Glass material ultrafast laser precision welding system and method

A precision welding and ultra-fast laser technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of insufficient precision of large-area bonding gaps on glass surfaces, low welding efficiency, and stress distribution of micro-welded layers and installation accuracy welding quality problems, to achieve the effect of eliminating welding defects and local cracks, improving service life, and enhancing the ability to resist high and low temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

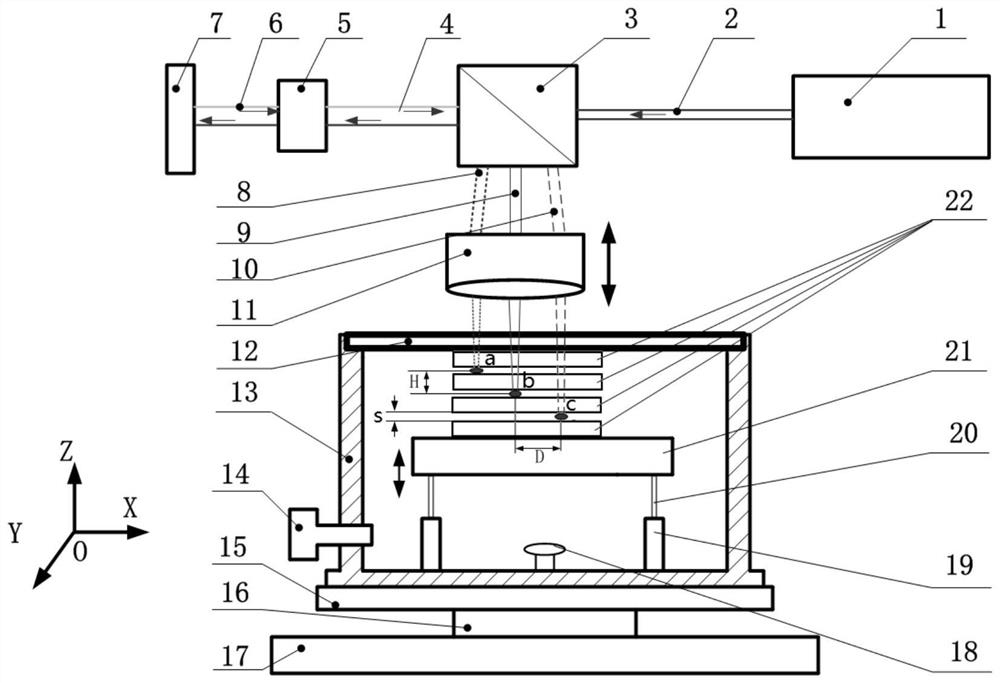

[0051] The ultra-fast laser precision welding system for glass materials includes an optical module, a clamping and preprocessing module, and a mechanical movement module.

[0052] 1) Optical module

[0053] Such as figure 1 As shown, the module includes an ultrafast laser 1 and a beam modulation unit composed of a polarization beam splitter 3 , a Faraday rotator 5 , a reflective beam modulator 7 and a telecentric microfocus lens 11 . After the ultrafast laser beam 2 generated from the ultrafast laser 1 passes through the polarization beam splitter 3, it is phase rotated by the Faraday rotator 5, and then phase modulated by the reflective beam modulator 7, and then divided into beams of different phases and different energies. Multiple beams of laser light are reflected back, pass through the Faraday rotator 5 , and then all are reflected to the telecentric micro-focus lens 11 by the polarizing beam splitter prism 3 . Among them, the third beam 8, the fourth beam 9 and the f...

