Method for quickly detecting self-discharge consistency of lithium ion battery and test device

A lithium-ion battery and testing device technology, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problem of not being able to quickly and accurately check out the battery cells, and achieve fast testing methods, accelerated self-discharge rate, and shortened cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

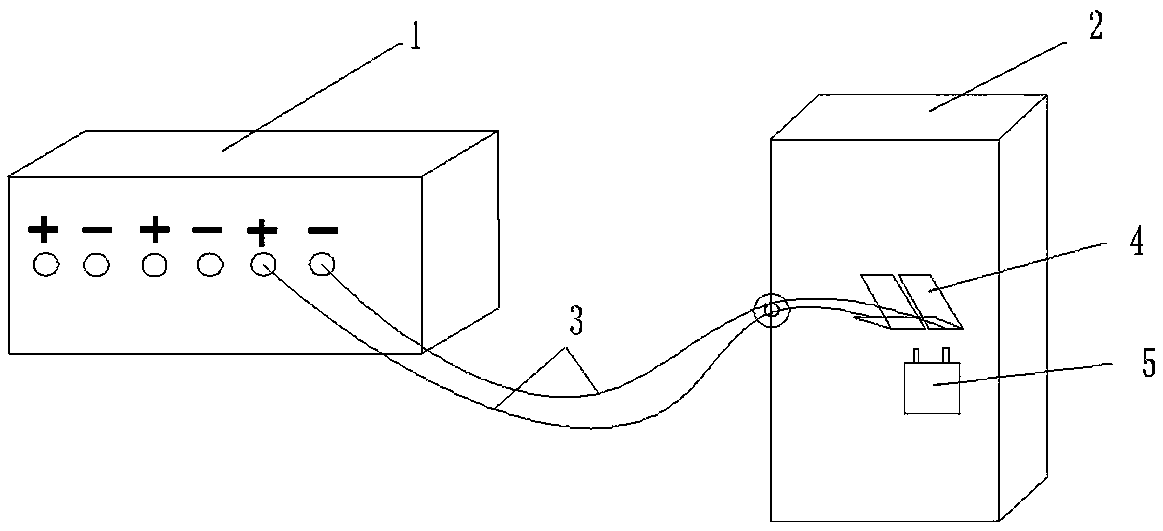

[0023] First, check to confirm that the battery cell fixture 4 provided in the oven 2 is electrically connected to the positive and negative electrodes of the battery charging and discharging cabinet 1, and the battery cell fixture 4 is correspondingly clamped to the positive and negative pole ears of the lithium-ion battery cell 5 to be tested, Ten batteries can be fixed separately. Then set the charge and discharge temperature of the oven 2 to 60°C, and set the charge and discharge hold time of the battery charge and discharge cabinet 1 to 120 min.

[0024] Then, the oven 2 is powered on, and when the charging and discharging temperature in the oven is kept at 60°C, the working program of the battery charging and discharging cabinet 1 is started. Observe the change of the voltage of the battery cell 5, and record the voltage value of the battery cell.

[0025] Finally, calculate the voltage change value of the battery cell 5 before and after discharge, and sort out the cell...

Embodiment 2

[0029] First, check to make sure that the cell fixture 4 set in the muffle furnace 2 is electrically connected to the positive and negative electrodes of the Arbin electrochemical tester 1, and the cell fixture 4 is correspondingly clamped to the positive and negative electrodes of the lithium-ion cell 5 to be tested The tabs can hold ten batteries respectively. Then set the charge and discharge temperature of the muffle furnace 2 to 65°C, and the charge and discharge hold time of the Arbin electrochemical tester 1 to 150 min.

[0030] Then, the muffle furnace 2 is turned on and powered on. When the charge and discharge temperature in the muffle furnace is maintained at 65°C, the Arbin electrochemical tester 1 working program is started. The computer control terminal can observe the change of the voltage of the battery cell 5 in real time, and record the voltage value of the battery cell.

[0031] Finally, calculate the voltage change value of battery cell 5 before and after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com