Indoor rotary wheel rutting test machine for asphalt mixture

A technology for asphalt mixture and rutting test, which is used in material inspection products, analysis materials, and testing material hardness. The effect of error, improved test efficiency and short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

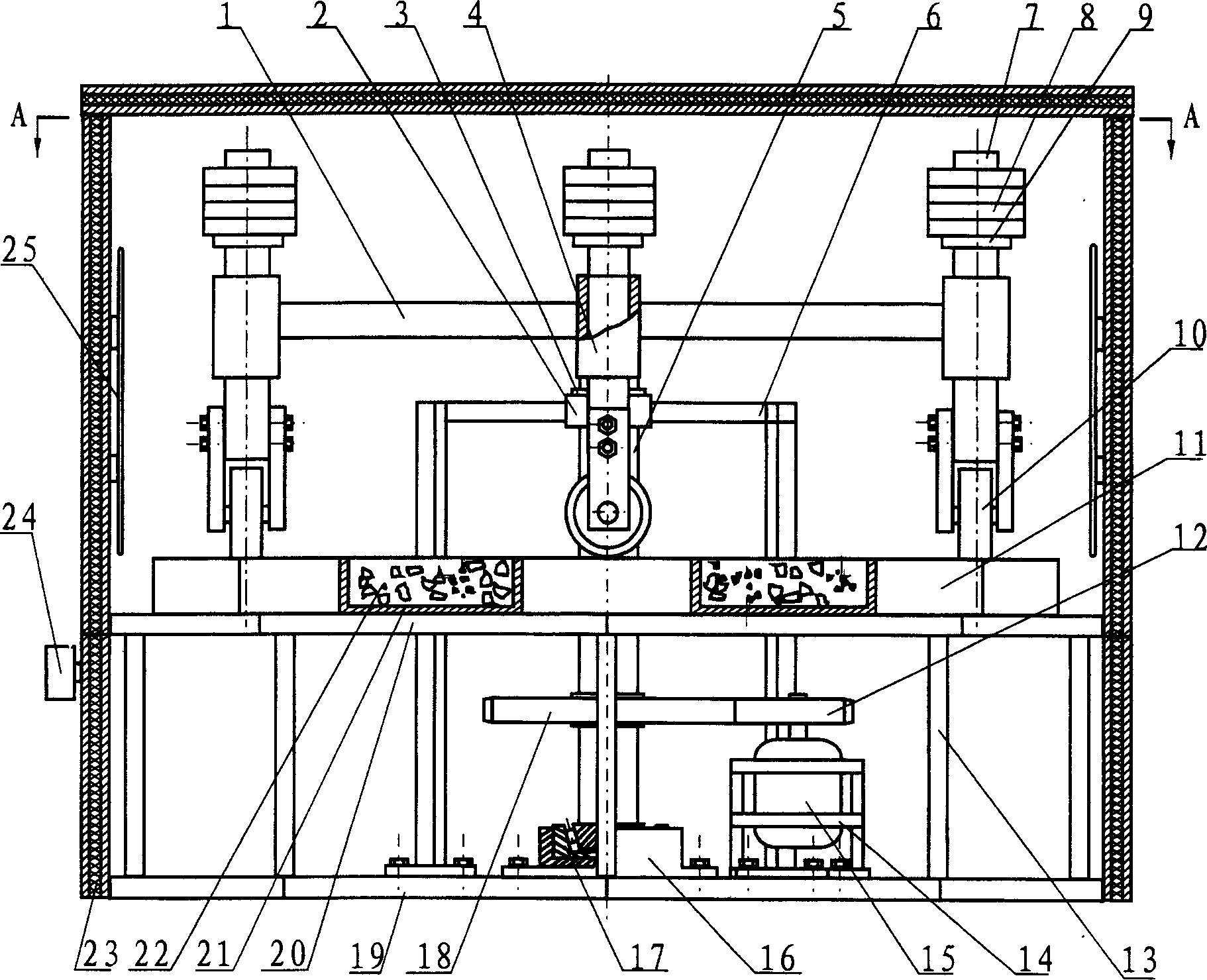

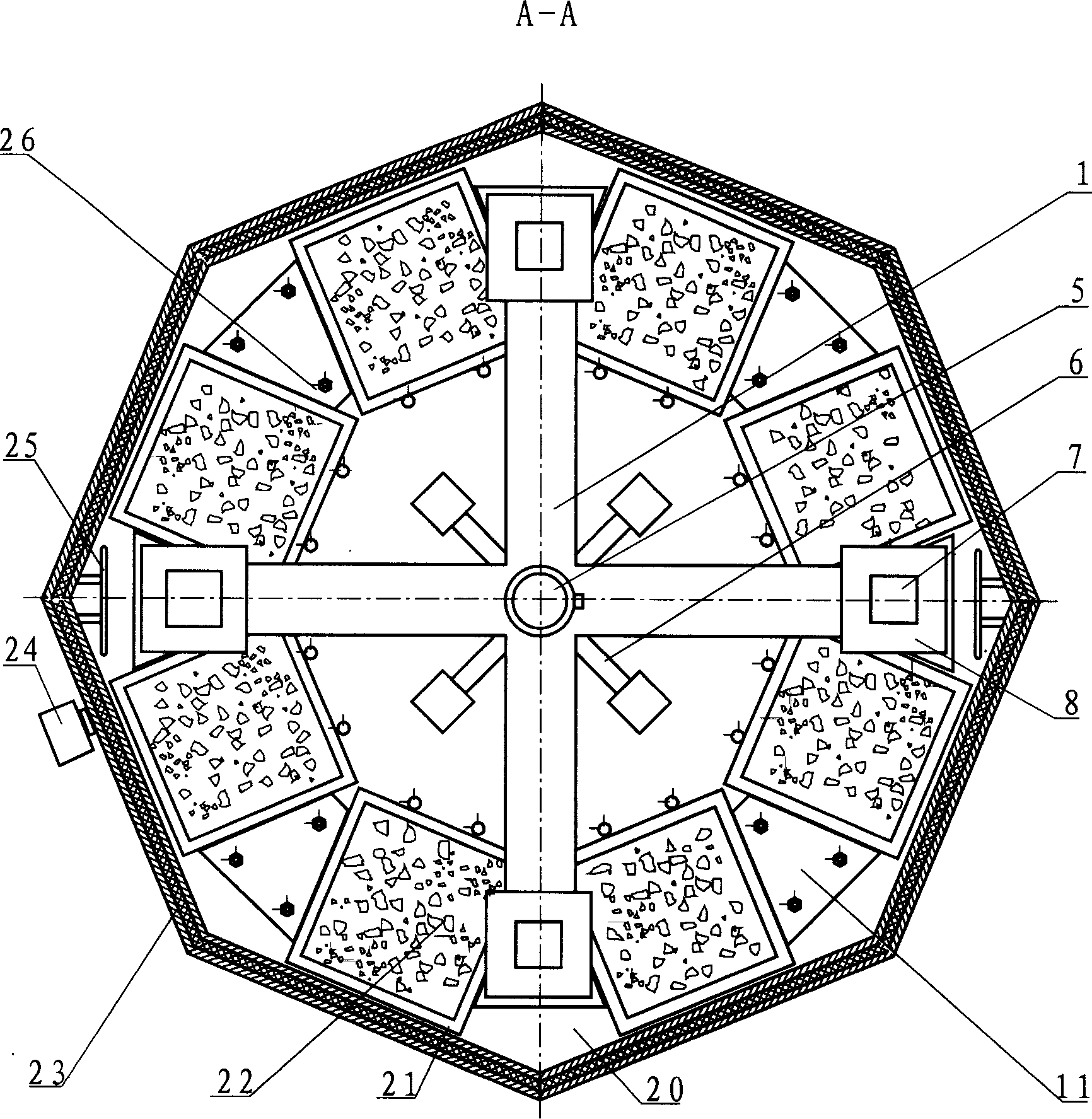

[0017] exist figure 1 , 2 Among them, the indoor rotary asphalt mixture rutting test machine of the present embodiment is composed of a rotating beam 1, a bearing sleeve 2, a bearing 3, a rubber wheel prop slide 4, a rotating shaft 5, a rotating shaft support 6, a rubber wheel prop 7, and a counterweight Block 8, counterweight support 9, rubber wheel 10, backing plate 11, motor gear 12, turntable pillar 13, motor frame 14, speed regulating motor 15, bearing support 16, rotating shaft bearing 17, rotating shaft gear 18, The test bench bottom plate 19, the test bench panel 20, the steel mold 21, the environment box 23, the temperature controller 24, the electric heating tube 25, and the limit column 26 are connected to form.

[0018] On the test bench base plate 19, a rotating shaft support 6, a rotating table pillar 13, a motor frame 14, a bearing support 16, and an environment box 23 are fixedly connected with a threaded fastening connector. On the motor frame 14, a speed re...

Embodiment 2

[0020] In this embodiment, the rotating beam 1 is a Pozier beam. Eight rubber wheel struts 7 are installed on the rotating beam 1 , and one rubber wheel 10 is installed at the lower end of each rubber wheel strut 7 . Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0022] In this embodiment, the rotating beam 1 is a straight beam, on which a rubber wheel strut 7 is mounted, and a rubber wheel 10 is mounted on the lower end of the rubber wheel strut 7 . Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com