Re-melting slag system used for electroslag re-melting high-titanium low-aluminum type steel type and smelting technique

A technology of electroslag remelting and remelting slag, which is applied in the field of electroslag metallurgy and can solve problems such as uneven composition of aluminum and titanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

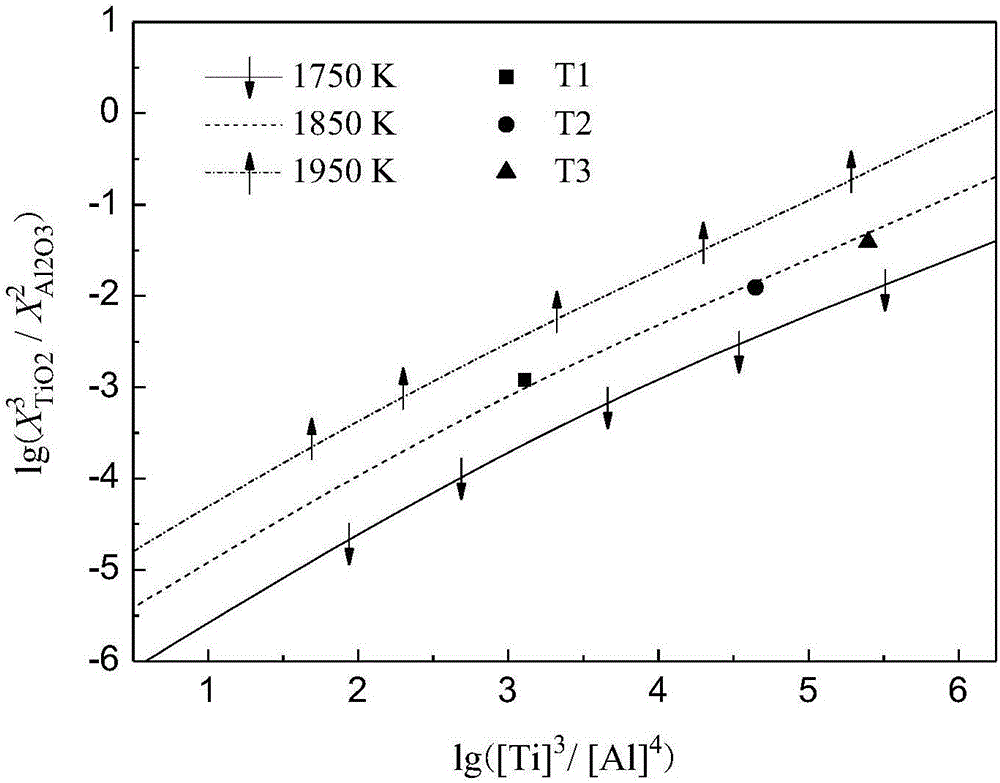

[0027] For 1Cr21Ni5Ti stainless steel, using the method established by the present invention, according to the composition characteristics of the consumable electrode, the composition of the base slag is determined to be: CaF 2 :Al 2 o 3 :CaO:MgO=65:20:5:10. Add 2%, 5%, and 10% TiO to the base slag respectively 2 MoSi 2 The slag-gold balance experiment at 1577°C in the resistance furnace is recorded as T1, T2, and T3 respectively. Using the slag molecular ion coexistence theory to calculate the concentration, combined with the Al, Ti in the steel and Al in the slag in the equilibrium state in the slag-gold balance experiment results 2 o 3 and TiO 2 content, activity coefficient term Amendment, using formula (2) to get TiO 2 content, such as figure 2 shown.

[0028] When the Ti content in the electroslag ingot is required to be 0.60 and the Al content to be 0.04, the TiO in the primary slag at the liquidus line of the steel grade is 1477°C can be calculated through ...

