Nuclear power generator test device

A test device and generator technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of low adjustment accuracy of variable frequency units, poor time synchronization, and low accuracy of manual measurement and sampling values. Easy to query, ensure simultaneity, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

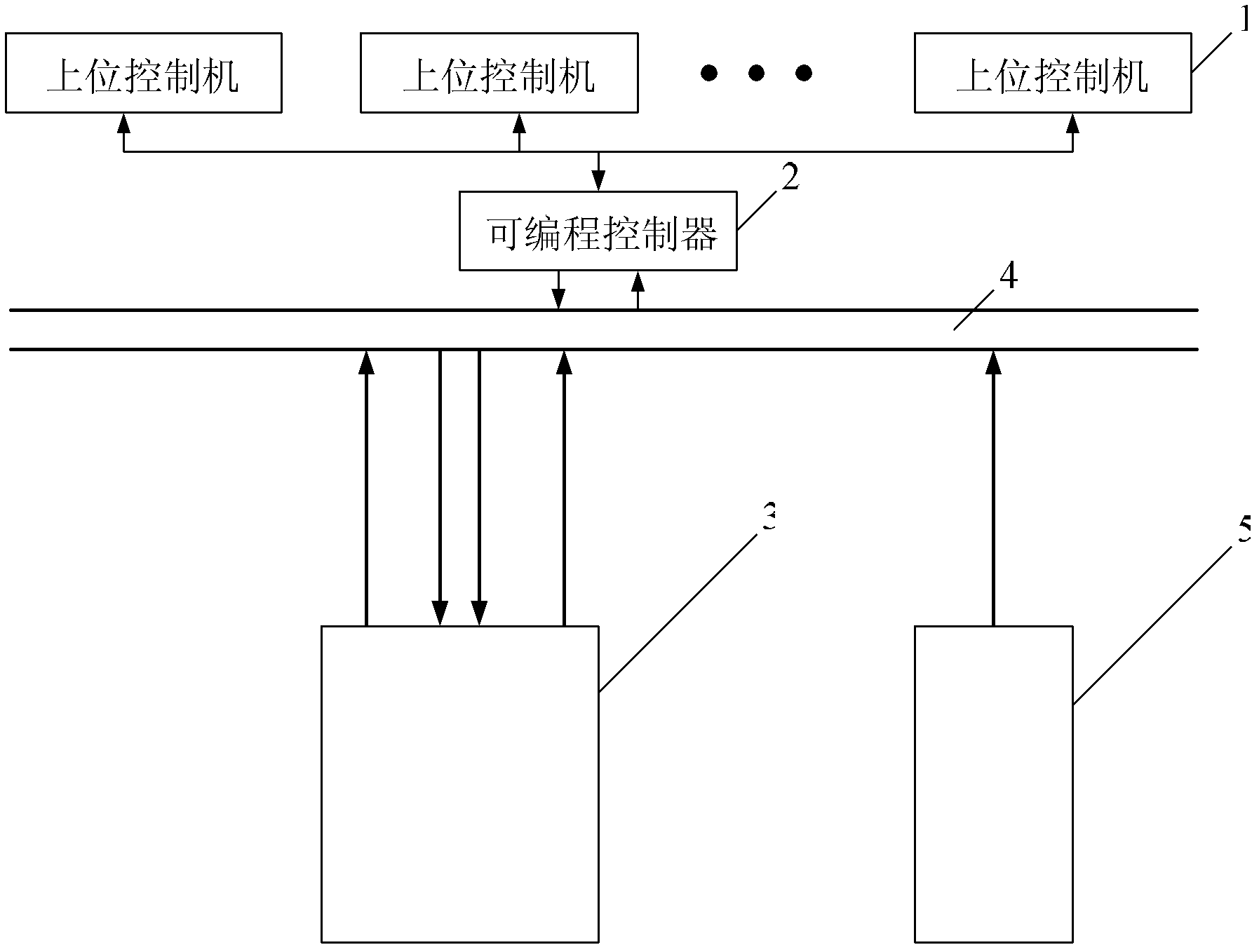

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, the nuclear power generator test device described in this embodiment, it is made up of M upper control machine 1, programmable controller 2, electrical monitoring system 3, field bus 4 and non-electrical monitoring system 5; M is positive Integer; the sampling data and control signal input and output terminals of each host controller 1 are connected to the sampling data and control signal output and input terminals of the programmable controller 2 through industrial Ethernet; the sampling data of the programmable controller 2 The data input terminal is connected with the first sampling data output terminal of the electrical monitoring system 3, the second sampling data output terminal of the electrical monitoring system 3 and the sampling data output terminal of the non-electrical monitoring system 5 through the field bus 4; the programmable control The control signal output end of the device 2...

