Method for manufacturing intelligent thermoregulation type functional yarn

A technology of intelligent temperature regulation and yarn, which is applied in the direction of fiber type, textile and paper making, fiber treatment, etc., to achieve the effects of convenient and flexible processing, improved mechanical properties, and obvious heat storage and temperature regulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1. Preparation of padding working solution:

[0031] A certain amount of binder and thickener is added to the phase-change microcapsule aqueous dispersion, and the mixture is evenly stirred to prepare a phase-change microcapsule functional finishing agent with a certain viscosity.

[0032] 2. Padding process:

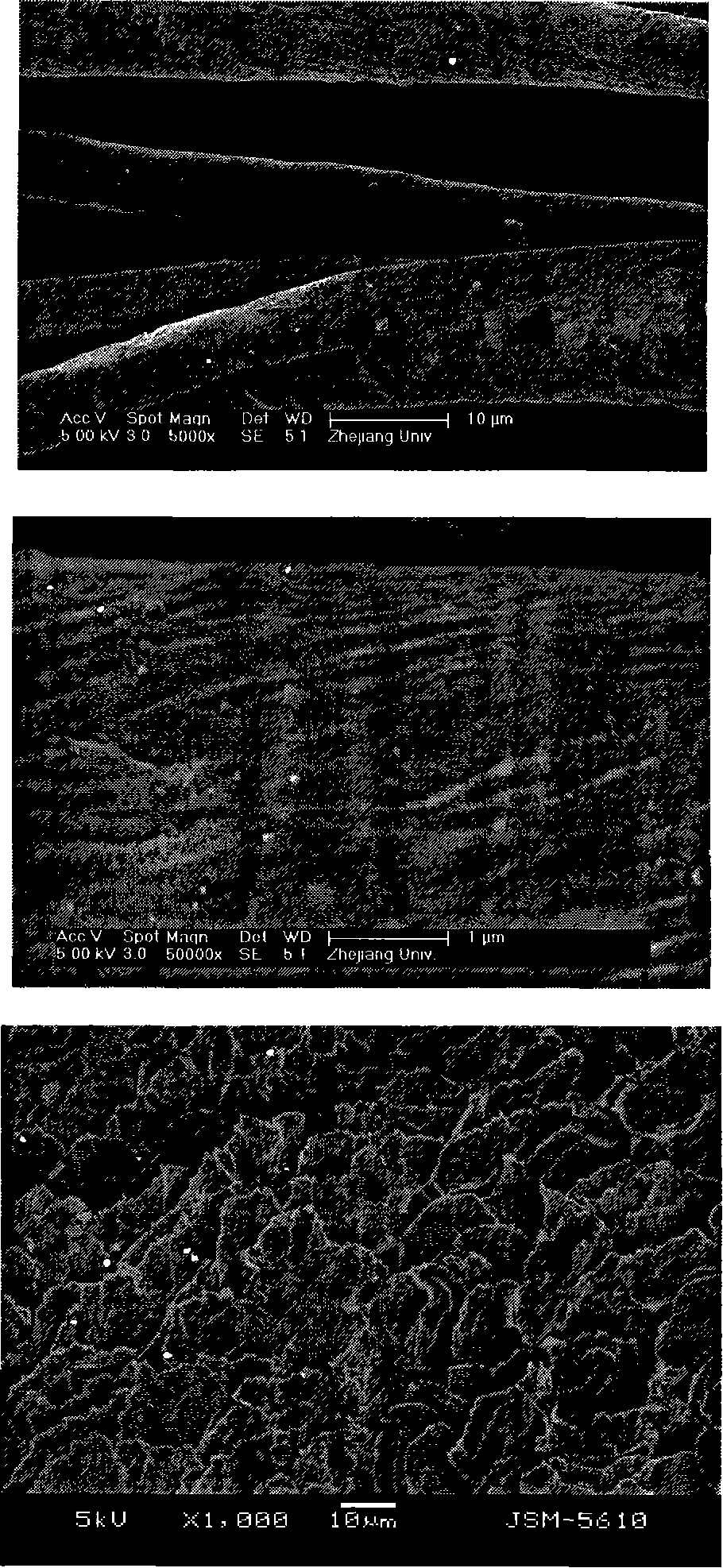

[0033] The yarn is immersed in the microcapsule finishing solution for 1 to 5 hours. After the yarn is fully swollen, the microcapsule not only adheres to the surface of the yarn, but also penetrates into the interior of the yarn.

[0034] 3. Pre-baking and baking:

[0035] The above-mentioned processed fabric is subjected to drying and setting treatment, pre-drying (50-90° C. × 1-2 hours) → baking (110-130° C. × 1-5 minutes). One is to remove moisture, and the other is to fix the microcapsules on the yarn by the adhesive after high-temperature baking, so as to improve the fastness to washing and rubbing.