Embodiment 2

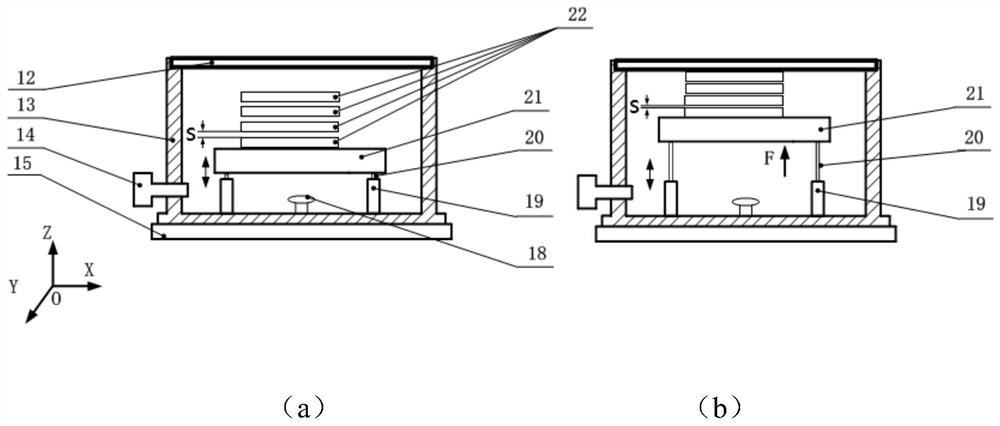

[0068] In this embodiment, the same glass material ultrafast laser precision welding system as in Embodiment 1 is used to perform one-time welding of three layers of glass plates.

[0069] The difference between the welding of the three-layer glass plates in this embodiment and that of Embodiment 1 is that the focus distribution of the beam split welding is different.

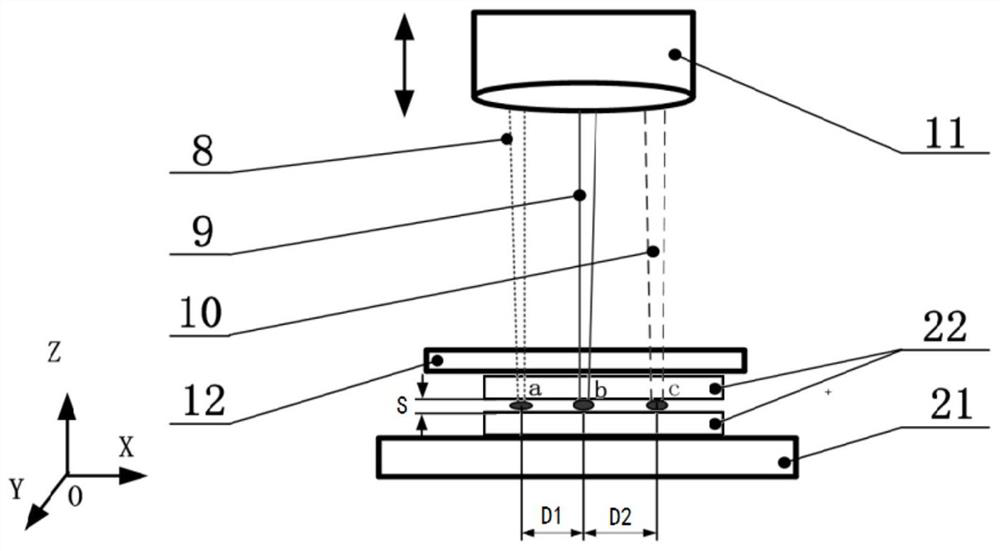

[0070] Such as Figure 4 As shown, it is a schematic diagram of focus distribution of three-layer glass laser space beam splitting welding. The laser beam is decomposed into a third beam 8, a fourth beam 9 and a fifth beam 10, and then focuses on the two bonding surfaces of the multi-layer glass 22 to be welded. exist Figure 4 (a) the focal points a and c are at the upper bonding surface of the multilayer glass to be welded 22, and the focal point b is at the lower bonding surface; Figure 4 In (b), the focus positions are reversed.

[0071] The multi-layer glass 22 to be welded is three layers of glass pla...

Embodiment 3

[0073] The difference from Embodiment 2 is that the multi-layer glass 22 to be welded in this embodiment is three layers of glass plates of different materials.

[0074] Such as Figure 6 As shown, the weldability of glass A and glass B is better, and the weldability of glass B and glass C is weaker, so it is always used Figure 6 The focus distribution mode shown is scanned, that is, double focus a and c are used at the interface between glass A and glass B, and single focus b is used at the interface between glass B and glass C. In addition, the energy ratio of the third beam 8, the fourth beam 9, and the fifth beam 10 needs to be adjusted according to the material properties. The energy of the focus b is stronger than the energy of the focus a and c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com