specific Embodiment approach 2

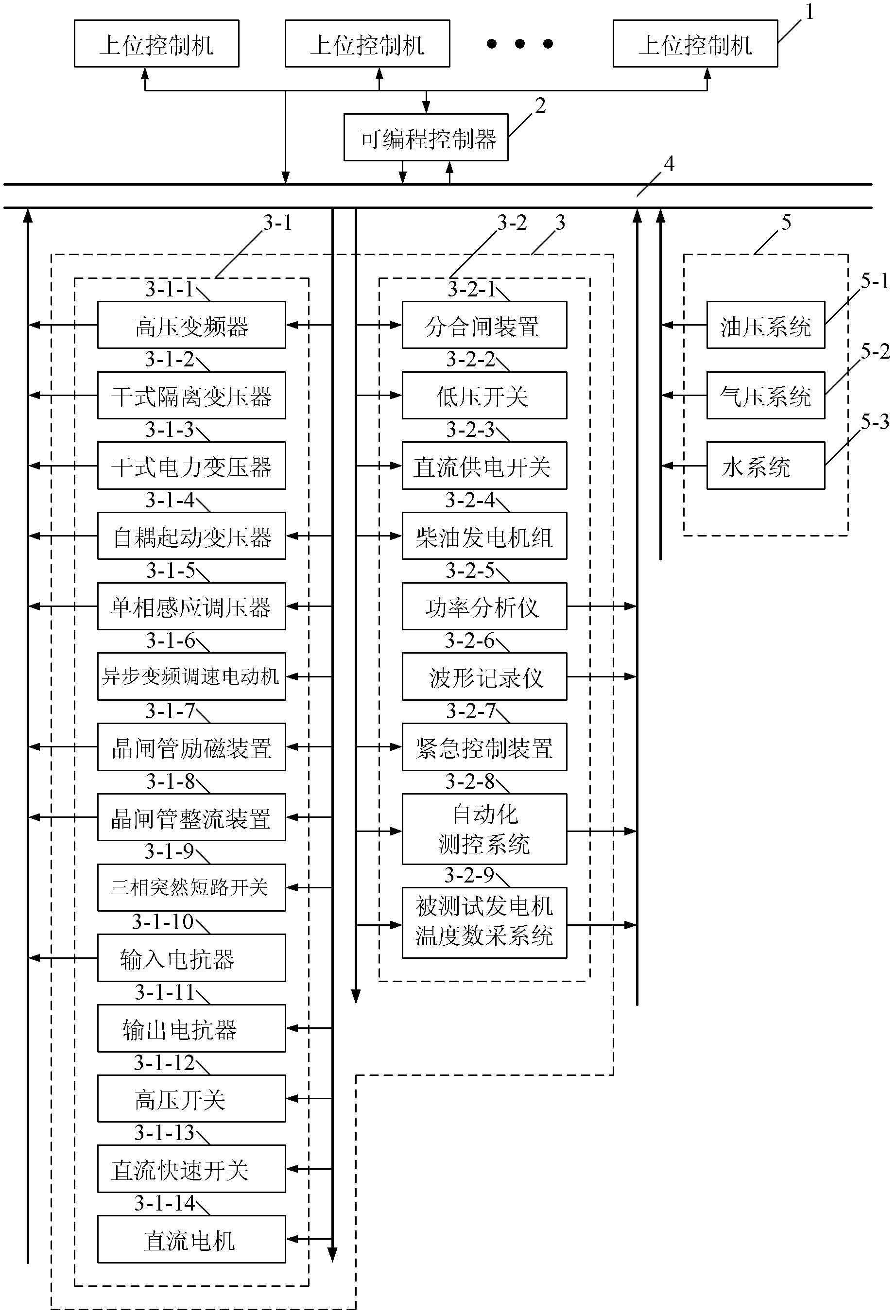

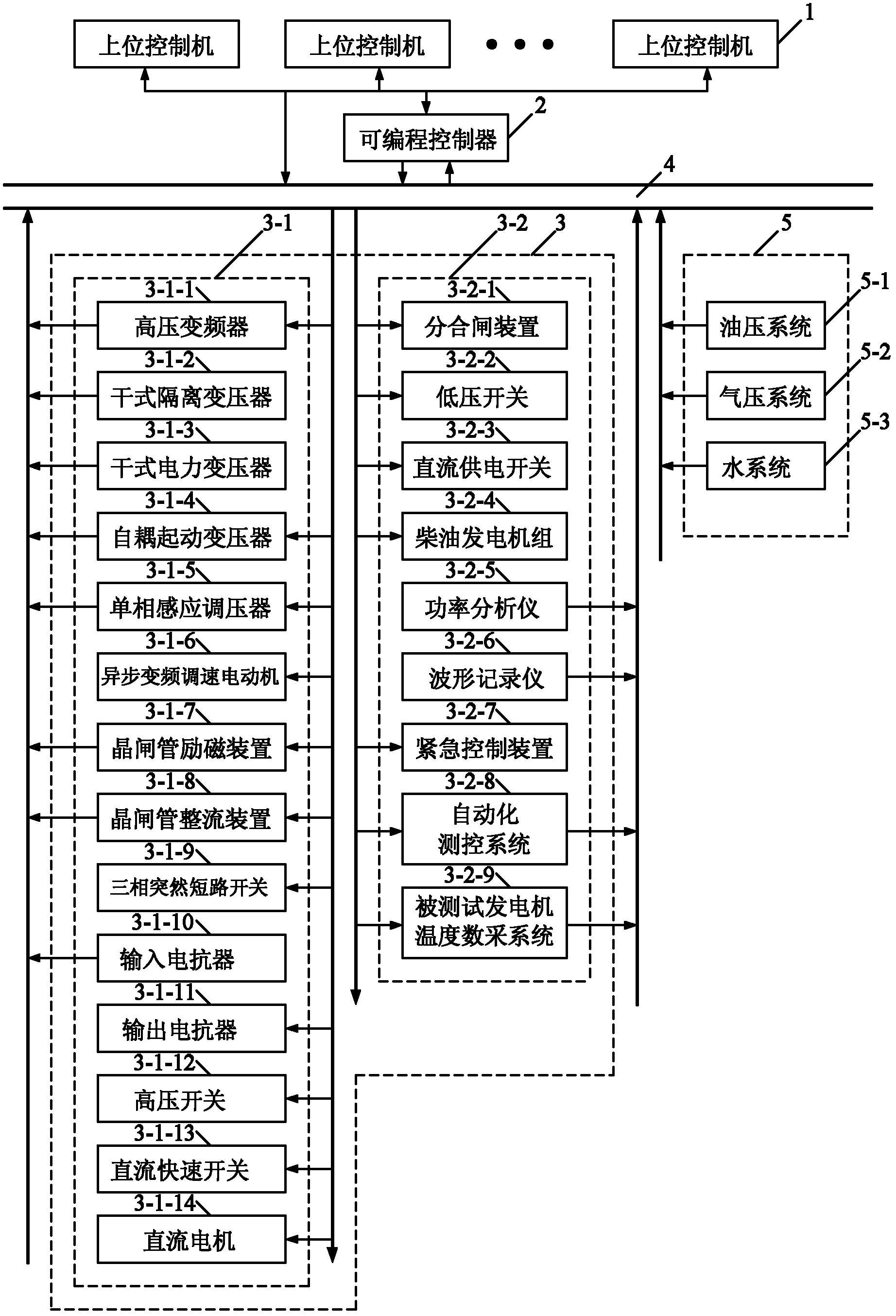

[0017] Specific implementation mode two: combination figure 2 Describe this embodiment, the first difference between this embodiment and the specific embodiment is that the electrical monitoring system 3 is composed of a high-voltage monitoring system 3-1 and a low-voltage monitoring system 3-2; the sampling data output of the high-voltage monitoring system 3-1 end is the first sampling data output end of the electrical monitoring system 3; the sampling data output end of the low-voltage monitoring system 3-2 is the second sampling data output end of the electrical monitoring system 3. Other compositions and connection methods are the same as those in Embodiment 1. The electrical monitoring system 3 mainly includes an electrical system, an electric drive system and an excitation system. The tester performs functions such as centralized control of the test device through the upper control machine 1, state monitoring, recording and analysis of relevant test data, and will Save...

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 2 Describe this embodiment. The difference between this embodiment and the second specific embodiment is that the high-voltage monitoring system 3-1 consists of a high-voltage frequency converter 3-1-1, a dry-type isolation transformer 3-1-2, and a dry-type power transformer 3- 1-3. Auto-coupling starter transformer 3-1-4, single-phase induction voltage regulator 3-1-5, asynchronous frequency conversion speed regulation motor 3-1-6, thyristor excitation device 3-1-7, thyristor rectifier device 3 -1-8, three-phase sudden short circuit switch 3-1-9, input reactor 3-1-10, output reactor 3-1-11, high voltage switch 3-1-12, DC fast switch 3-1-13 and DC motor 3-1-14; the sampling data output terminal of the high-voltage frequency converter 3-1-1 is connected to the high-voltage side data bus, and the control signal output terminal of the high-voltage frequency converter 3-1-1 is connected to the high-voltage side signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com