoid valve 4 and the measured cavity 6 are connected in series through pipelines, and the pressure The sensor 5 is set on the pipeline between the solenoid valve 4 and the measured cavity 6, the measured cavity 6 and the control system 10 are respectively provided with a temperature sensor A7 and a temperature sensor B8, a pressure sensor 5, a temperature sensor A7, a temperature sensor B8 and the infrared camera 9 are respectively connected with the control system 10 through wires.

[0064] The method of using infrared imaging technolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com