Analog device for on-line monitoring of dissolving gas in transformer oil and detection method thereof

A technology for transformer oil and dissolved gas, applied in the field of simulation devices, can solve the problems of large difference in oil-gas separation balance time, long time required for oil-gas separation process balance, shortening time required for oil-gas separation process balance, etc., to achieve temperature distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

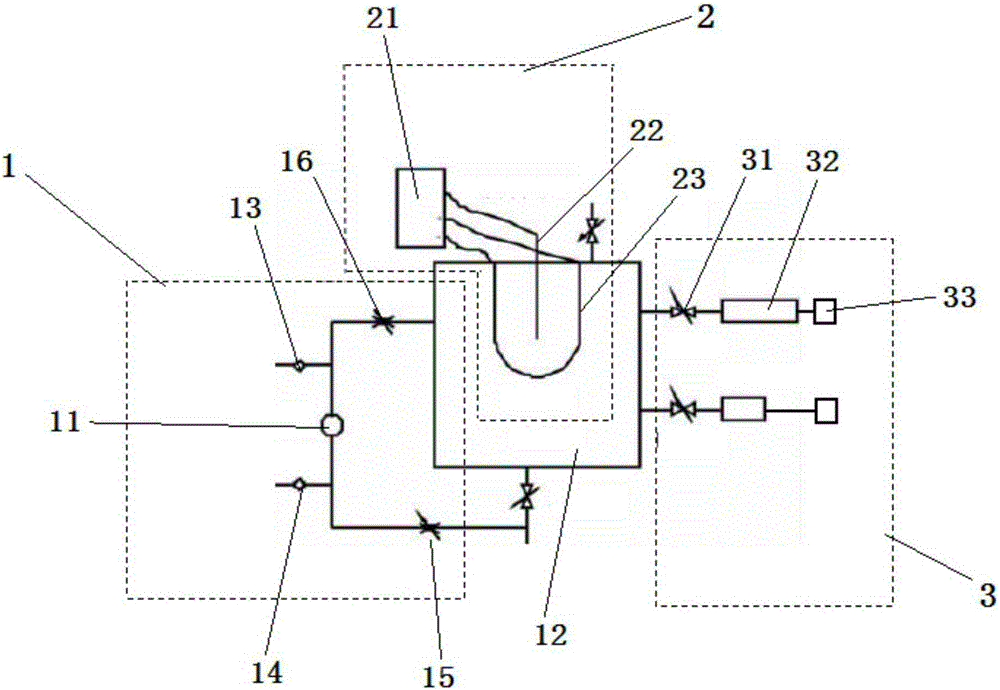

[0034] A simulation device for on-line monitoring of dissolved gas in transformer oil, its structure is as follows figure 1 As shown, it includes hydraulic circulation system 1, fuel tank temperature control system 2 and gas collection and detection system 3;

[0035]The hydraulic circulation system 1 includes a fuel tank 12 and an oil pump 11 connected by a circulation pipeline. The fuel tank 12 is an integrally formed plexiglass box with a specification of 300mm×300mm×300mm, and its wall thickness is 8mm. Insulation material, the top of the oil tank 12 is provided with an installation port matching the heating pipe 23 and the temperature sensor 22, and the installation port is provided with a sealing ring for sealing. Connected to the side of the oil tank 12, the circulation pipeline is also provided with an air injection port for injecting faulty gas into the hydraulic circulation system 1, and a flow regulating valve for adjusting the flow in the circulation pipeline. Ther...

Embodiment 2

[0044] A simulation device for online monitoring of dissolved gas in transformer oil, including a hydraulic circulation system 1, an oil tank temperature control system 2 and a gas collection and detection system 3;

[0045] The hydraulic circulation system 1 includes a fuel tank 12 and an oil pump 11 connected by a circulation pipeline. The fuel tank 12 is an integrally formed plexiglass box with a specification of 300mm×300mm×300mm, and its wall thickness is 12mm. Insulation material, the top of the oil tank 12 is provided with an installation port matching the heating pipe 23 and the temperature sensor 22, and the installation port is provided with a sealing ring for sealing. Connected to the side of the oil tank 12, the circulation pipeline is also provided with an air injection port for injecting faulty gas into the hydraulic circulation system 1, and a flow regulating valve for adjusting the flow in the circulation pipeline. There are two gas injection ports, including th...

Embodiment 3

[0054] A simulation device for online monitoring of dissolved gas in transformer oil, including a hydraulic circulation system 1, an oil tank temperature control system 2 and a gas collection and detection system 3;

[0055] The hydraulic circulation system 1 includes a fuel tank 12 and an oil pump 11 connected by a circulation pipeline. The fuel tank 12 is an integrally formed plexiglass box with a specification of 300mm×300mm×300mm, and its wall thickness is 10mm. The top of the oil tank 12 is provided with an installation port matching the heating pipe 23 and the temperature sensor 22, and a sealing ring is provided at the installation port for sealing. The end is connected to the side of the fuel tank 12, and the circulation pipeline is also provided with an injection port for injecting faulty gas into the hydraulic circulation system 1, and a flow regulating valve for adjusting the flow in the circulation pipeline. There are two injection ports, including the The first ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com