Method for butylenes double-bond isomerization

A technology for double bond isomerization and butene, which is used in isomerization to produce hydrocarbons, organic chemistry, etc., can solve the problems of poor catalyst stability, low yield and selectivity of target products, and short life, and achieve good catalytic activity. , The effect of good product selection performance and shortened regeneration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0017] According to the molar ratio of silicon to aluminum SiO 2 / Al 2 o 3 Configure a slurry containing silicon, aluminum, template (n-butylamine) and water at a ratio of 200, and the molar ratio of the raw materials is 150 SiO 2 :Al 2 o 3 : 50 n-butylamine: 17OH-: 200NaCl: 6300H 2 O was stirred at room temperature for 15 hours. Then crystallize at a temperature of 140° C. for 50 hours, and then wash, dry and roast the crystallization solution to obtain ZSM-5 molecular sieve. Add 50 grams of ZSM-5 molecular sieves to 87 grams of 40% (weight) silica gel, mix, extrude, dry at 130°C, and roast at 430°C to prepare a ZSM-5 catalyst.

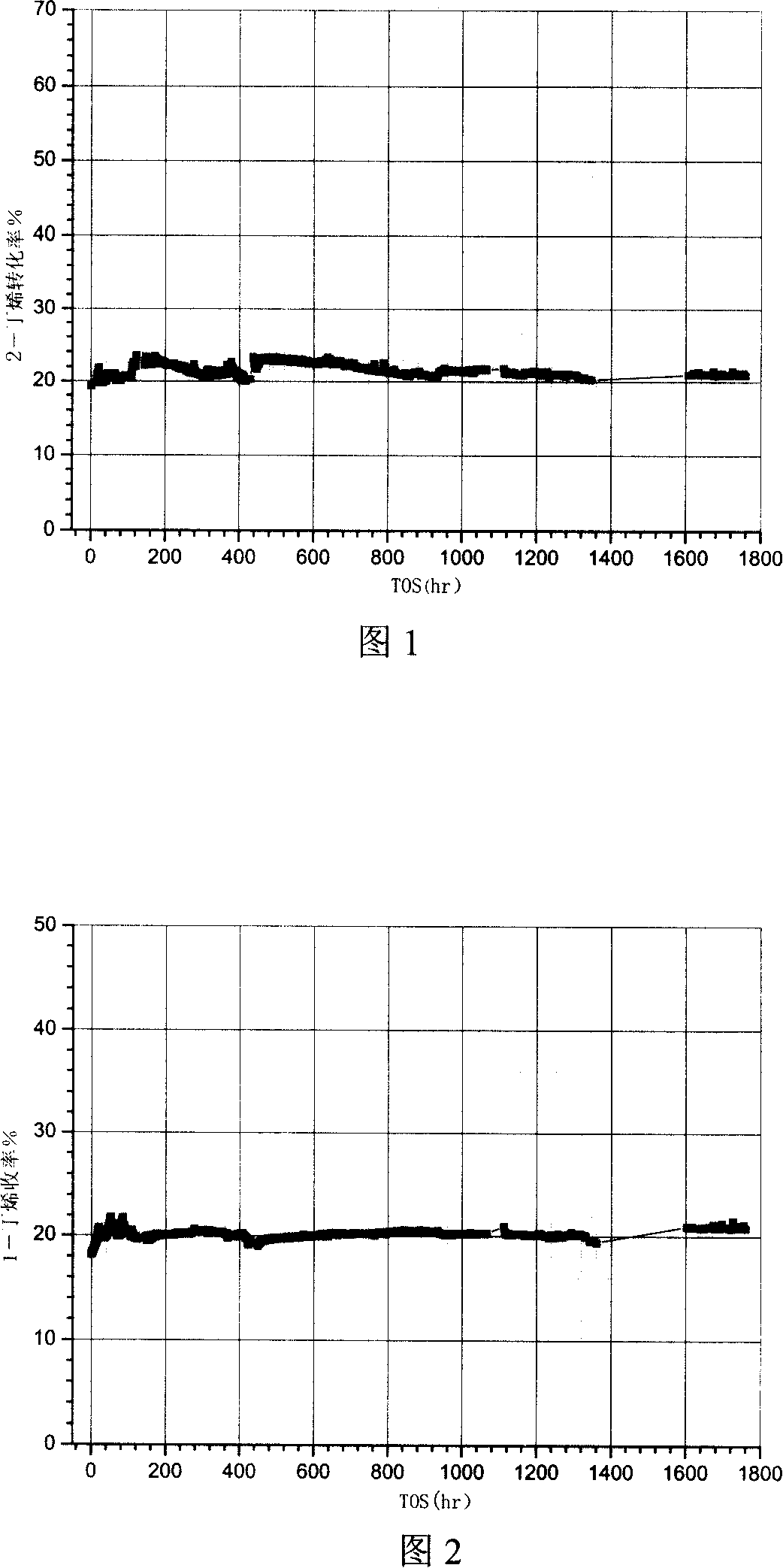

[0018] The above-mentioned ZSM-5 molecular sieve catalyst is packed into a fixed-bed reactor, and the refinery raffinate II is used as a raw material (n-butane 17.8%, cis-2-butene 22.2%, trans-2-butene 60%), 3 hours at airspeed -1 , the pressure is normal pressure, the reaction results of isomerization of butene-2 to butene-1 at different r...

Embodiment 11~20

[0022] According to each step of embodiment 1, silicon aluminum molar ratio SiO is obtained 2 / Al 2 o 3 Be the ZSM-5 type molecular sieve catalyst of 450, adopt refinery raffinate II to be raw material (n-butane 17.8%, cis-2-butene 22.2%, trans-2-butene 60%), at a temperature of 320 hours -1 , under the condition of 0.1MPa pressure, the reaction results of isomerization of butene-2 to butene-1 under different reaction space velocity conditions are shown in Table 2:

[0023] Table 2

[0024] serial number

Embodiment 21

[0026] According to the various steps and operating conditions of Example 1, the silicon-aluminum molar ratio SiO 2 / Al 2 o 3 ZSM-5 molecular sieve catalyst of 50, using pure butene-1 as raw material, at a temperature of 100°C and a space velocity of 2 hours -1 , under the condition of 0.1 MPa, the reaction result of isomerization of butene-1 to butene-2: the conversion rate of butene-1 is 92.1.3%, and the yield of butene-2 is 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com