Method for rapidly testing weather resistance of titanium dioxide and application

A test method and technology for titanium dioxide, which are applied in the preparation of test samples, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve the problems affecting the weather resistance test of titanium dioxide, low data reliability, and the inability of titanium dioxide to be uniform and stable. Dispersion and other problems, to achieve the effect of no adsorption and agglomeration phenomenon, obvious change in color image, and simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

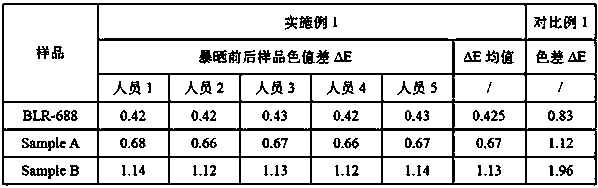

Embodiment 1

[0029] 1) The material formula for preparing the test sample is calculated in parts by weight: 100 parts of polyvinyl chloride resin, 5 parts of titanium dioxide, 3 parts of lead salt stabilizer (tribasic lead sulfate), 2 parts of chlorinated polyethylene, plasticizer ( DEHP) 1 part, light calcium carbonate 3 parts, ACR-401 1 part, paraffin 0.1 part; Add the materials in the formula to the high mixer in order, mix at 1000rpm for 15min, take it out and let it stand for 12 hours;

[0030] 2) Add the mixture obtained in step 1) into the hopper of the extruder, set the temperature of the extruder at 180°C, and extrude the sample;

[0031] 3) Cut the sample piece obtained in step 2) into a test piece of 3.5cm×8cm, and test its color value L 0 、a 0 , b 0 ;

[0032] 4) Put the test sample in a water tank (degassed tap water), isolate the air, and put it in a place exposed to direct sunlight (high temperature and clear weather at noon in summer: temperature > 35 ° C, humidity > 70%...

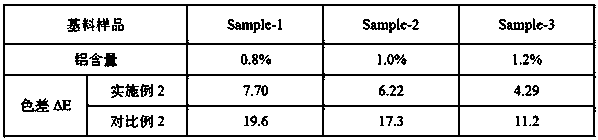

Embodiment 2

[0036] 1) The material formula for preparing the test sample is calculated in parts by weight: 100 parts of polyvinyl chloride resin, 10 parts of titanium dioxide, 10 parts of lead salt stabilizer (tribasic lead maleate), 8 parts of chlorinated polyethylene, plastic 3 parts of DOP, 20 parts of light calcium carbonate, 3 parts of ACR-4013, 1 part of paraffin; add the materials in the formula into the high mixer in order, mix at 1200rpm for 12 minutes, take it out and let it stand for 12 hours.

[0037] 2) Add the mixture obtained in step 1) into the hopper of the extruder, set the temperature of the extruder at 160°C, and extrude the sample;

[0038] 3) Cut the sample piece obtained in step 2) into a test piece of 3.5cm×10cm, and test its color value L 0 、a 0 , b 0 ;

[0039] 4) Seal the test piece with water to isolate the air and put it in the UV aging box (test conditions: 60°C, 0.78W / m 2 ); after 2 hours of exposure, test its color value L 1 、a 1 , b 1 ;

[0040] 5)...

Embodiment 3

[0043] 1) The material formula for preparing the test sample is calculated in parts by weight: 100 parts of polyvinyl chloride resin, 8 parts of titanium dioxide, 8 parts of lead salt stabilizer (dibasic lead phthalate), 5 parts of chlorinated polyethylene, 2 parts of plasticizer (DBP), 10 parts of light calcium carbonate, 2 parts of ACR-4012, 0.5 parts of paraffin; add the materials in the formula to the high mixer in order, mix at 1500rpm for 10 minutes, take it out and let it stand for 12 hours .

[0044] 2) Add the mixture obtained in step 1) into the silo of the extruder, set the temperature of the extruder at 190°C, and extrude the sample;

[0045] 3) Cut the sample piece obtained in step 2) into a test piece of 3.5cm×10cm, and test its color value L 0 、a 0 , b 0 ;

[0046] 4) Put the test piece into the xenon lamp aging box after sealing it with water and isolating the air (test conditions: 45°C, 0.51W / m 2 ); after 2 hours of exposure, test its color value L 1 、a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com