Wet-type PU (polyurethane) thin film attached with TPU (thermoplastic polyurethane) thin film

A film and wet technology, applied in the field of wet PU plus TPU film, can solve the problems of elasticity, toughness, wear resistance, cold resistance, easy cracking, cracking, not enough environmental protection, etc., so that it is not easy to crack and break , good fixation, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

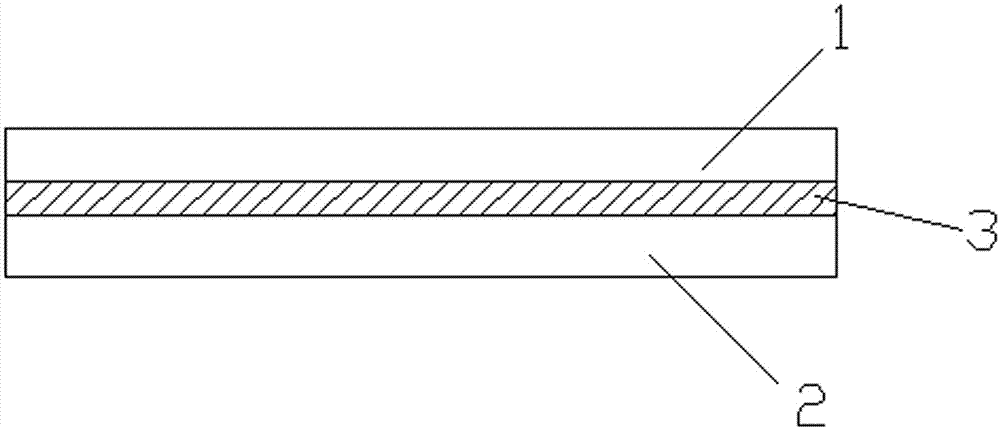

[0045] The wet PU attached TPU film provided by this embodiment includes a wet PU film layer 1 and a TPU film layer 2, and a hot melt adhesive layer 3 is also arranged between the wet PU film layer 1 and the TPU film layer 2.

[0046] Wherein, by weight percentage, TPU film comprises the following components:

[0047] Polyester thermoplastic polyurethane 93%;

[0048] Slip agent silicone oil 4%;

[0049] Antioxidant tetrakis[methylene-3,3',5-(di-tert-butyl-4-hydroxy-phenyl)propionate]pentaerythritol ester 0.5%;

[0050] Benzoic acid anti-ultraviolet agent 1%;

[0051] Stabilizer zinc stearate 1%;

[0052] Anti-hydrolysis agent carbodiimide 0.5%.

[0053] Among them, polyester thermoplastic polyurethane is prepared from polyester polyol, 4,4'-diphenylmethane diisocyanate (MDI) and 1,4-butanediol as raw materials.

Embodiment 2

[0055] The difference with embodiment 1 is:

[0056] By weight percentage, TPU film contains the following components:

[0057] Polyether thermoplastic polyurethane 88%;

[0058] Slip agent methyl silicone oil 5%;

[0059] Antioxidant N,N'-bis[[3-(3,5)-di-tert-butyl-4-hydroxyphenyl]propionyl]hexamethylenediamine 1%;

[0060] Xylene ketone anti-ultraviolet agent 2%;

[0061] Stabilizer calcium stearate 2%;

[0062] Anti-hydrolysis agent biscarbodiimide 2%.

[0063] Among them, polyether thermoplastic polyurethane is prepared from polytetrahydrofuran, toluene diisocyanate (TDI) and 1,4-butanediol as raw materials.

[0064] The rest are the same as those in the embodiments, and will not be repeated here.

Embodiment 3

[0066] The difference with embodiment 1 is:

[0067] By weight percentage, TPU film contains the following components:

[0068] Polyether thermoplastic polyurethane 98%;

[0069] Slip agent water-soluble silicone oil 1%;

[0070] Antioxidant tris[2,4-di-tert-butylphenyl]phosphite 0.2%;

[0071] Benzotriazole anti-ultraviolet agent 0.3%;

[0072] Stabilizer ethylene stearamide 0.3%;

[0073] Anti-hydrolysis agent polycarbodiimide 0.2%.

[0074] Among them, polyether thermoplastic polyurethane is prepared from polytetrahydrofuran, toluene diisocyanate (TDI) and 1,4-butanediol as raw materials.

[0075] The rest are the same as those in the embodiments, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com