Soaking-resistant weather-resistant halogen-free flame-retardant polypropylene material, preparation method and application thereof

A flame retardant polypropylene and polypropylene resin technology, applied in the field of polymer modified materials, can solve the problems of deteriorated polypropylene mechanical properties, large addition amount, low flame retardant efficiency, etc., and reduce the amount of flame retardant and water absorption rate. Low, good carbonization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

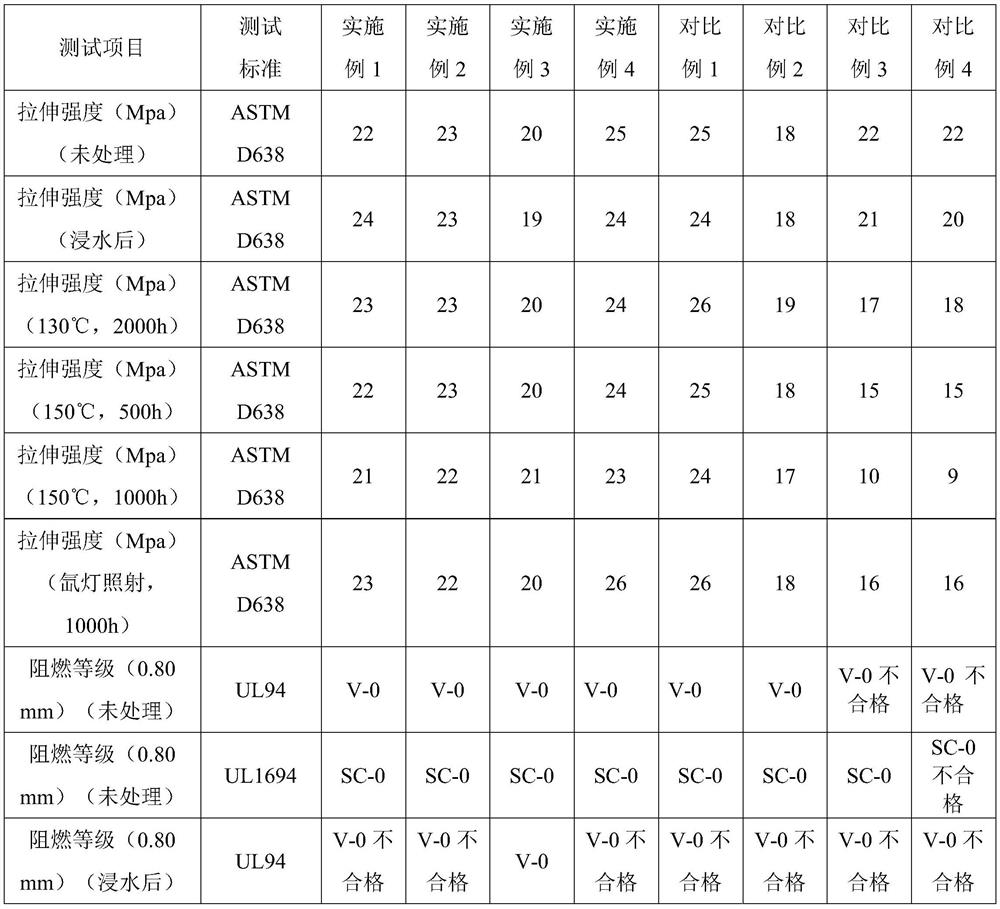

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and technical effect of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention. The specific process parameters and the like in the following examples are only examples of the appropriate range, that is, those skilled in the art can make a selection within the appropriate range through the description herein, and are not limited to the specific data exemplified below. The raw materials used in the examples can be obtained from conventional commercial channels unless otherwise specified.

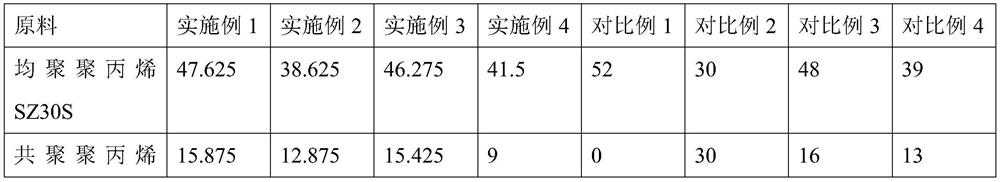

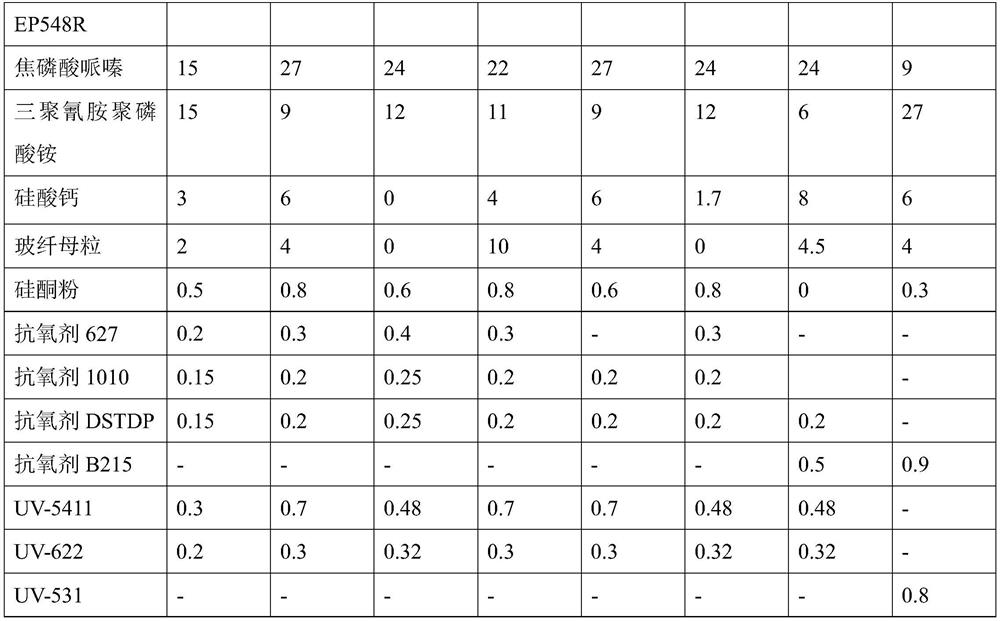

[0044] The raw material used in embodiment and comparative example comprises as follows:

[0045] Homopolypropylene: Homopolypropylene SZ30S, Maoming Petrochemical

[0046] Copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com