Method for prolonging lifetime of carriers of silicon carbide epitaxial layer

A technology of carrier lifetime and epitaxial layer, which is applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of SiC epitaxial wafer production capacity decline, etc., to eliminate carbon vacancies, increase growth rate, and improve The effect of carrier lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

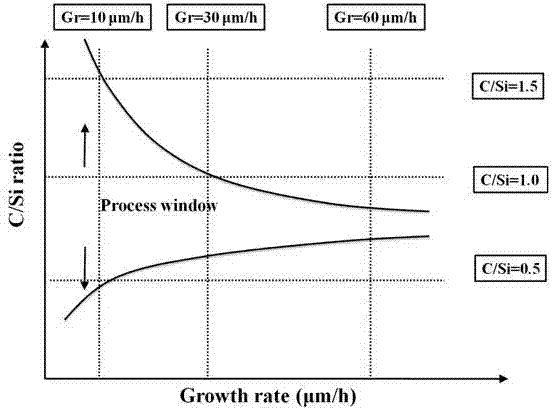

Method used

Image

Examples

Embodiment

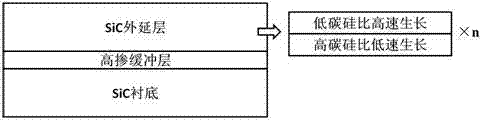

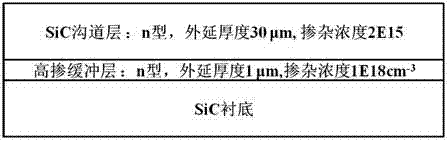

[0044] to grow image 3 The specific method of the silicon carbide epitaxial structure shown:

[0045] (1) Select a silicon carbide substrate with a silicon surface that is 4° to the direction and place the substrate in the graphite base of the reaction chamber;

[0046] (2) Use argon to replace the gas in the reaction chamber several times, then introduce hydrogen into the reaction chamber, gradually increase the flow rate of hydrogen to 100L / min, set the pressure of the reaction chamber to 100mbar, and gradually raise the temperature of the reaction chamber to 1600°C ;

[0047] (3) After reaching the set temperature, open the intake valves of silane, propane and nitrogen, and put all kinds of sources into the exhaust gas path, set the flow rate of silane to 25 sccm, propane flow rate to 7.5 sccm, nitrogen flow rate to 500 sccm, and keep the other The parameters remain unchanged, and the silicon carbide substrate is subjected to in-situ hydrogen etching for 10 minutes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com