A constant-temperature difference and variable-flow hydraulic equilibrium adjusting method and system

A technology of hydraulic balance and adjustment method, applied in heating system, high-efficiency adjustment technology, heating method, etc., can solve the problems of thermal imbalance, hydraulic imbalance of heating system, failure to meet user indoor heating standards, etc., to ensure heating effect, reduce energy consumption in transmission and distribution, and achieve good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

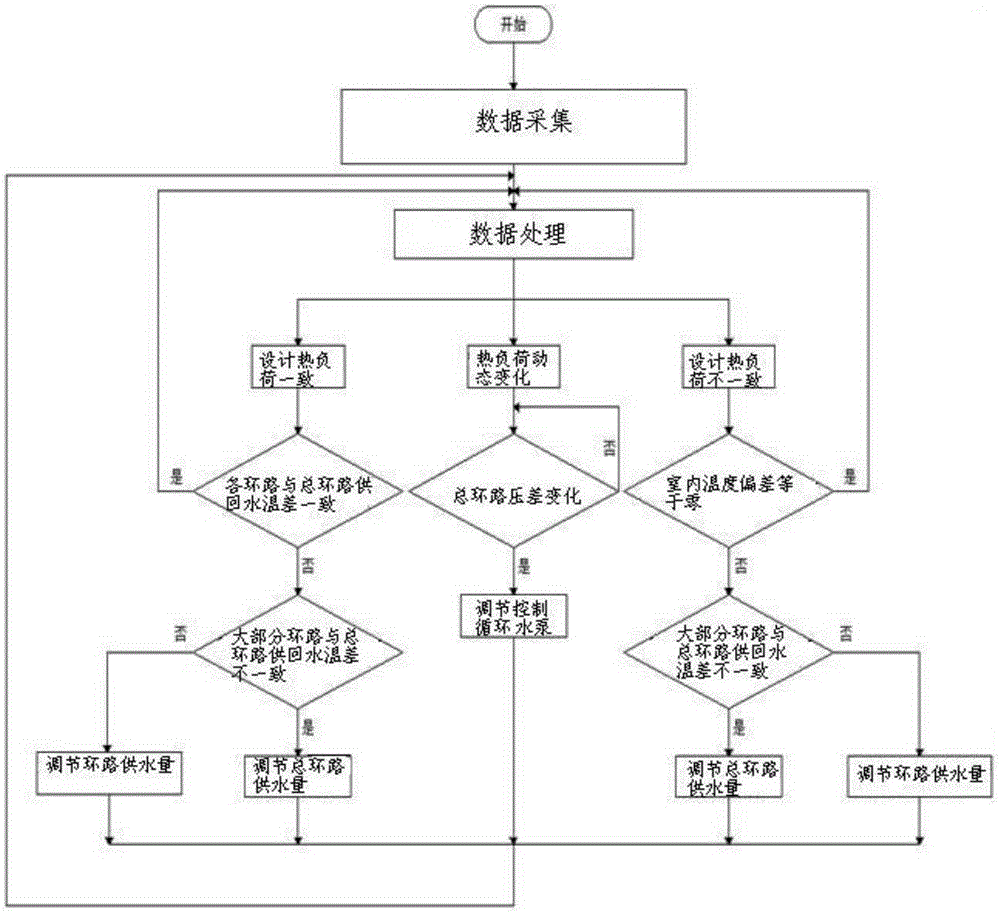

[0034] Such as figure 1 As shown, the hydraulic balance adjustment method of isothermal difference and variable flow provided by the embodiment of the present invention includes the following steps:

[0035] S1. Data collection: the indoor temperature t of users on each loop s , The water supply temperature t of the total loop g , return water temperature t of each loop i and return water temperature t of the total loop h Collect the data parameters of the pressure difference Δp between the water supply pipe and the return pipe of the total loop;

[0036] S2. Data processing: calculate the room temperature deviation Δt of users on each loop s , supply and return water temperature difference Δt of the total loop and supply and return water temperature difference Δt of each loop i ;

[0037] S3, analysis and comparison: analyze and compare the data parameters collected in step S1 and the data results obtained in step S2, and obtain the required control amount of the total ...

Embodiment 2

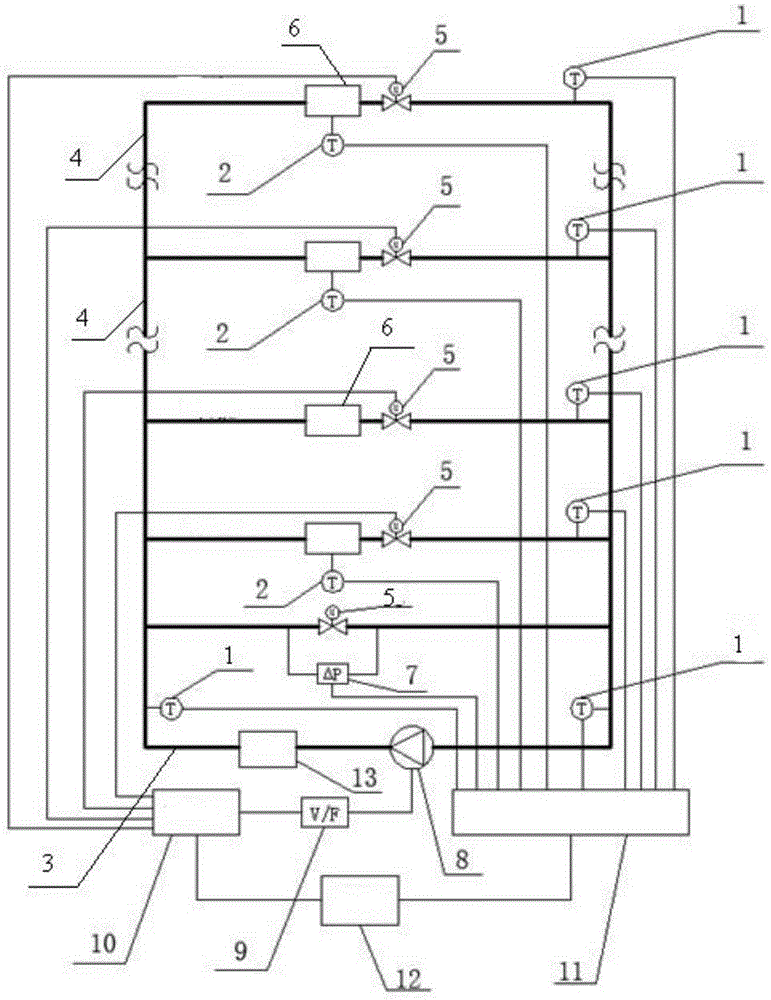

[0048] Such as figure 2 As shown, the present invention also provides a hydraulic balance regulating system with constant temperature difference and variable flow rate, including a total loop 3 and several loops 4, several loops 4 are arranged in parallel with the total loop 3 respectively, and each loop 4 There are electric control valves 5 and water temperature sensors 1 on the loop 4, room temperature sensors 2 are installed in the room of the user 6 on the loop 4, water temperature sensors 1 are installed on the water supply pipe and the return pipe of the total loop 3, and the The water supply pipe is connected to one end of the differential pressure sensor 7, and the other end of the differential pressure sensor 7 is connected to the return pipe of the total loop 3; it also includes a control device, one end of which is connected to the electric regulating valve 5, and the other end is connected to the water temperature sensor 1, The room temperature sensor 2 and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com