Split type micro extensometer for measuring tensile deformation of small in-situ tension tester

An in-situ stretching and stretching deformation technology, applied in the direction of electric/magnetic solid deformation measurement, measuring devices, electromagnetic measuring devices, etc., can solve the problem that the extensometer cannot be integrated and obtain the stretching deformation of the material, and achieve a compact structure, The effect of small size and accurate test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

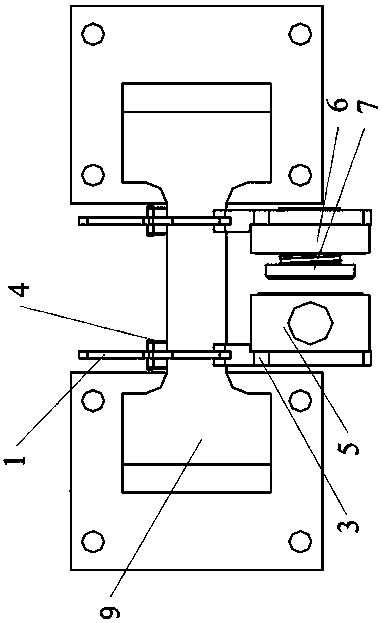

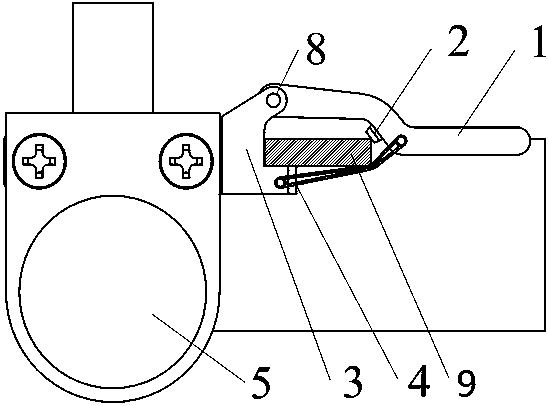

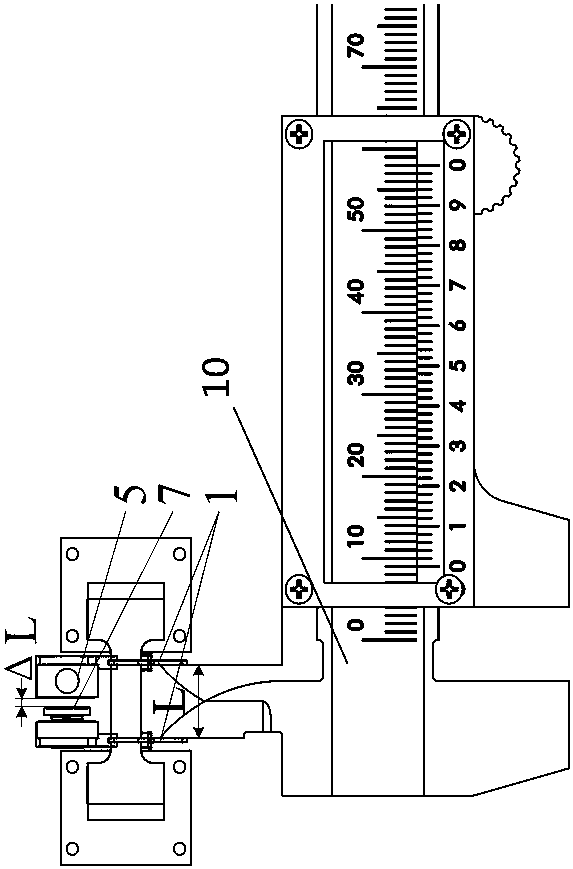

[0015] see Figure 1 to Figure 3 As shown, the split-type miniature extensometer of the present invention for measuring the tensile deformation of a small in-situ extensometer includes a clamping clip 1, a blade 2, a fixing clip 3, a rubber band 4, a capacitive displacement sensor 5, and a measuring plate fixing frame 6. The spiral measuring plate 7 and the rotating shaft 8, the fixed clamp 3 is close to the side of the sample 9 to ensure the installation perpendicularity of the extensometer and the sample 9, the clamp 1 with the blade 2 is installed to clamp the sample 9, and fix The clamp 3 is rotatably connected with the clamping clamp 1 through the rotating shaft 8 . The rubber band 4 binds the thin rod on the fixing clamp 3 and the thin rod on the clamping clamp 1 tightly, and the tension provided by the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com