Embodiment 2

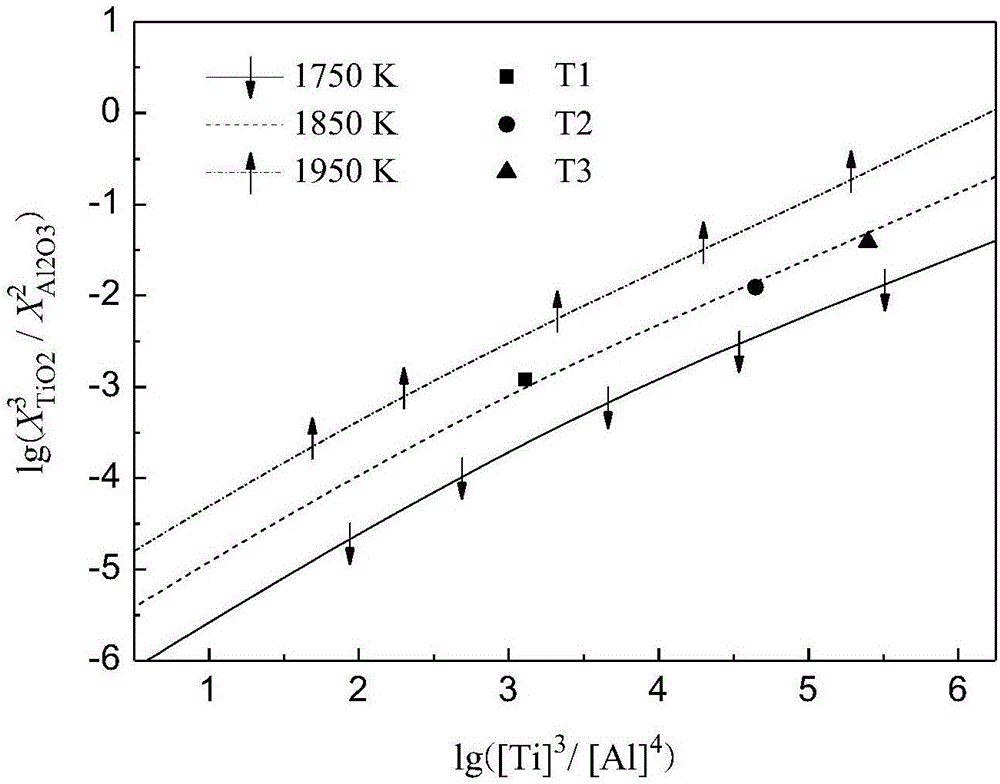

[0032] For 1Cr21Ni5Ti stainless steel, adopt the method established by the present invention, according to the composition characteristics of the consumable electrode, determine that the base slag composition is CaF 2 :Al 2 o 3 :CaO:MgO=65:20:5:10. Add 2%, 5%, and 10% TiO to the base slag respectively 2 MoSi 2 The slag-gold balance experiment at 1577°C in the resistance furnace is recorded as T1, T2, and T3 respectively. Using the slag molecular ion coexistence theory to calculate the concentration, combined with the Al, Ti in the steel and Al in the slag in the equilibrium state in the slag-gold balance experiment results 2 o 3 and TiO 2 content, activity coefficient term Amendment, using formula (2) to get TiO 2 content, such as image 3 shown.

[0033] When the Ti content in the electroslag ingot is required to be 0.45 and the Al content is 0.06, the TiO in the primary slag at the liquidus line of the steel grade is 1477°C is calculated through this figure. 2 Th...

Embodiment 3

[0037] For 1Cr18Ni9Ti stainless steel, adopt the method established by the present invention, according to the composition characteristics of the consumable electrode, determine that the base slag composition is CaF 2 :Al 2 o 3 :CaO:MgO=65:25:0:10. Add 1.5%, 2.5%, 5.5% TiO to the base slag respectively 2 MoSi 2 The slag-gold balance experiment at 1577°C in the resistance furnace is recorded as T1, T2, and T3 respectively. Using the slag molecular ion coexistence theory to calculate the concentration, combined with the Al, Ti in the steel and Al in the slag in the equilibrium state in the slag-gold balance experiment results 2 o 3 and TiO 2 content, activity coefficient term Amendment, using formula (2) to get TiO 2 content, such as Figure 4 shown.

[0038] When the Ti content in the electroslag ingot is required to be 0.35 and the Al content to be 0.05, the TiO in the primary slag at the liquidus line of the steel grade is 1483°C is calculated from the figure. 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com