Radial gateleaf horizontal machining method and special tool

A processing method and technology for arc gates, which are applied to manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low manufacturing efficiency of door leaves, complex tooling structure, large cost input, etc., and achieve flexible and convenient processing and simplified process steps. , to ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

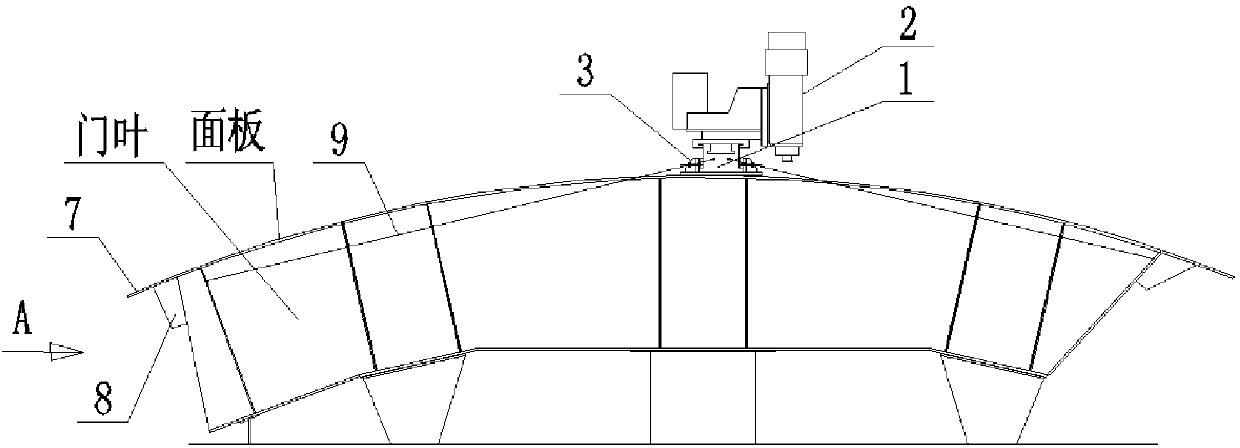

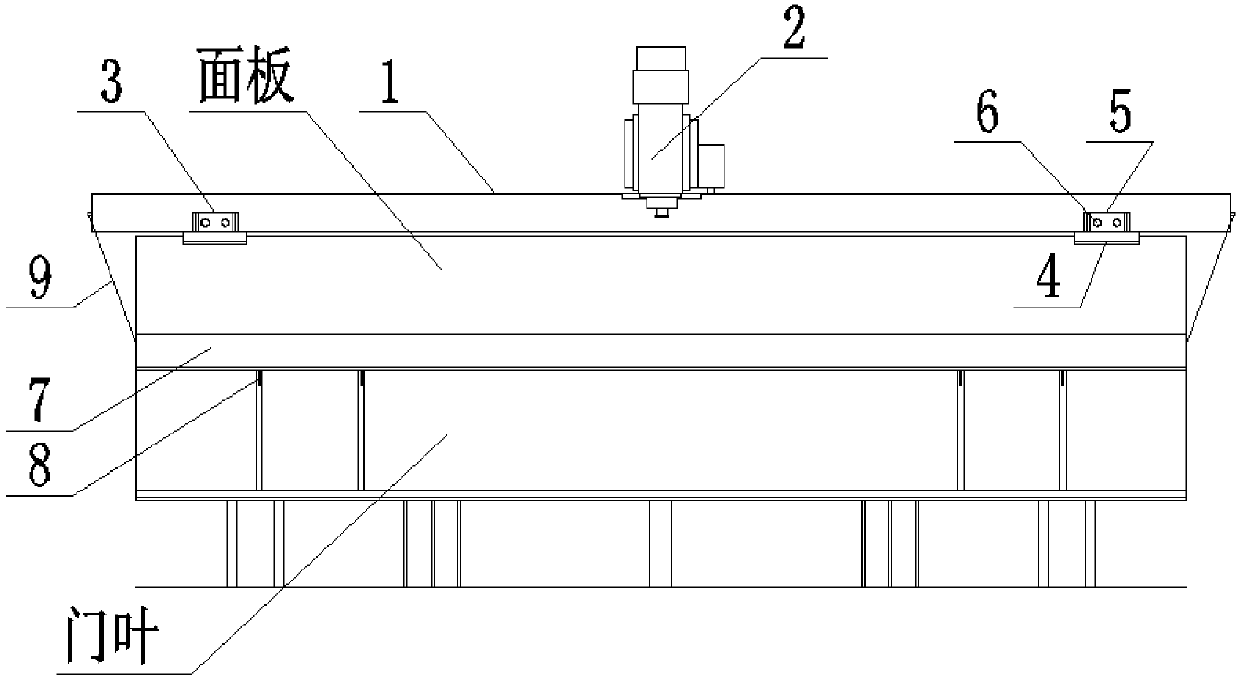

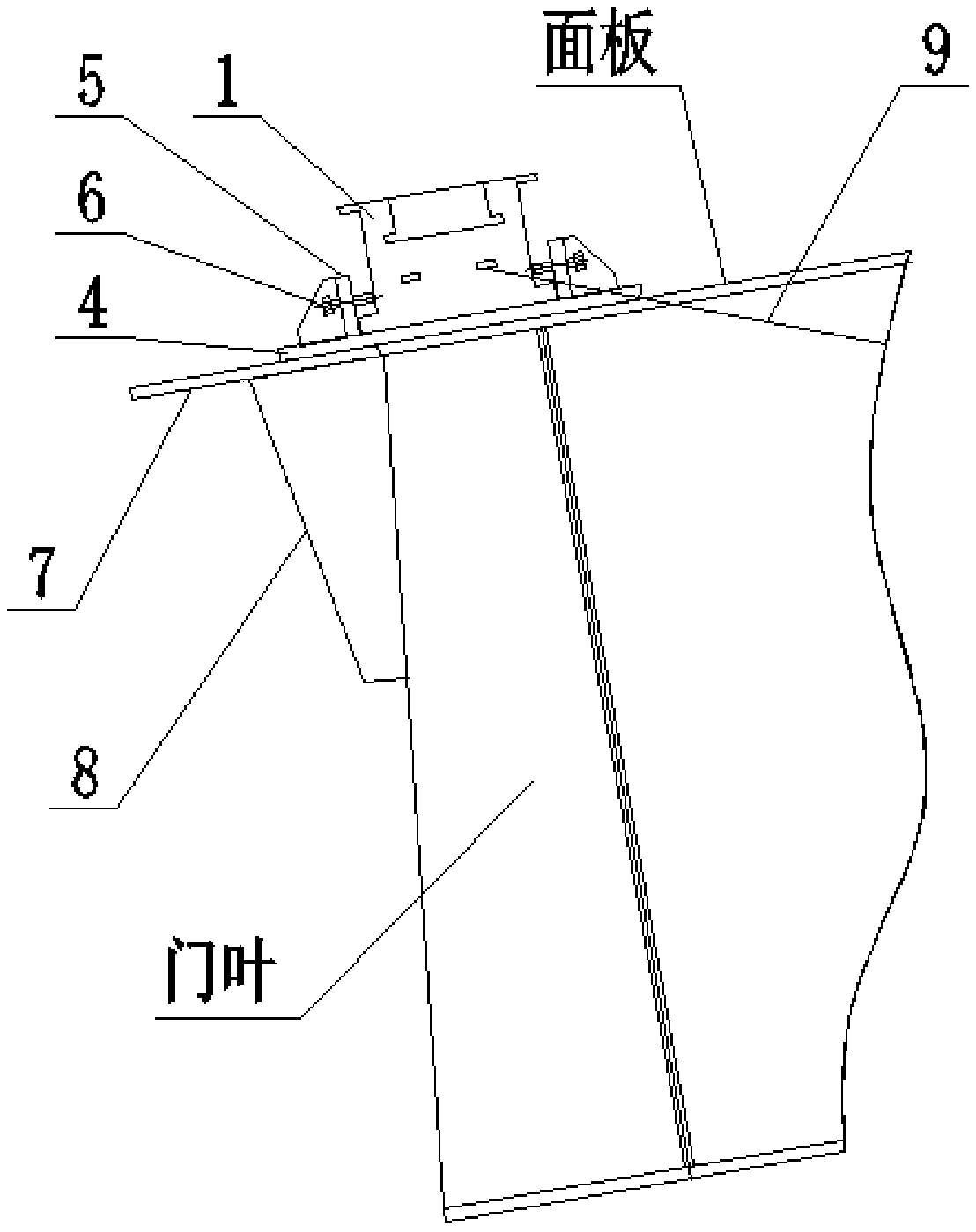

[0024] Such as Figures 1 to 3 As shown, a tooling for the horizontal processing method of curved gate leaves includes a processing track 1, a milling machine head 2 and a track backing plate assembly 3, and the milling machine head 2 is arranged on the processing track 1 and can be processed relatively The track 1 moves back and forth, and the track backing plate assembly 3 is arranged under the processing track 1; the length of the processing track 1 needs to be greater than the width of the processed door leaf, and the processing track 1 is in the shape of a long strip as a linear track, and the milling machine head 2. It is connected with the external power supply and the controller, and the controller can control the rotation of the cutter head on the milling machine head and the expansion and contraction of the cutter head, and control the reciprocating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com