Simulation test device and method for coalbed methane production capacity change caused by discontinuous drainage

A simulation device and simulation test technology, applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., can solve problems affecting the productivity of coalbed methane wells, water flow distance, flow difference, free gas adsorption, etc., to improve work Efficiency and detection accuracy, automatic operation and control, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

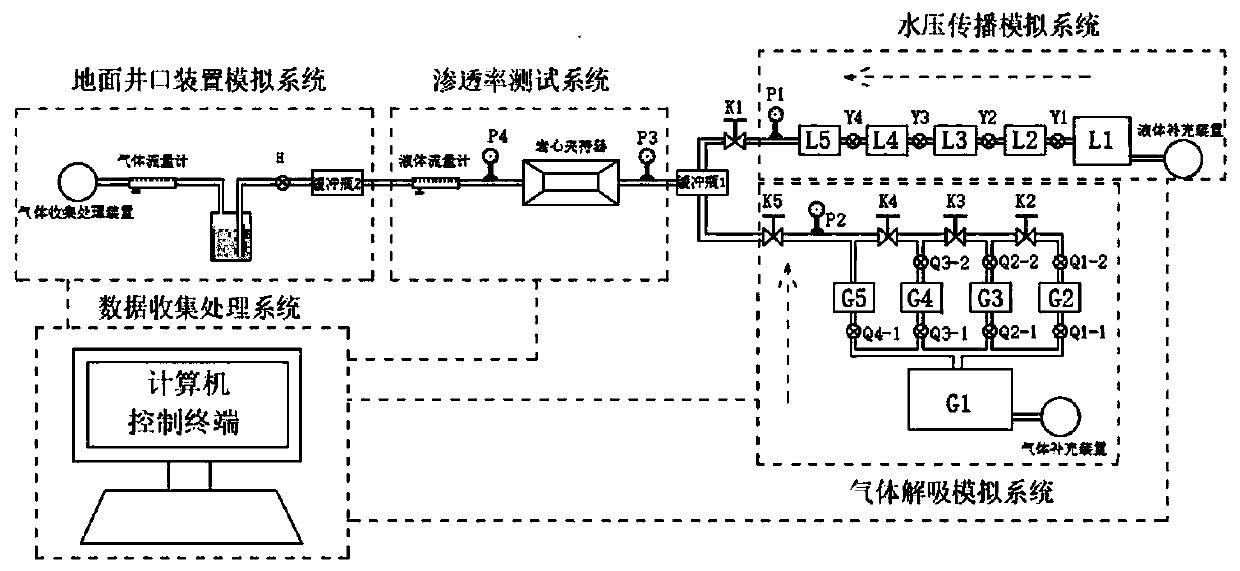

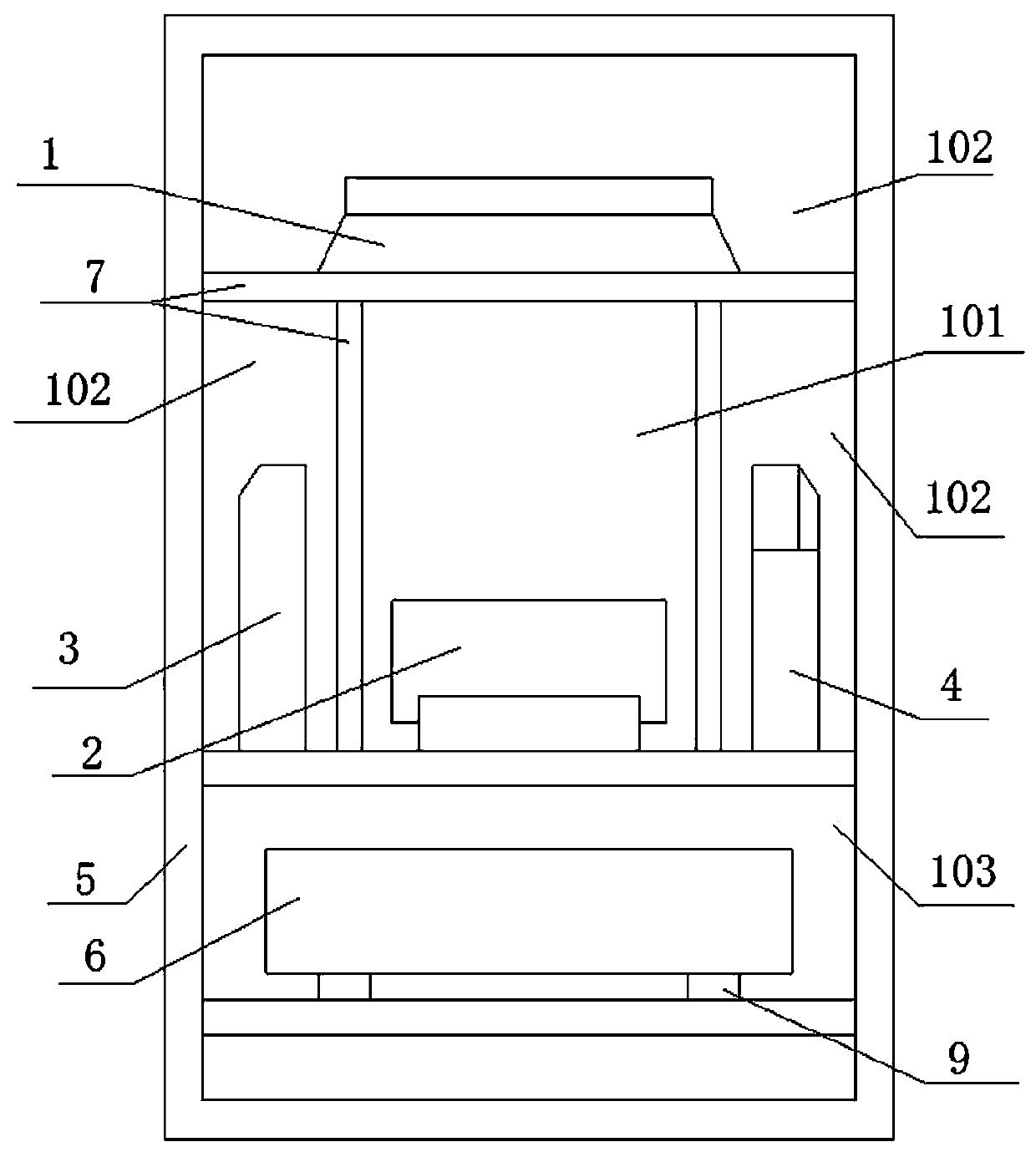

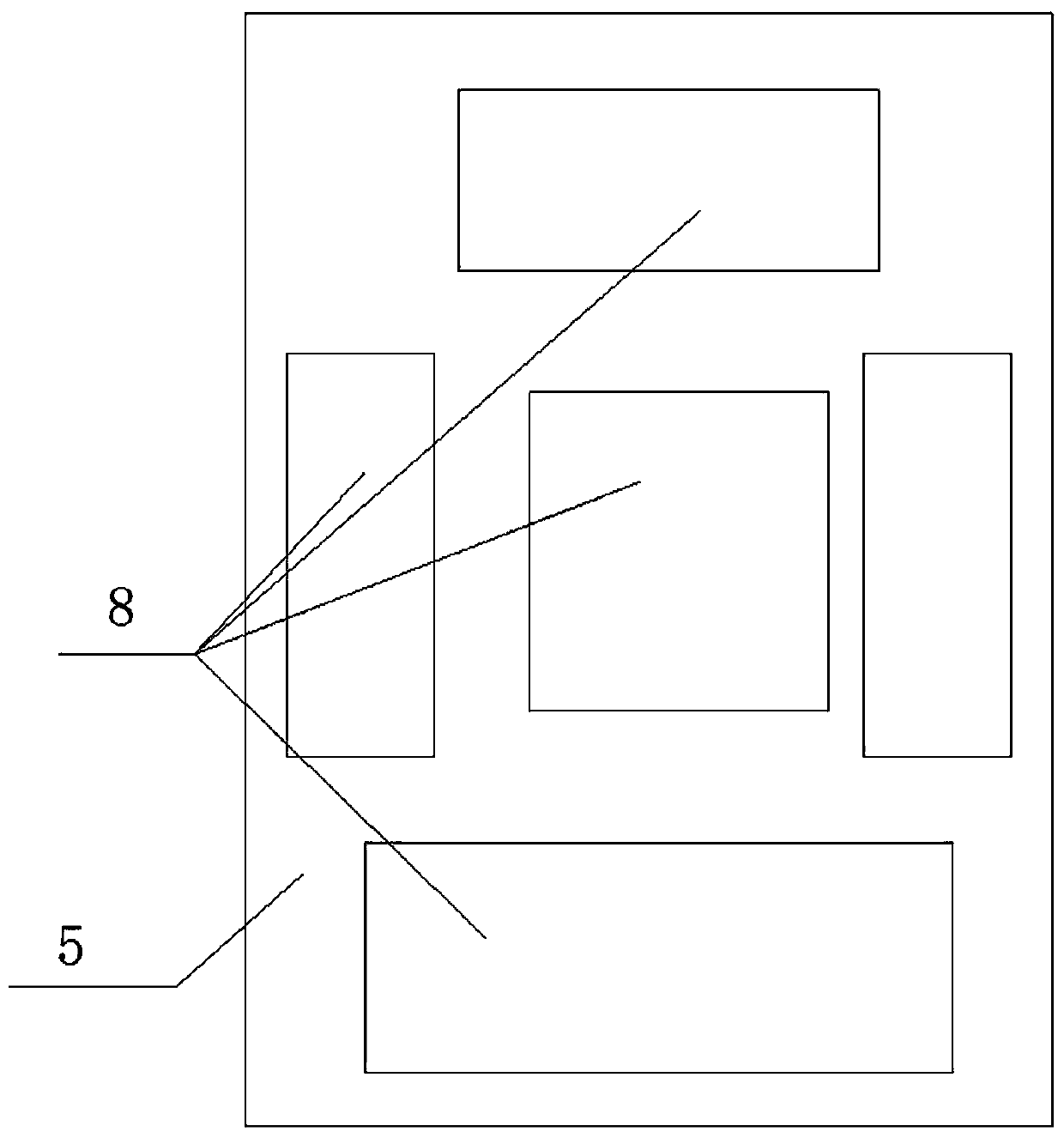

[0033] Such as figure 1 —7 The simulation test device for the change in coalbed methane production capacity caused by discontinuous drainage, including a wellhead device simulation device 1, a permeability test device 2, a water pressure propagation simulation device 3, a gas desorption simulation device 4, an experimental cabinet 5 and data acquisition The processing device 6 and the experimental cabinet 5 are airtight cavity structures with the axis and the horizontal plane vertically distributed. Several partitions 7 are evenly distributed in the experimental cabinet, and the experimental cabinet 5 is divided into an experimental detection chamber 101 and three experimental driving chambers by the partitions 7. chamber 102 and a control chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com