Computing formula for processing rocker shaft eccentric toothed sector of numerical control gear shaping machine and processing method

A calculation formula and rocker shaft technology, applied to gear teeth, mechanical equipment, components with teeth, etc., can solve problems such as increasing the workload and working hours of operators, increasing manpower and material resources in manufacturing, and increasing product costs, etc., to achieve Flexible and convenient processing, reducing the adjustment of machine tools and the effect of fixture replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

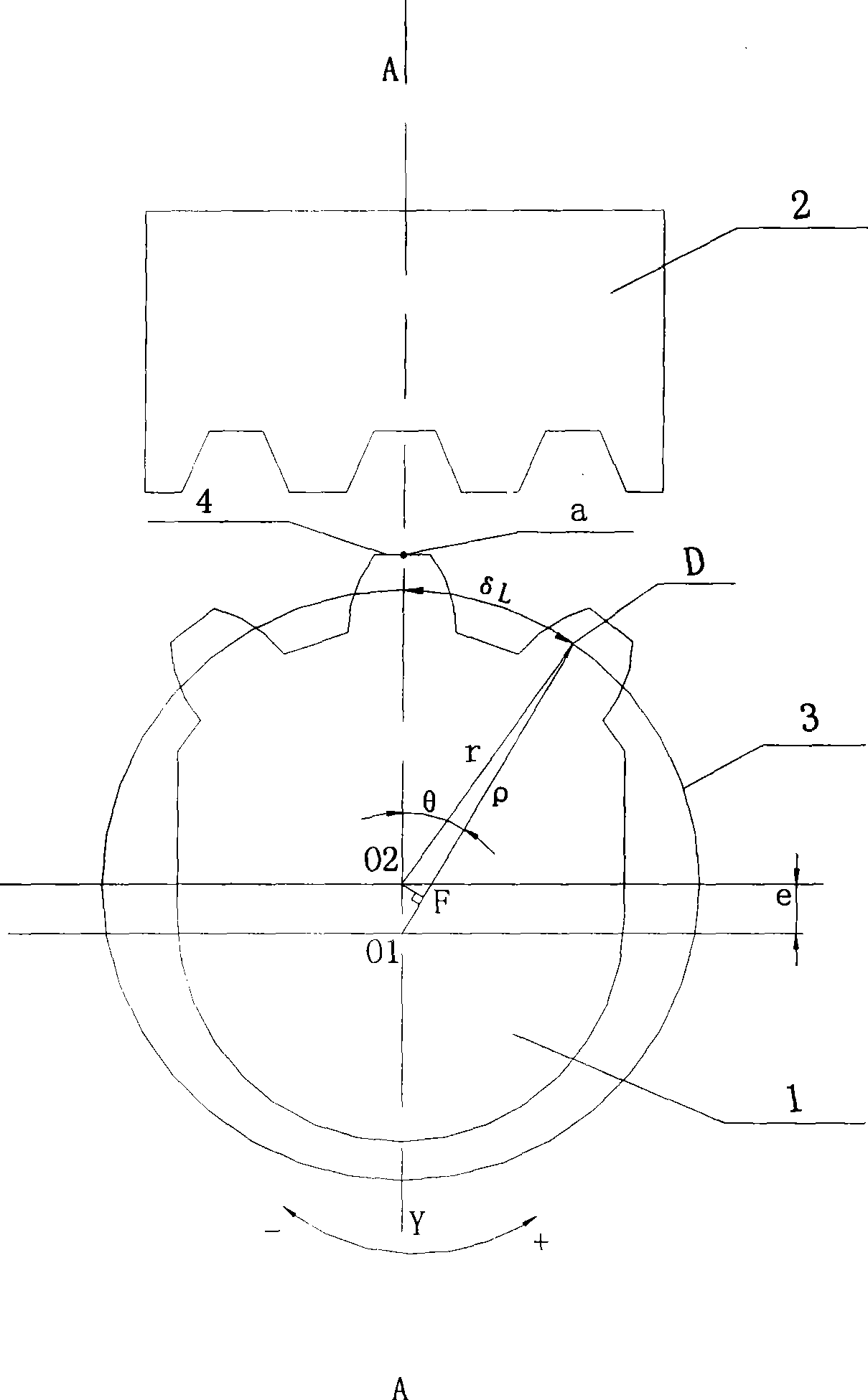

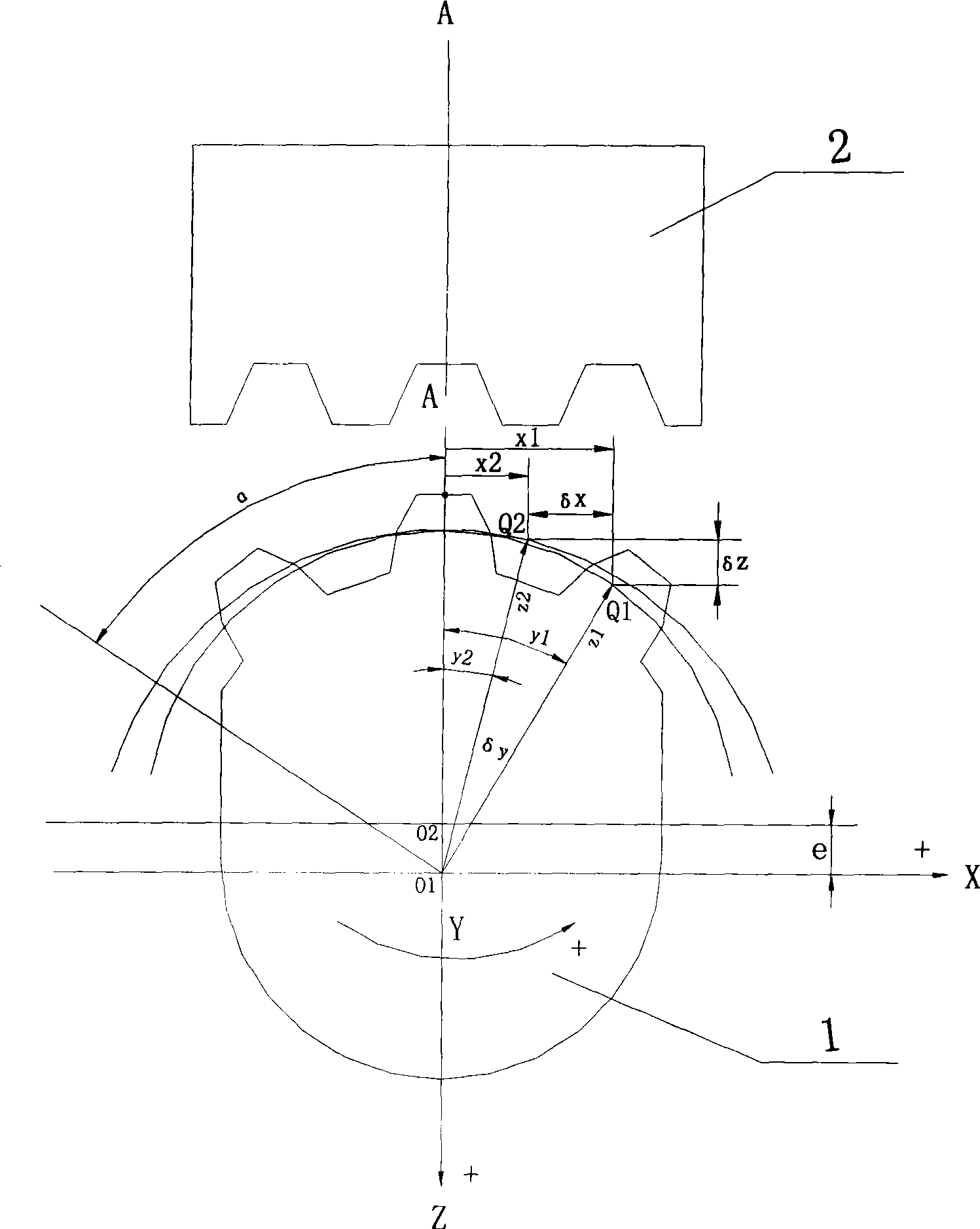

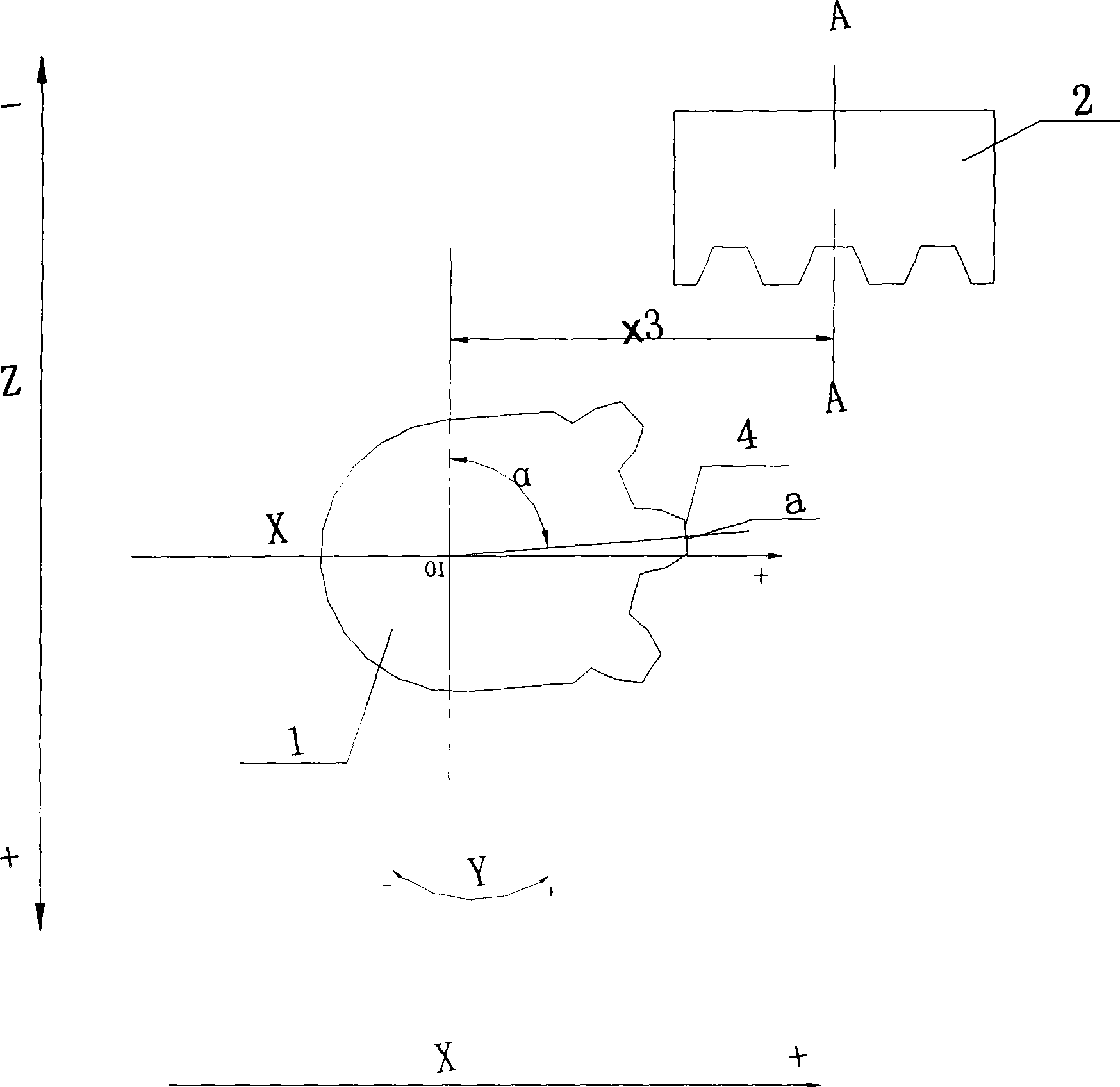

[0026] The implementation of the present invention will be further described in detail below with reference to the accompanying drawings.

[0027] The invention provides a method for machining an eccentric tooth sector of a rocker arm shaft by a numerically controlled gear sector gear shaping machine. The method includes a calculation formula stage for compiling a machining program and a processing flow stage according to the calculation formula:

[0028] 1. The calculation formula stage used to compile the processing program:

[0029] (1) Derive the calculation formula (1) of the radial radius ρ of the eccentric gear sector of the rocker shaft:

[0030] Use the following references:

[0031] 1. "Non-circular gear calculation method" on page 135 of the book "Non-circular gear and special gear transmission design";

[0032] 2. According to the general formula of trigonometric functions.

[0033] According to the above reference materials, the calculation formula of the radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com