Electric heating tube testing device and method

A testing device and testing method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of uninterrupted heat loss, large contact area between water surface and air, unable to reach 100 ℃ water temperature test, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

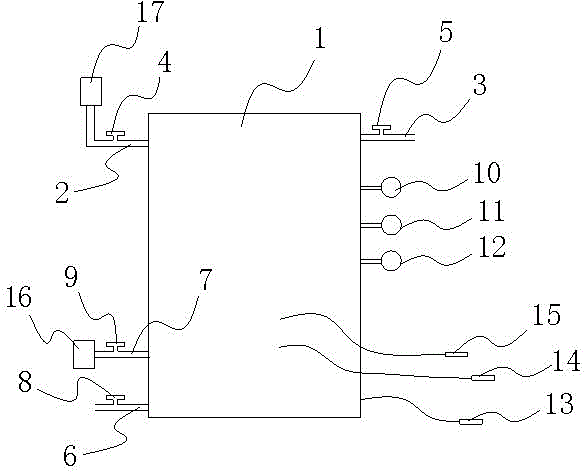

[0020] As shown in the figure (the cover is not shown in the figure), the electric heating tube testing device of this embodiment includes a metal test cylinder 1 with a movable cylinder cover, and the upper part of the test cylinder 1 is connected with a liquid inlet pipe 2 and an exhaust gas. Pipe 3, the liquid inlet pipe 2 is provided with a liquid inlet valve 4, and the exhaust pipe 3 is provided with an exhaust valve 5; the bottom of the test tube 1 is provided with a liquid discharge pipe 6 and an air intake pipe 7, and the liquid discharge pipe 6 is provided with a liquid discharge valve 8, and the air inlet pipe 7 is provided with an air inlet valve 9; the test cylinder 1 is connected with an air pressure gauge 10, a hydraulic pressure gauge 11, and a temperature gauge 12 through pipelines, and the cylinder body of the test cylinder 1 is passed through a wire The ground terminal 13 is connected, and the test cylinder 1 is provided with a withstand voltage test terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com