Steel solidus-liquidus temperature measurement method

A technology of liquidus temperature and measurement method, which is applied in the field of metal material detection, can solve the problems that cannot meet the actual production needs, and achieve the effect of high degree of automation and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Measurement of solid and liquidus temperature of 9Ni steel slab:

[0021] (1) Sample preparation: Take a disc-shaped 9Ni steel billet sample with a diameter of 5 mm and a thickness of 0.3 mm to ensure that there is no scale on the surface of the sample, clean it with alcohol solution, and dry it for later use. The main chemical components of 9Ni steel are C: 0.04 wt%, Si: 0.25 wt%, Mn: 0.60 wt%, Ni: 9.0 wt%, Al: 0.035 wt%.

[0022] (2) Select the standard material to complete the calibration of the temperature and sensitivity of the equipment according to the operating procedures of the differential thermal equipment.

[0023] (3) Experimental test: Calculate the liquidus temperature T of the 9Ni steel billet according to the chemical composition L * It is 1503°C, so the maximum heating temperature is set at 1530°C. Set the test program: heat up to 950°C at a rate of 20°C / min, then heat up to 1530°C at a rate of 10°C / min, and then drop to 950°C at a constant cooling ...

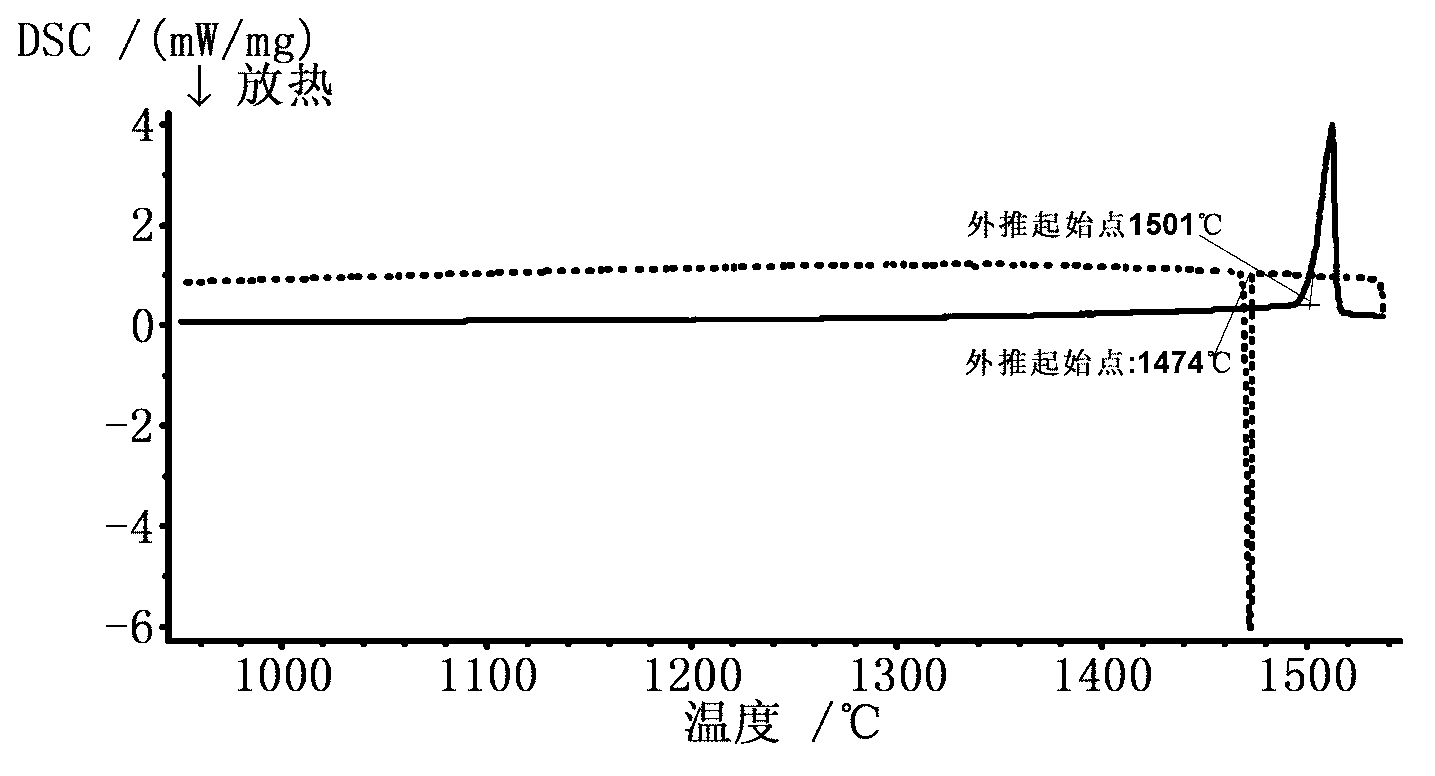

Embodiment 2

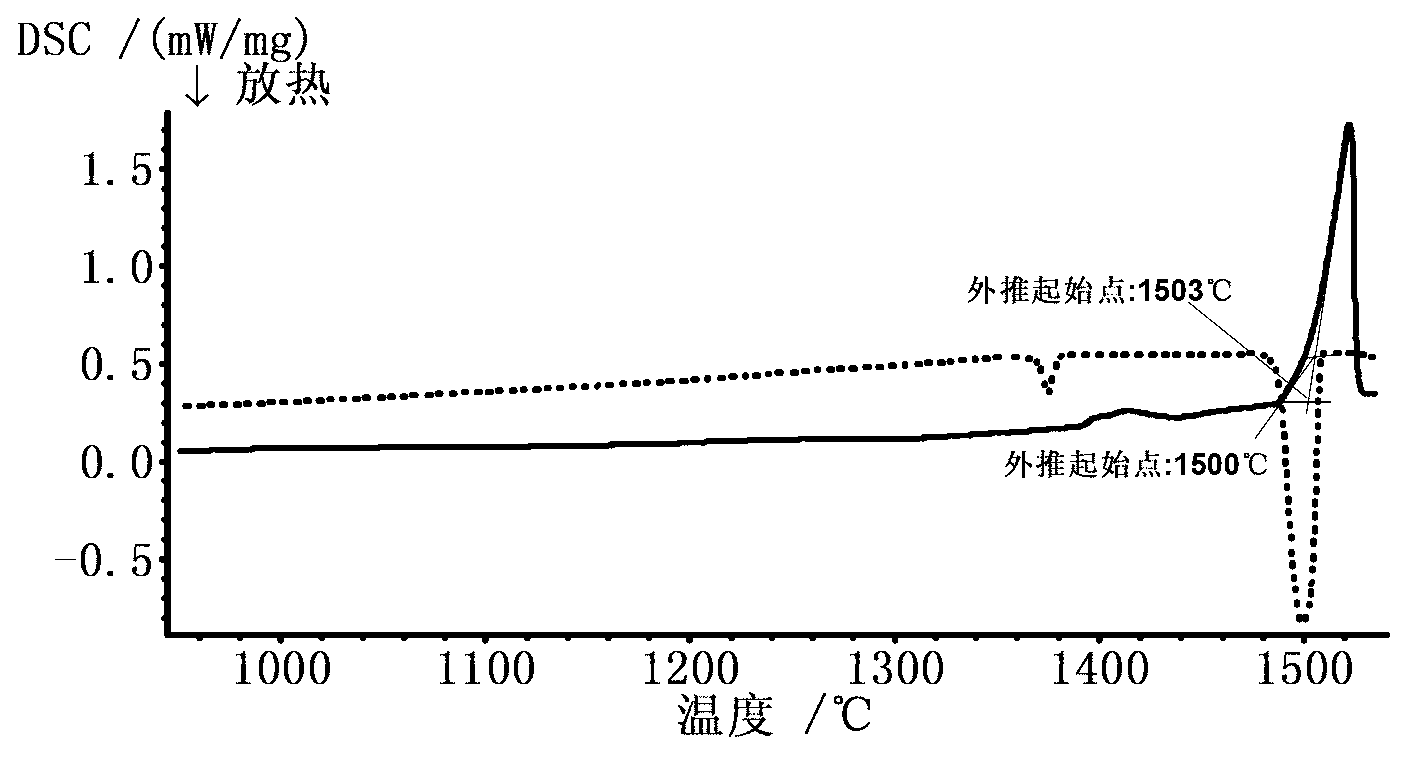

[0026] Measurement of solid and liquidus temperature of medium manganese steel slab:

[0027] (1) Sample preparation: Take a disc-shaped medium-manganese steel billet sample with a diameter of 4 mm and a thickness of 0.5 mm to ensure that there is no scale on the surface of the sample, clean it with alcohol solution, and dry it for later use. The main chemical components of medium manganese steel are C: 0.1 wt%, Mn: 5 wt%, Al: 1 wt%.

[0028] (2) Select the standard material to complete the calibration of the temperature and sensitivity of the equipment according to the operating procedures of the differential thermal equipment.

[0029] (3) Experimental test: Calculate the liquidus temperature T of the medium manganese steel billet according to the chemical composition L * It is 1506°C, so the maximum heating temperature is set at 1535°C. Set up the test program: heat up to 1535°C at a rate of 10°C / min, then drop to 950°C at a constant cooling rate of 10°C / min. Baseline a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com