[0036] 4. Weaving:

[0037] Finished yarns are made ...

Embodiment 1

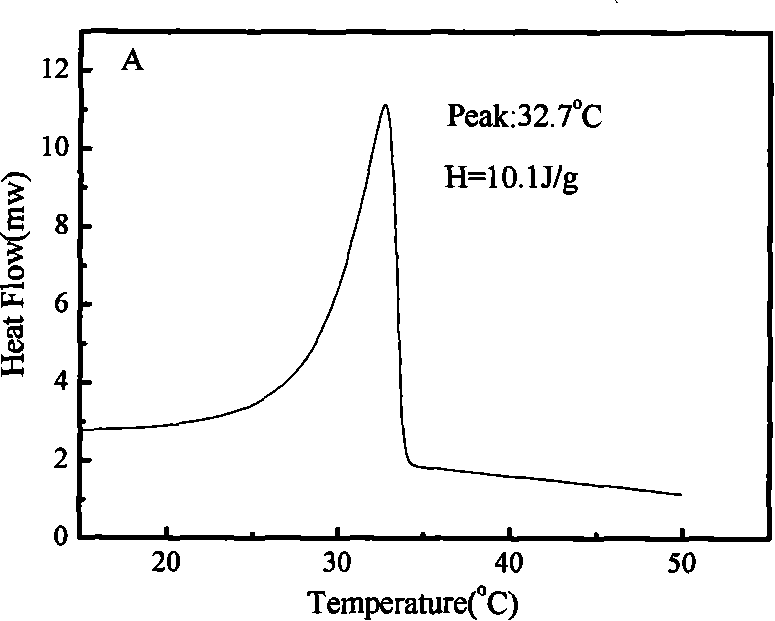

[0043] Working fluid formula: nano phase change capsule, phase transition temperature 33°C, average particle size 100nm, dosage 95.5%; binder (WX-351), concentration ratio 3%; thickener (HIT), dosage 1.5%.

[0044] Preparation process: After placing the weighed thickener in the container, under stirring, add the microcapsule dispersed emulsion in three batches, continue to stir for 30 minutes, add the binder, continue to stir evenly to make a viscous phase change microcapsule functional working solution.

[0045] Two-dipping and two-rolling process: pure cotton yarn (28.6×3tex); liquor ratio: 1:30, rolling off rate 150%, pre-baking (80°C×2h)→(baking 130°C×2min).

Embodiment 2

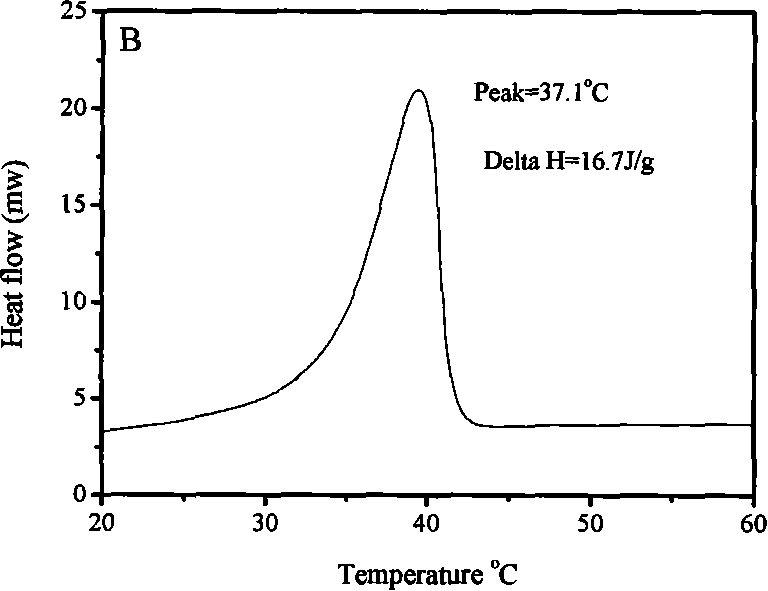

[0047] Working fluid formula: nano phase change capsules, phase transition temperature 37°C, average particle size 100nm, dosage 95.5%; binder (WX-351), dosage 3%; thickener (HIT), dosage 1.5%.

[0048] Preparation process: After placing the weighed thickener in the container, under stirring, add the microcapsule dispersed emulsion in three batches, continue to stir for 30 minutes, add the binder, continue to stir evenly to make a viscous phase change microcapsule functional working solution.

[0049] Two-dipping and two-rolling process: pure cotton yarn (28.6×3tex); liquor ratio: 1:30, 100% scrap rate, pre-baking (80°C×1.5h)→(baking 130°C×3min).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com